Examining Opportunities Within Isocyanate Industry Revolutions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Industry Evolution and Objectives

The isocyanate industry has undergone significant evolution since its inception in the early 20th century. Initially developed for military applications during World War II, isocyanates quickly found their way into various industrial sectors due to their versatile chemical properties. The industry's growth has been primarily driven by the increasing demand for polyurethane products, which rely heavily on isocyanates as key raw materials.

Over the past few decades, the isocyanate industry has witnessed several technological advancements and market shifts. The development of new production processes, such as gas-phase technology, has improved efficiency and reduced environmental impact. Additionally, the industry has seen a gradual shift towards more sustainable and eco-friendly alternatives, responding to growing environmental concerns and regulatory pressures.

The current objectives of the isocyanate industry are multifaceted, focusing on both technological innovation and market expansion. One primary goal is to enhance production efficiency while minimizing environmental impact. This includes developing cleaner production processes, reducing energy consumption, and exploring bio-based alternatives to traditional petroleum-derived isocyanates.

Another key objective is to expand the application range of isocyanates beyond traditional sectors. While polyurethanes remain the largest consumer of isocyanates, there is a growing interest in exploring new markets, such as advanced coatings, adhesives, and specialty chemicals. This diversification strategy aims to reduce the industry's dependence on a single market segment and create new growth opportunities.

Safety and sustainability are also at the forefront of the industry's objectives. There is an ongoing effort to develop safer handling procedures and improve worker protection measures, given the potential health hazards associated with isocyanates. Furthermore, the industry is actively pursuing research into more environmentally friendly isocyanate-based products, including those with improved recyclability and biodegradability.

In terms of market dynamics, the isocyanate industry is aiming to navigate the challenges posed by fluctuating raw material prices and geopolitical uncertainties. Strategies to secure stable supply chains and optimize production costs are being prioritized to maintain competitiveness in the global market.

Looking ahead, the isocyanate industry is poised for further evolution, with a focus on innovation and sustainability. The development of novel isocyanate chemistries, exploration of renewable feedstocks, and advancements in application technologies are expected to shape the industry's future trajectory. As global demand for high-performance materials continues to grow, the isocyanate industry remains committed to meeting these needs while addressing environmental and safety concerns.

Over the past few decades, the isocyanate industry has witnessed several technological advancements and market shifts. The development of new production processes, such as gas-phase technology, has improved efficiency and reduced environmental impact. Additionally, the industry has seen a gradual shift towards more sustainable and eco-friendly alternatives, responding to growing environmental concerns and regulatory pressures.

The current objectives of the isocyanate industry are multifaceted, focusing on both technological innovation and market expansion. One primary goal is to enhance production efficiency while minimizing environmental impact. This includes developing cleaner production processes, reducing energy consumption, and exploring bio-based alternatives to traditional petroleum-derived isocyanates.

Another key objective is to expand the application range of isocyanates beyond traditional sectors. While polyurethanes remain the largest consumer of isocyanates, there is a growing interest in exploring new markets, such as advanced coatings, adhesives, and specialty chemicals. This diversification strategy aims to reduce the industry's dependence on a single market segment and create new growth opportunities.

Safety and sustainability are also at the forefront of the industry's objectives. There is an ongoing effort to develop safer handling procedures and improve worker protection measures, given the potential health hazards associated with isocyanates. Furthermore, the industry is actively pursuing research into more environmentally friendly isocyanate-based products, including those with improved recyclability and biodegradability.

In terms of market dynamics, the isocyanate industry is aiming to navigate the challenges posed by fluctuating raw material prices and geopolitical uncertainties. Strategies to secure stable supply chains and optimize production costs are being prioritized to maintain competitiveness in the global market.

Looking ahead, the isocyanate industry is poised for further evolution, with a focus on innovation and sustainability. The development of novel isocyanate chemistries, exploration of renewable feedstocks, and advancements in application technologies are expected to shape the industry's future trajectory. As global demand for high-performance materials continues to grow, the isocyanate industry remains committed to meeting these needs while addressing environmental and safety concerns.

Market Demand Analysis for Isocyanates

The isocyanate industry has experienced significant growth in recent years, driven by increasing demand across various end-use sectors. The global isocyanate market is primarily fueled by the expanding construction and automotive industries, which are major consumers of polyurethane products. In the construction sector, isocyanates are widely used in insulation materials, sealants, and adhesives, contributing to energy-efficient building solutions. The automotive industry utilizes isocyanates in the production of lightweight components, seat cushions, and coatings, aligning with the trend towards fuel-efficient vehicles.

The packaging industry has also emerged as a key driver for isocyanate demand, particularly in flexible packaging applications. The growing e-commerce sector and changing consumer preferences for convenient, lightweight packaging solutions have bolstered this trend. Additionally, the furniture and bedding industry continues to be a significant consumer of isocyanates, especially in the production of flexible and rigid foams for mattresses, sofas, and other household items.

Market analysis indicates a steady growth trajectory for isocyanates, with methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) being the most widely used types. The Asia-Pacific region, particularly China and India, is expected to lead market growth due to rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe maintain stable demand, driven by renovation activities and stringent energy efficiency regulations in the construction sector.

However, the isocyanate industry faces challenges related to environmental and health concerns. Regulatory pressures and growing awareness of the potential health hazards associated with isocyanate exposure have led to increased focus on developing safer alternatives and improving handling practices. This has created opportunities for bio-based and low-VOC isocyanate formulations, catering to the rising demand for sustainable and environmentally friendly products.

The market is also witnessing a shift towards specialty isocyanates, driven by the need for high-performance materials in niche applications such as aerospace, electronics, and medical devices. This trend is expected to create new growth avenues for isocyanate manufacturers and foster innovation in product development.

In conclusion, the isocyanate market demonstrates robust demand across multiple industries, with opportunities for growth in emerging economies and specialty applications. However, manufacturers must navigate environmental concerns and regulatory challenges while focusing on sustainable innovations to maintain long-term market viability.

The packaging industry has also emerged as a key driver for isocyanate demand, particularly in flexible packaging applications. The growing e-commerce sector and changing consumer preferences for convenient, lightweight packaging solutions have bolstered this trend. Additionally, the furniture and bedding industry continues to be a significant consumer of isocyanates, especially in the production of flexible and rigid foams for mattresses, sofas, and other household items.

Market analysis indicates a steady growth trajectory for isocyanates, with methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI) being the most widely used types. The Asia-Pacific region, particularly China and India, is expected to lead market growth due to rapid industrialization, urbanization, and increasing disposable incomes. North America and Europe maintain stable demand, driven by renovation activities and stringent energy efficiency regulations in the construction sector.

However, the isocyanate industry faces challenges related to environmental and health concerns. Regulatory pressures and growing awareness of the potential health hazards associated with isocyanate exposure have led to increased focus on developing safer alternatives and improving handling practices. This has created opportunities for bio-based and low-VOC isocyanate formulations, catering to the rising demand for sustainable and environmentally friendly products.

The market is also witnessing a shift towards specialty isocyanates, driven by the need for high-performance materials in niche applications such as aerospace, electronics, and medical devices. This trend is expected to create new growth avenues for isocyanate manufacturers and foster innovation in product development.

In conclusion, the isocyanate market demonstrates robust demand across multiple industries, with opportunities for growth in emerging economies and specialty applications. However, manufacturers must navigate environmental concerns and regulatory challenges while focusing on sustainable innovations to maintain long-term market viability.

Current Challenges in Isocyanate Production

The isocyanate industry faces several significant challenges in its current production processes. One of the primary concerns is the high energy consumption associated with isocyanate synthesis. The traditional production methods, particularly the phosgenation process, require substantial thermal energy inputs, leading to increased production costs and environmental impact. This energy-intensive nature of isocyanate production has become a focal point for industry stakeholders seeking to improve efficiency and reduce carbon footprints.

Another critical challenge is the reliance on fossil fuel-based raw materials. Isocyanates are predominantly derived from petroleum products, making the industry vulnerable to fluctuations in oil prices and supply chain disruptions. This dependency also raises sustainability concerns, as the industry seeks to align with global efforts to reduce reliance on non-renewable resources.

Safety considerations in isocyanate production remain a paramount challenge. The highly reactive nature of isocyanates, especially during the phosgenation process, poses significant risks to worker safety and requires stringent handling protocols. Exposure to isocyanates can lead to severe health issues, necessitating robust safety measures and continuous improvement in production technologies to minimize potential hazards.

Environmental concerns also present ongoing challenges for the isocyanate industry. The production process generates various by-products and emissions that require careful management to comply with increasingly stringent environmental regulations. Addressing these environmental impacts while maintaining production efficiency is a delicate balance that manufacturers must navigate.

The industry also grapples with the challenge of product quality consistency. Ensuring uniform quality across batches is crucial for meeting the diverse requirements of end-users in various sectors, from automotive to construction. Variations in raw material quality and process conditions can lead to inconsistencies in the final product, necessitating advanced process control and quality assurance measures.

Lastly, the isocyanate industry faces the challenge of adapting to changing market demands and regulations. As sustainability becomes a key focus across industries, there is growing pressure to develop bio-based alternatives and more environmentally friendly production methods. This shift requires significant investment in research and development, as well as potential modifications to existing production infrastructure.

Another critical challenge is the reliance on fossil fuel-based raw materials. Isocyanates are predominantly derived from petroleum products, making the industry vulnerable to fluctuations in oil prices and supply chain disruptions. This dependency also raises sustainability concerns, as the industry seeks to align with global efforts to reduce reliance on non-renewable resources.

Safety considerations in isocyanate production remain a paramount challenge. The highly reactive nature of isocyanates, especially during the phosgenation process, poses significant risks to worker safety and requires stringent handling protocols. Exposure to isocyanates can lead to severe health issues, necessitating robust safety measures and continuous improvement in production technologies to minimize potential hazards.

Environmental concerns also present ongoing challenges for the isocyanate industry. The production process generates various by-products and emissions that require careful management to comply with increasingly stringent environmental regulations. Addressing these environmental impacts while maintaining production efficiency is a delicate balance that manufacturers must navigate.

The industry also grapples with the challenge of product quality consistency. Ensuring uniform quality across batches is crucial for meeting the diverse requirements of end-users in various sectors, from automotive to construction. Variations in raw material quality and process conditions can lead to inconsistencies in the final product, necessitating advanced process control and quality assurance measures.

Lastly, the isocyanate industry faces the challenge of adapting to changing market demands and regulations. As sustainability becomes a key focus across industries, there is growing pressure to develop bio-based alternatives and more environmentally friendly production methods. This shift requires significant investment in research and development, as well as potential modifications to existing production infrastructure.

Current Isocyanate Production Methods

01 Synthesis and properties of isocyanates

Isocyanates are a class of highly reactive compounds characterized by the -N=C=O functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or its derivatives. Various methods have been developed to control the reactivity and improve the handling of isocyanates in industrial applications.- Synthesis and properties of isocyanates: Isocyanates are a class of highly reactive compounds characterized by the -NCO functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl-containing compounds. Their properties, such as reactivity and stability, are crucial for various industrial applications.

- Applications of isocyanates in coatings and adhesives: Isocyanates play a significant role in the formulation of high-performance coatings and adhesives. They react with polyols to form polyurethanes, which offer excellent durability, chemical resistance, and adhesion properties. These materials find applications in automotive coatings, industrial finishes, and structural adhesives.

- Isocyanate-based foam technologies: Isocyanates are crucial components in the production of polyurethane foams. These foams are used in various applications, including insulation, cushioning, and packaging. The reaction between isocyanates and polyols, combined with blowing agents, creates the cellular structure of the foam. Different formulations and processing techniques can yield foams with varying properties, such as rigidity, flexibility, and density.

- Safety and handling of isocyanates: Due to their high reactivity, isocyanates pose potential health and safety risks. Proper handling, storage, and use of personal protective equipment are essential when working with these compounds. Exposure to isocyanates can cause respiratory irritation and sensitization. Implementing engineering controls, such as ventilation systems, and following strict safety protocols are crucial in industrial settings where isocyanates are used.

- Environmental considerations and alternatives to isocyanates: With increasing environmental awareness, there is growing interest in developing more sustainable alternatives to traditional isocyanate-based systems. This includes the exploration of bio-based isocyanates, non-isocyanate polyurethanes, and other environmentally friendly chemistries. Research is focused on maintaining or improving performance while reducing the environmental impact and potential health risks associated with conventional isocyanates.

02 Applications of isocyanates in coatings and adhesives

Isocyanates play a crucial role in the formulation of high-performance coatings and adhesives. They react with polyols to form polyurethanes, which offer excellent durability, chemical resistance, and adhesion properties. Modified isocyanates and isocyanate-terminated prepolymers are often used to tailor the curing behavior and final properties of the coating or adhesive system.Expand Specific Solutions03 Isocyanate-based foam production

Isocyanates are essential components in the production of polyurethane foams. The reaction between isocyanates and polyols, in the presence of blowing agents and catalysts, leads to the formation of cellular structures with varying densities and properties. Techniques have been developed to control the foam morphology, improve insulation properties, and enhance fire resistance in applications such as construction materials and automotive parts.Expand Specific Solutions04 Safety and handling of isocyanates

Due to their high reactivity and potential health hazards, proper safety measures and handling procedures are crucial when working with isocyanates. This includes the development of low-emission formulations, encapsulation techniques, and personal protective equipment. Research has focused on reducing the volatility of isocyanates and creating safer alternatives while maintaining their desirable properties in various applications.Expand Specific Solutions05 Isocyanate-free technologies

With increasing environmental and health concerns, there is growing interest in developing isocyanate-free alternatives for traditional polyurethane applications. These include non-isocyanate polyurethanes (NIPUs) based on cyclic carbonates and amines, as well as other polymer systems that can mimic the properties of isocyanate-based materials. Research in this area aims to provide more sustainable and safer options for various industries.Expand Specific Solutions

Key Players in Isocyanate Manufacturing

The isocyanate industry is currently in a mature growth phase, with a global market size expected to reach $38 billion by 2025. The technology landscape is characterized by ongoing innovations in sustainable production methods and bio-based alternatives. Key players like BASF, Covestro, and Wanhua Chemical are driving advancements in eco-friendly isocyanates, focusing on reducing environmental impact and improving energy efficiency. The market is highly competitive, with established companies investing heavily in R&D to maintain their market positions. Emerging trends include the development of non-toxic alternatives and the integration of smart manufacturing processes to enhance production efficiency and product quality.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate technologies to address sustainability challenges in the industry. Their approach includes the use of bio-based raw materials and the development of novel catalysts for more efficient isocyanate production[1]. BASF has also introduced water-based polyurethane dispersions that reduce VOC emissions and improve worker safety[2]. Additionally, they have invested in research on isocyanate-free technologies, exploring alternative chemistries that could potentially replace traditional isocyanates in certain applications[3].

Strengths: Strong R&D capabilities, diverse product portfolio, and global presence. Weaknesses: High dependence on petrochemical feedstocks and potential regulatory challenges related to isocyanate handling.

Covestro Deutschland AG

Technical Solution: Covestro has been at the forefront of isocyanate industry revolutions with their focus on sustainable and circular economy solutions. They have developed partially bio-based isocyanates, reducing the carbon footprint of their products[4]. Covestro's innovative INSQIN® technology for waterborne polyurethane (PU) coatings eliminates the need for organic solvents in textile coating processes, significantly reducing environmental impact[5]. Furthermore, they are investing in carbon capture and utilization (CCU) technologies to produce aniline, a key precursor for MDI isocyanates, from CO2, potentially revolutionizing the industry's raw material sourcing[6].

Strengths: Strong focus on sustainability, innovative technologies, and circular economy solutions. Weaknesses: High capital investment required for new technologies and potential market resistance to novel solutions.

Innovative Isocyanate Synthesis Approaches

Modified isocyanates

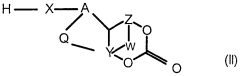

PatentWO2000020477A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable and reacts only under specific conditions, allowing for controlled crosslinking reactions without releasing isocyanate functions prematurely, using cyclic carbonates to form stable polyisocyanates that can react with nucleophilic compounds to create coatings and foams.

Modified isocyanates

PatentInactiveEP1129120A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable and only reacts under appropriate conditions, allowing for crosslinking reactions without the drawbacks of free isocyanate groups, such as those formed by reacting polyisocyanates with cyclic carbonates, resulting in stable polyisocyanates that can form coatings and polymers without expansion, and can be used in industrial structures like paints or varnishes.

Environmental Impact of Isocyanate Industry

The isocyanate industry, while crucial for various manufacturing processes, has significant environmental implications that require careful consideration. The production and use of isocyanates contribute to several environmental concerns, including air pollution, water contamination, and soil degradation. One of the primary issues is the release of volatile organic compounds (VOCs) during manufacturing and application processes, which can lead to the formation of ground-level ozone and contribute to smog formation in urban areas.

Water pollution is another critical environmental impact associated with the isocyanate industry. Improper disposal of waste products and accidental spills can contaminate water sources, potentially harming aquatic ecosystems and posing risks to human health. The persistence of certain isocyanate compounds in water bodies can lead to long-term ecological damage and bioaccumulation in the food chain.

Soil contamination is also a concern, particularly in areas surrounding production facilities or where isocyanate-containing products are improperly disposed of. This can result in the degradation of soil quality, affecting plant growth and potentially entering the groundwater system. The long-term effects of soil contamination can be particularly challenging to mitigate and may require extensive remediation efforts.

The industry's carbon footprint is another significant environmental consideration. The energy-intensive production processes of isocyanates contribute to greenhouse gas emissions, exacerbating climate change concerns. As global efforts to reduce carbon emissions intensify, the isocyanate industry faces increasing pressure to adopt more sustainable practices and explore alternative production methods.

Waste management in the isocyanate industry presents additional environmental challenges. The disposal of by-products, unused materials, and end-of-life products containing isocyanates requires specialized handling to prevent environmental contamination. Improper disposal can lead to the release of toxic substances into the environment, posing risks to both ecosystems and human health.

To address these environmental impacts, the isocyanate industry is increasingly focusing on developing more sustainable production methods, improving waste management practices, and exploring bio-based alternatives. Innovations in green chemistry and circular economy principles are being applied to reduce the environmental footprint of isocyanate production and use. Additionally, stricter regulations and industry standards are being implemented to minimize environmental risks and promote responsible practices throughout the supply chain.

Water pollution is another critical environmental impact associated with the isocyanate industry. Improper disposal of waste products and accidental spills can contaminate water sources, potentially harming aquatic ecosystems and posing risks to human health. The persistence of certain isocyanate compounds in water bodies can lead to long-term ecological damage and bioaccumulation in the food chain.

Soil contamination is also a concern, particularly in areas surrounding production facilities or where isocyanate-containing products are improperly disposed of. This can result in the degradation of soil quality, affecting plant growth and potentially entering the groundwater system. The long-term effects of soil contamination can be particularly challenging to mitigate and may require extensive remediation efforts.

The industry's carbon footprint is another significant environmental consideration. The energy-intensive production processes of isocyanates contribute to greenhouse gas emissions, exacerbating climate change concerns. As global efforts to reduce carbon emissions intensify, the isocyanate industry faces increasing pressure to adopt more sustainable practices and explore alternative production methods.

Waste management in the isocyanate industry presents additional environmental challenges. The disposal of by-products, unused materials, and end-of-life products containing isocyanates requires specialized handling to prevent environmental contamination. Improper disposal can lead to the release of toxic substances into the environment, posing risks to both ecosystems and human health.

To address these environmental impacts, the isocyanate industry is increasingly focusing on developing more sustainable production methods, improving waste management practices, and exploring bio-based alternatives. Innovations in green chemistry and circular economy principles are being applied to reduce the environmental footprint of isocyanate production and use. Additionally, stricter regulations and industry standards are being implemented to minimize environmental risks and promote responsible practices throughout the supply chain.

Safety Regulations in Isocyanate Handling

Safety regulations in the isocyanate industry have evolved significantly over the years, driven by the need to protect workers and the environment from the potential hazards associated with these chemicals. The Occupational Safety and Health Administration (OSHA) in the United States has established comprehensive guidelines for the handling, storage, and use of isocyanates in industrial settings.

One of the primary safety concerns in isocyanate handling is exposure control. Employers are required to implement engineering controls, such as closed systems and local exhaust ventilation, to minimize worker exposure to isocyanate vapors and aerosols. Personal protective equipment (PPE), including respirators, chemical-resistant gloves, and protective clothing, is mandatory for workers who may come into contact with isocyanates.

Regular air monitoring and medical surveillance programs are essential components of safety regulations in the isocyanate industry. Employers must conduct periodic air sampling to ensure that exposure levels remain below permissible limits. Additionally, workers exposed to isocyanates are required to undergo regular medical examinations to detect any early signs of health effects, particularly respiratory sensitization.

Storage and handling regulations for isocyanates are stringent due to their reactivity and potential for environmental contamination. Facilities must have proper containment systems, spill response procedures, and emergency plans in place. The transportation of isocyanates is subject to strict regulations under the Department of Transportation (DOT) guidelines, including specific packaging, labeling, and documentation requirements.

Training and education play a crucial role in ensuring compliance with safety regulations. Workers must receive comprehensive training on the hazards of isocyanates, proper handling techniques, emergency procedures, and the correct use of PPE. This training must be regularly updated to reflect any changes in regulations or best practices.

Environmental regulations also impact the isocyanate industry, with a focus on preventing releases into air, water, and soil. Facilities must comply with emissions standards set by the Environmental Protection Agency (EPA) and implement pollution control measures. Waste management and disposal of isocyanate-containing materials are subject to strict guidelines to prevent environmental contamination.

As the industry continues to evolve, safety regulations are likely to become more stringent. There is an increasing emphasis on developing safer alternatives and implementing green chemistry principles in isocyanate production and use. Companies that proactively adopt and exceed current safety standards may gain a competitive advantage in the market, as customers and regulators increasingly prioritize safety and sustainability.

One of the primary safety concerns in isocyanate handling is exposure control. Employers are required to implement engineering controls, such as closed systems and local exhaust ventilation, to minimize worker exposure to isocyanate vapors and aerosols. Personal protective equipment (PPE), including respirators, chemical-resistant gloves, and protective clothing, is mandatory for workers who may come into contact with isocyanates.

Regular air monitoring and medical surveillance programs are essential components of safety regulations in the isocyanate industry. Employers must conduct periodic air sampling to ensure that exposure levels remain below permissible limits. Additionally, workers exposed to isocyanates are required to undergo regular medical examinations to detect any early signs of health effects, particularly respiratory sensitization.

Storage and handling regulations for isocyanates are stringent due to their reactivity and potential for environmental contamination. Facilities must have proper containment systems, spill response procedures, and emergency plans in place. The transportation of isocyanates is subject to strict regulations under the Department of Transportation (DOT) guidelines, including specific packaging, labeling, and documentation requirements.

Training and education play a crucial role in ensuring compliance with safety regulations. Workers must receive comprehensive training on the hazards of isocyanates, proper handling techniques, emergency procedures, and the correct use of PPE. This training must be regularly updated to reflect any changes in regulations or best practices.

Environmental regulations also impact the isocyanate industry, with a focus on preventing releases into air, water, and soil. Facilities must comply with emissions standards set by the Environmental Protection Agency (EPA) and implement pollution control measures. Waste management and disposal of isocyanate-containing materials are subject to strict guidelines to prevent environmental contamination.

As the industry continues to evolve, safety regulations are likely to become more stringent. There is an increasing emphasis on developing safer alternatives and implementing green chemistry principles in isocyanate production and use. Companies that proactively adopt and exceed current safety standards may gain a competitive advantage in the market, as customers and regulators increasingly prioritize safety and sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!