How Isocyanates Contribute to Sustainable Growth Models?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Technology Evolution and Sustainability Goals

Isocyanates have played a pivotal role in the evolution of sustainable growth models within the chemical industry. The technology behind isocyanates has undergone significant advancements since their initial discovery in the 1930s, with a growing focus on sustainability in recent decades. This shift towards more environmentally friendly practices has been driven by increasing global awareness of climate change and the need for responsible resource management.

The development of isocyanate technology has been marked by several key milestones. Initially, the primary focus was on improving production efficiency and expanding the range of applications. However, as environmental concerns gained prominence, the industry began to explore ways to reduce the environmental impact of isocyanate production and use. This led to the development of novel synthesis methods, such as non-phosgene routes, which significantly reduced toxic byproducts and energy consumption.

In recent years, the sustainability goals for isocyanate technology have become increasingly ambitious. These objectives include reducing greenhouse gas emissions, minimizing waste generation, and improving energy efficiency throughout the production process. Additionally, there has been a concerted effort to develop bio-based isocyanates, which utilize renewable feedstocks instead of fossil fuel-derived raw materials. This approach not only reduces the carbon footprint of isocyanate production but also contributes to the circular economy by utilizing waste biomass.

Another important aspect of the sustainability drive in isocyanate technology is the focus on product lifecycle management. This involves designing products that are not only efficient in their use but also easily recyclable or biodegradable at the end of their life. For instance, research is ongoing to develop isocyanate-based polymers that can be chemically recycled, allowing for the recovery and reuse of raw materials.

The industry has also set targets for improving worker safety and reducing environmental risks associated with isocyanate handling and use. This has led to the development of safer formulations and improved handling protocols, as well as the implementation of advanced emission control technologies in production facilities. These efforts align with broader sustainability goals and contribute to the overall improvement of the industry's environmental and social performance.

Looking ahead, the future of isocyanate technology in sustainable growth models is likely to involve further innovations in green chemistry, process intensification, and the integration of renewable energy sources in production processes. The industry is also exploring the potential of digitalization and artificial intelligence to optimize production processes, reduce waste, and improve overall sustainability performance. These advancements are expected to play a crucial role in meeting increasingly stringent environmental regulations and consumer demands for more sustainable products.

The development of isocyanate technology has been marked by several key milestones. Initially, the primary focus was on improving production efficiency and expanding the range of applications. However, as environmental concerns gained prominence, the industry began to explore ways to reduce the environmental impact of isocyanate production and use. This led to the development of novel synthesis methods, such as non-phosgene routes, which significantly reduced toxic byproducts and energy consumption.

In recent years, the sustainability goals for isocyanate technology have become increasingly ambitious. These objectives include reducing greenhouse gas emissions, minimizing waste generation, and improving energy efficiency throughout the production process. Additionally, there has been a concerted effort to develop bio-based isocyanates, which utilize renewable feedstocks instead of fossil fuel-derived raw materials. This approach not only reduces the carbon footprint of isocyanate production but also contributes to the circular economy by utilizing waste biomass.

Another important aspect of the sustainability drive in isocyanate technology is the focus on product lifecycle management. This involves designing products that are not only efficient in their use but also easily recyclable or biodegradable at the end of their life. For instance, research is ongoing to develop isocyanate-based polymers that can be chemically recycled, allowing for the recovery and reuse of raw materials.

The industry has also set targets for improving worker safety and reducing environmental risks associated with isocyanate handling and use. This has led to the development of safer formulations and improved handling protocols, as well as the implementation of advanced emission control technologies in production facilities. These efforts align with broader sustainability goals and contribute to the overall improvement of the industry's environmental and social performance.

Looking ahead, the future of isocyanate technology in sustainable growth models is likely to involve further innovations in green chemistry, process intensification, and the integration of renewable energy sources in production processes. The industry is also exploring the potential of digitalization and artificial intelligence to optimize production processes, reduce waste, and improve overall sustainability performance. These advancements are expected to play a crucial role in meeting increasingly stringent environmental regulations and consumer demands for more sustainable products.

Market Demand for Sustainable Isocyanate Products

The market demand for sustainable isocyanate products has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations across various industries. Isocyanates, traditionally known for their versatility in polyurethane production, are now being reimagined through sustainable lenses to meet the evolving needs of eco-conscious consumers and businesses.

In the construction sector, there is a significant demand for sustainable insulation materials that can improve energy efficiency in buildings. Isocyanate-based foam insulations are being developed with bio-based content and improved recyclability, addressing the market's need for greener building materials. This trend is particularly strong in regions with strict energy efficiency standards, such as the European Union and parts of North America.

The automotive industry is another key driver of sustainable isocyanate demand. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are seeking lightweight materials that maintain structural integrity. Sustainable isocyanate-based composites and coatings are gaining traction, offering durability and performance while reducing the overall environmental footprint of vehicles.

In the furniture and bedding industry, there is a growing consumer preference for products with reduced environmental impact. This has led to increased demand for sustainable isocyanate-based foams that incorporate renewable raw materials or utilize more efficient production processes. Manufacturers are responding by developing bio-based polyols for use in isocyanate reactions, creating more sustainable foam products.

The packaging industry is also contributing to the demand for sustainable isocyanate products. With the rise of e-commerce and the need for protective packaging, there is a market pull for eco-friendly foam packaging solutions. Isocyanate-based packaging materials that are biodegradable or made from recycled content are becoming increasingly popular among environmentally conscious businesses and consumers.

In the textile sector, sustainable isocyanate-based coatings and finishes are gaining attention. These products offer improved durability and performance to fabrics while reducing the use of harmful chemicals. The demand is particularly strong in the outdoor and sportswear segments, where consumers are willing to pay a premium for sustainable, high-performance products.

The medical and healthcare industries are also exploring sustainable isocyanate applications. There is a growing demand for biocompatible materials that can be used in medical devices and implants. Researchers are developing sustainable isocyanate-based polymers that offer the necessary mechanical properties while being more environmentally friendly and potentially biodegradable within the human body.

As sustainability becomes a core business strategy across industries, the demand for innovative, eco-friendly isocyanate products is expected to continue its upward trajectory. This market trend is not only reshaping product development but also driving investments in research and development to create more sustainable isocyanate chemistries and applications.

In the construction sector, there is a significant demand for sustainable insulation materials that can improve energy efficiency in buildings. Isocyanate-based foam insulations are being developed with bio-based content and improved recyclability, addressing the market's need for greener building materials. This trend is particularly strong in regions with strict energy efficiency standards, such as the European Union and parts of North America.

The automotive industry is another key driver of sustainable isocyanate demand. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, they are seeking lightweight materials that maintain structural integrity. Sustainable isocyanate-based composites and coatings are gaining traction, offering durability and performance while reducing the overall environmental footprint of vehicles.

In the furniture and bedding industry, there is a growing consumer preference for products with reduced environmental impact. This has led to increased demand for sustainable isocyanate-based foams that incorporate renewable raw materials or utilize more efficient production processes. Manufacturers are responding by developing bio-based polyols for use in isocyanate reactions, creating more sustainable foam products.

The packaging industry is also contributing to the demand for sustainable isocyanate products. With the rise of e-commerce and the need for protective packaging, there is a market pull for eco-friendly foam packaging solutions. Isocyanate-based packaging materials that are biodegradable or made from recycled content are becoming increasingly popular among environmentally conscious businesses and consumers.

In the textile sector, sustainable isocyanate-based coatings and finishes are gaining attention. These products offer improved durability and performance to fabrics while reducing the use of harmful chemicals. The demand is particularly strong in the outdoor and sportswear segments, where consumers are willing to pay a premium for sustainable, high-performance products.

The medical and healthcare industries are also exploring sustainable isocyanate applications. There is a growing demand for biocompatible materials that can be used in medical devices and implants. Researchers are developing sustainable isocyanate-based polymers that offer the necessary mechanical properties while being more environmentally friendly and potentially biodegradable within the human body.

As sustainability becomes a core business strategy across industries, the demand for innovative, eco-friendly isocyanate products is expected to continue its upward trajectory. This market trend is not only reshaping product development but also driving investments in research and development to create more sustainable isocyanate chemistries and applications.

Current Challenges in Sustainable Isocyanate Production

The production of isocyanates faces several significant challenges in terms of sustainability. One of the primary issues is the reliance on fossil fuel-based raw materials, particularly petroleum derivatives. This dependence not only contributes to the depletion of non-renewable resources but also results in a substantial carbon footprint throughout the production process.

Environmental concerns are paramount in isocyanate production. The synthesis of isocyanates often involves the use of phosgene, a highly toxic and corrosive gas. While efforts have been made to develop phosgene-free routes, these alternatives are not yet widely adopted due to economic and technical limitations. The handling and disposal of hazardous by-products and waste streams also pose significant environmental risks and require stringent safety measures.

Energy efficiency remains a critical challenge in sustainable isocyanate production. The current manufacturing processes are energy-intensive, particularly in the synthesis and purification stages. This high energy consumption not only increases production costs but also contributes to greenhouse gas emissions, further exacerbating the industry's environmental impact.

Water usage and management present another sustainability hurdle. Isocyanate production requires substantial amounts of water for cooling and cleaning processes. Efficient water recycling and treatment systems are necessary to minimize consumption and prevent contamination of local water sources.

The volatility of raw material prices, especially for petroleum-based feedstocks, poses economic challenges to sustainable production. Price fluctuations can impact the stability of production costs and, consequently, the market competitiveness of isocyanate products. This volatility also hinders long-term planning and investment in more sustainable technologies.

Regulatory compliance is becoming increasingly stringent, with growing pressure to reduce emissions and improve overall environmental performance. Meeting these evolving standards while maintaining production efficiency and product quality is a significant challenge for isocyanate manufacturers.

Lastly, the development of bio-based alternatives to traditional isocyanates is still in its infancy. While promising research is underway, scaling up these sustainable alternatives to meet industrial demand remains a significant technical and economic challenge. The transition to more sustainable production methods requires substantial investment in research and development, as well as modifications to existing manufacturing infrastructure.

Environmental concerns are paramount in isocyanate production. The synthesis of isocyanates often involves the use of phosgene, a highly toxic and corrosive gas. While efforts have been made to develop phosgene-free routes, these alternatives are not yet widely adopted due to economic and technical limitations. The handling and disposal of hazardous by-products and waste streams also pose significant environmental risks and require stringent safety measures.

Energy efficiency remains a critical challenge in sustainable isocyanate production. The current manufacturing processes are energy-intensive, particularly in the synthesis and purification stages. This high energy consumption not only increases production costs but also contributes to greenhouse gas emissions, further exacerbating the industry's environmental impact.

Water usage and management present another sustainability hurdle. Isocyanate production requires substantial amounts of water for cooling and cleaning processes. Efficient water recycling and treatment systems are necessary to minimize consumption and prevent contamination of local water sources.

The volatility of raw material prices, especially for petroleum-based feedstocks, poses economic challenges to sustainable production. Price fluctuations can impact the stability of production costs and, consequently, the market competitiveness of isocyanate products. This volatility also hinders long-term planning and investment in more sustainable technologies.

Regulatory compliance is becoming increasingly stringent, with growing pressure to reduce emissions and improve overall environmental performance. Meeting these evolving standards while maintaining production efficiency and product quality is a significant challenge for isocyanate manufacturers.

Lastly, the development of bio-based alternatives to traditional isocyanates is still in its infancy. While promising research is underway, scaling up these sustainable alternatives to meet industrial demand remains a significant technical and economic challenge. The transition to more sustainable production methods requires substantial investment in research and development, as well as modifications to existing manufacturing infrastructure.

Existing Sustainable Isocyanate Production Methods

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.

- Applications of isocyanates in polymer chemistry: Isocyanates play a crucial role in polymer chemistry, particularly in the production of polyurethanes. They are used in various applications such as coatings, adhesives, foams, and elastomers. The patents describe specific formulations and methods for utilizing isocyanates in these applications.

- Isocyanate-based coating technologies: Innovations in coating technologies using isocyanates are presented. These include developments in water-based coatings, high-performance protective coatings, and specialized coatings for various industries such as automotive and construction.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents focus on improving safety measures and handling procedures. This includes methods for reducing exposure risks, developing safer storage systems, and creating less hazardous isocyanate formulations.

- Isocyanate-free alternatives and substitutes: Research into developing isocyanate-free alternatives or substitutes is presented. This includes novel chemistries and materials that can potentially replace isocyanates in certain applications, addressing environmental and health concerns associated with isocyanate use.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and reaction modifiers

Several patents focus on the development of isocyanate-based catalysts and reaction modifiers. These compounds are used to enhance chemical reactions, improve product properties, or catalyze specific transformations in various industrial processes.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents in this category address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents explore alternatives to traditional isocyanates, aiming to develop more environmentally friendly or less hazardous options. This includes novel chemistries, bio-based substitutes, and alternative crosslinking agents for various applications.Expand Specific Solutions

Key Players in Sustainable Isocyanate Market

The isocyanates market is in a mature growth stage, characterized by steady demand and established applications across various industries. The global market size for isocyanates is projected to reach significant figures, driven by increasing use in polyurethane production for automotive, construction, and furniture sectors. Technologically, isocyanates are well-developed, with major players like Wanhua Chemical, BASF, Covestro, and Mitsui Chemicals leading innovation. These companies are focusing on sustainable isocyanate production methods and bio-based alternatives to address environmental concerns. Emerging players such as Kingfa Sci. & Tech. and Hanwha Solutions are also contributing to market competitiveness through specialized product offerings and regional expansion strategies.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has made significant strides in sustainable isocyanate production. They have developed a proprietary gas-phase process for producing MDI (methylene diphenyl diisocyanate), which reduces energy consumption by up to 35% compared to traditional methods[11]. This process also minimizes waste generation and improves product quality. Wanhua has invested in bio-based polyols for use with isocyanates, reducing the carbon footprint of their polyurethane products[12]. The company has also focused on developing isocyanate-based materials for energy-efficient buildings and lightweight automotive components, contributing to overall sustainability in these sectors[13]. Additionally, Wanhua has implemented advanced recycling technologies for polyurethane waste, addressing end-of-life concerns for isocyanate-based products and promoting a circular economy approach[14].

Strengths: Leading position in the Asian market, advanced production technologies, strong R&D capabilities. Weaknesses: Relatively newer entrant to global markets outside Asia, potential geopolitical challenges affecting international expansion.

BASF Corp.

Technical Solution: BASF has developed innovative isocyanate-based solutions for sustainable growth. Their approach includes the use of bio-based raw materials to produce isocyanates, reducing the carbon footprint. They have also implemented a novel process that utilizes carbon dioxide as a raw material in polyurethane production, effectively reducing greenhouse gas emissions[1]. BASF's isocyanate products contribute to energy efficiency in buildings through improved insulation materials, and in the automotive industry by enabling lightweight design[2]. The company has also invested in recycling technologies for polyurethane materials, addressing end-of-life concerns for isocyanate-based products[3].

Strengths: Extensive R&D capabilities, global market presence, and diverse product portfolio. Weaknesses: Dependence on petrochemical feedstocks for some products, potential regulatory challenges related to isocyanate handling.

Innovative Approaches to Green Isocyanate Synthesis

Sustainable preparation of organic amino compounds for the production of organic isocyanates

PatentWO2024017890A2

Innovation

- A process using green hydrogen and green ammonia to produce organic amino compounds, which are then used to synthesize isocyanates, incorporating renewable energy sources and reducing waste through closed-loop recycling of materials.

Isocyanate composition

PatentWO2024090855A1

Innovation

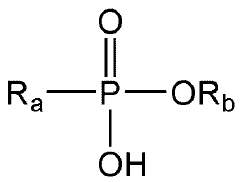

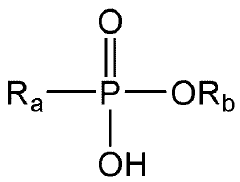

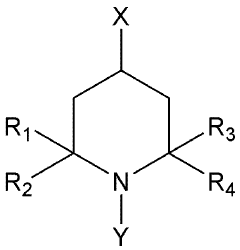

- An isocyanate composition comprising an isocyanate-based compound and a phosphonate-based compound, which slows down oligomerization and suppresses discoloration, along with a phenol-based stabilizer to prevent side reactions, improving storage stability and workability.

Environmental Impact Assessment of Isocyanates

Isocyanates, widely used in the production of polyurethanes, have significant environmental implications that require careful assessment. The environmental impact of isocyanates spans various aspects, from production to disposal, and their contribution to sustainable growth models necessitates a comprehensive evaluation.

During the production process, isocyanates can release volatile organic compounds (VOCs) and other potentially harmful emissions. These emissions may contribute to air pollution and pose risks to both human health and the environment if not properly managed. Implementing advanced emission control technologies and adhering to strict regulatory standards are crucial steps in mitigating these impacts.

Water pollution is another concern associated with isocyanate production and use. Improper handling or disposal of isocyanate-containing materials can lead to contamination of water bodies, potentially affecting aquatic ecosystems. Implementing robust wastewater treatment systems and proper disposal protocols is essential to minimize this risk and protect water resources.

The lifecycle assessment of isocyanate-based products reveals both positive and negative environmental impacts. On one hand, polyurethane products made from isocyanates often contribute to energy efficiency in buildings and vehicles, leading to reduced carbon emissions over their lifespan. On the other hand, the end-of-life disposal of these products presents challenges, as many polyurethane materials are not easily recyclable.

Biodegradability is a key consideration in the environmental impact of isocyanates. Traditional isocyanate-based materials are not readily biodegradable, which can lead to long-term environmental persistence. However, research into bio-based and more environmentally friendly alternatives is ongoing, with promising developments in creating isocyanates from renewable resources.

The carbon footprint of isocyanate production and use is a critical factor in assessing their overall environmental impact. While the production process can be energy-intensive, the application of isocyanates in energy-efficient products often results in a net positive effect on carbon emissions reduction over the product lifecycle.

Occupational and public health considerations are integral to the environmental impact assessment of isocyanates. Proper handling, storage, and application procedures are essential to prevent exposure risks and potential health hazards associated with these chemicals.

In the context of sustainable growth models, the environmental impact of isocyanates must be balanced against their economic and social benefits. Their role in creating durable, lightweight, and energy-efficient materials contributes to sustainability goals in various sectors. However, continuous improvement in production processes, product design, and end-of-life management is necessary to enhance the overall sustainability profile of isocyanate-based materials.

During the production process, isocyanates can release volatile organic compounds (VOCs) and other potentially harmful emissions. These emissions may contribute to air pollution and pose risks to both human health and the environment if not properly managed. Implementing advanced emission control technologies and adhering to strict regulatory standards are crucial steps in mitigating these impacts.

Water pollution is another concern associated with isocyanate production and use. Improper handling or disposal of isocyanate-containing materials can lead to contamination of water bodies, potentially affecting aquatic ecosystems. Implementing robust wastewater treatment systems and proper disposal protocols is essential to minimize this risk and protect water resources.

The lifecycle assessment of isocyanate-based products reveals both positive and negative environmental impacts. On one hand, polyurethane products made from isocyanates often contribute to energy efficiency in buildings and vehicles, leading to reduced carbon emissions over their lifespan. On the other hand, the end-of-life disposal of these products presents challenges, as many polyurethane materials are not easily recyclable.

Biodegradability is a key consideration in the environmental impact of isocyanates. Traditional isocyanate-based materials are not readily biodegradable, which can lead to long-term environmental persistence. However, research into bio-based and more environmentally friendly alternatives is ongoing, with promising developments in creating isocyanates from renewable resources.

The carbon footprint of isocyanate production and use is a critical factor in assessing their overall environmental impact. While the production process can be energy-intensive, the application of isocyanates in energy-efficient products often results in a net positive effect on carbon emissions reduction over the product lifecycle.

Occupational and public health considerations are integral to the environmental impact assessment of isocyanates. Proper handling, storage, and application procedures are essential to prevent exposure risks and potential health hazards associated with these chemicals.

In the context of sustainable growth models, the environmental impact of isocyanates must be balanced against their economic and social benefits. Their role in creating durable, lightweight, and energy-efficient materials contributes to sustainability goals in various sectors. However, continuous improvement in production processes, product design, and end-of-life management is necessary to enhance the overall sustainability profile of isocyanate-based materials.

Regulatory Framework for Sustainable Chemical Production

The regulatory framework for sustainable chemical production plays a crucial role in shaping the use of isocyanates in sustainable growth models. As governments and international organizations increasingly prioritize environmental protection and sustainable development, the chemical industry faces stringent regulations aimed at minimizing environmental impact and promoting responsible production practices.

At the global level, initiatives such as the United Nations' Sustainable Development Goals (SDGs) and the Paris Agreement on climate change have set the stage for more comprehensive regulatory approaches. These frameworks emphasize the need for sustainable production and consumption patterns, which directly influence the use of isocyanates in various industries.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation serves as a cornerstone for chemical management. Under REACH, manufacturers and importers of isocyanates must register their substances and provide detailed information on their properties, hazards, and safe use. This regulation has significantly impacted the isocyanate industry, driving innovation in safer alternatives and more sustainable production methods.

The United States Environmental Protection Agency (EPA) has also implemented regulations under the Toxic Substances Control Act (TSCA) that affect isocyanate production and use. These regulations focus on risk assessment, reporting requirements, and restrictions on certain chemicals, encouraging the development of more sustainable isocyanate-based products.

Many countries have adopted occupational safety and health regulations specifically addressing isocyanates due to their potential health hazards. These regulations often mandate exposure limits, personal protective equipment, and proper handling procedures, which indirectly promote the development of safer, more sustainable isocyanate formulations.

The regulatory landscape also includes voluntary industry initiatives and standards. For instance, the International Isocyanate Institute promotes responsible care practices and sustainable development within the isocyanate industry. Such self-regulatory efforts complement government regulations and help drive sustainable growth in the sector.

As the regulatory framework continues to evolve, it is pushing the isocyanate industry towards more sustainable practices. This includes the development of bio-based isocyanates, improved recycling technologies, and the implementation of circular economy principles in production processes. The regulatory pressure is thus acting as a catalyst for innovation, driving the industry to find new ways to contribute to sustainable growth models while meeting environmental and safety standards.

At the global level, initiatives such as the United Nations' Sustainable Development Goals (SDGs) and the Paris Agreement on climate change have set the stage for more comprehensive regulatory approaches. These frameworks emphasize the need for sustainable production and consumption patterns, which directly influence the use of isocyanates in various industries.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation serves as a cornerstone for chemical management. Under REACH, manufacturers and importers of isocyanates must register their substances and provide detailed information on their properties, hazards, and safe use. This regulation has significantly impacted the isocyanate industry, driving innovation in safer alternatives and more sustainable production methods.

The United States Environmental Protection Agency (EPA) has also implemented regulations under the Toxic Substances Control Act (TSCA) that affect isocyanate production and use. These regulations focus on risk assessment, reporting requirements, and restrictions on certain chemicals, encouraging the development of more sustainable isocyanate-based products.

Many countries have adopted occupational safety and health regulations specifically addressing isocyanates due to their potential health hazards. These regulations often mandate exposure limits, personal protective equipment, and proper handling procedures, which indirectly promote the development of safer, more sustainable isocyanate formulations.

The regulatory landscape also includes voluntary industry initiatives and standards. For instance, the International Isocyanate Institute promotes responsible care practices and sustainable development within the isocyanate industry. Such self-regulatory efforts complement government regulations and help drive sustainable growth in the sector.

As the regulatory framework continues to evolve, it is pushing the isocyanate industry towards more sustainable practices. This includes the development of bio-based isocyanates, improved recycling technologies, and the implementation of circular economy principles in production processes. The regulatory pressure is thus acting as a catalyst for innovation, driving the industry to find new ways to contribute to sustainable growth models while meeting environmental and safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!