Isocyanate Industry Developments in Renewable Energy

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

The isocyanate industry has undergone significant evolution in recent years, particularly in the context of renewable energy developments. This evolution can be traced through several key stages, each marked by technological advancements and shifting market demands.

In the early stages, isocyanates were primarily derived from petroleum-based feedstocks, with little consideration for renewable alternatives. The focus was on improving production efficiency and expanding applications in polyurethane foams, coatings, and adhesives. However, as environmental concerns grew and the push for sustainability intensified, the industry began to explore bio-based alternatives.

The mid-2000s saw the emergence of partial bio-based isocyanates, where a portion of the traditional petroleum-based components was replaced with renewable materials. This marked a significant shift in the industry's approach, aligning with broader sustainability goals. Companies began investing in research and development to increase the renewable content of their products while maintaining performance characteristics.

As renewable energy technologies advanced, particularly in biomass processing and fermentation, new pathways for isocyanate production emerged. The late 2010s witnessed the development of fully bio-based isocyanates, derived entirely from renewable resources such as plant oils and agricultural waste. This breakthrough represented a major milestone in the industry's evolution towards sustainability.

Concurrent with these developments, the renewable energy sector itself began to influence isocyanate production. The integration of renewable energy sources in manufacturing processes reduced the carbon footprint of isocyanate production, even for traditional petroleum-based products. Solar and wind power installations at production facilities became increasingly common, demonstrating the industry's commitment to overall sustainability.

Recent years have seen a focus on circular economy principles within the isocyanate industry. This has led to innovations in recycling and upcycling of polyurethane products, with some companies developing technologies to break down end-of-life polyurethanes and recover isocyanate precursors for reuse. This closed-loop approach represents the latest stage in the industry's evolution, combining renewable feedstocks with sustainable end-of-life solutions.

Looking forward, the isocyanate industry is poised for further evolution in the renewable energy context. Emerging technologies such as artificial photosynthesis and advanced biocatalysis hold promise for even more efficient and sustainable isocyanate production methods. As the renewable energy sector continues to grow and innovate, it is likely to drive further advancements in isocyanate technology, pushing the boundaries of what is possible in terms of sustainability and performance.

In the early stages, isocyanates were primarily derived from petroleum-based feedstocks, with little consideration for renewable alternatives. The focus was on improving production efficiency and expanding applications in polyurethane foams, coatings, and adhesives. However, as environmental concerns grew and the push for sustainability intensified, the industry began to explore bio-based alternatives.

The mid-2000s saw the emergence of partial bio-based isocyanates, where a portion of the traditional petroleum-based components was replaced with renewable materials. This marked a significant shift in the industry's approach, aligning with broader sustainability goals. Companies began investing in research and development to increase the renewable content of their products while maintaining performance characteristics.

As renewable energy technologies advanced, particularly in biomass processing and fermentation, new pathways for isocyanate production emerged. The late 2010s witnessed the development of fully bio-based isocyanates, derived entirely from renewable resources such as plant oils and agricultural waste. This breakthrough represented a major milestone in the industry's evolution towards sustainability.

Concurrent with these developments, the renewable energy sector itself began to influence isocyanate production. The integration of renewable energy sources in manufacturing processes reduced the carbon footprint of isocyanate production, even for traditional petroleum-based products. Solar and wind power installations at production facilities became increasingly common, demonstrating the industry's commitment to overall sustainability.

Recent years have seen a focus on circular economy principles within the isocyanate industry. This has led to innovations in recycling and upcycling of polyurethane products, with some companies developing technologies to break down end-of-life polyurethanes and recover isocyanate precursors for reuse. This closed-loop approach represents the latest stage in the industry's evolution, combining renewable feedstocks with sustainable end-of-life solutions.

Looking forward, the isocyanate industry is poised for further evolution in the renewable energy context. Emerging technologies such as artificial photosynthesis and advanced biocatalysis hold promise for even more efficient and sustainable isocyanate production methods. As the renewable energy sector continues to grow and innovate, it is likely to drive further advancements in isocyanate technology, pushing the boundaries of what is possible in terms of sustainability and performance.

Renewable Energy Market

The renewable energy market has experienced significant growth and transformation in recent years, driven by increasing global awareness of climate change and the need for sustainable energy sources. This market encompasses various technologies, including solar, wind, hydroelectric, geothermal, and biomass energy. The isocyanate industry, traditionally associated with fossil fuel-based products, is now exploring opportunities within this expanding renewable energy sector.

The global renewable energy market has shown robust expansion, with a compound annual growth rate (CAGR) exceeding 8% over the past decade. Solar and wind energy have been the primary drivers of this growth, accounting for the majority of new installations and investments. Governments worldwide have implemented supportive policies, such as feed-in tariffs, tax incentives, and renewable portfolio standards, to accelerate the adoption of clean energy technologies.

In the context of the isocyanate industry, the renewable energy market presents both challenges and opportunities. Isocyanates, commonly used in the production of polyurethanes, have found applications in various renewable energy technologies. For instance, polyurethane materials are utilized in wind turbine blade manufacturing, enhancing their durability and performance. Additionally, isocyanate-based insulation materials contribute to improving energy efficiency in buildings, aligning with the broader goals of the renewable energy sector.

The market demand for renewable energy solutions has led to increased research and development efforts in the isocyanate industry. Companies are exploring bio-based isocyanates derived from renewable feedstocks, aiming to reduce the carbon footprint of their products. This shift towards sustainable raw materials is driven by consumer preferences and regulatory pressures to minimize environmental impact.

The integration of isocyanates in energy storage systems, particularly in the development of advanced batteries and fuel cells, represents another promising area of growth. As renewable energy sources often require efficient storage solutions to address intermittency issues, the demand for high-performance materials in this sector is expected to rise.

However, the renewable energy market also poses challenges for the isocyanate industry. The push for circular economy principles and the need for recyclable materials have prompted research into alternative technologies that may compete with traditional isocyanate-based products. This dynamic landscape requires continuous innovation and adaptation from isocyanate manufacturers to maintain their relevance in the evolving renewable energy sector.

As the renewable energy market continues to expand, the isocyanate industry must navigate the shifting demand patterns and technological advancements. The ability to develop sustainable, high-performance materials that meet the specific requirements of renewable energy applications will be crucial for long-term success in this market.

The global renewable energy market has shown robust expansion, with a compound annual growth rate (CAGR) exceeding 8% over the past decade. Solar and wind energy have been the primary drivers of this growth, accounting for the majority of new installations and investments. Governments worldwide have implemented supportive policies, such as feed-in tariffs, tax incentives, and renewable portfolio standards, to accelerate the adoption of clean energy technologies.

In the context of the isocyanate industry, the renewable energy market presents both challenges and opportunities. Isocyanates, commonly used in the production of polyurethanes, have found applications in various renewable energy technologies. For instance, polyurethane materials are utilized in wind turbine blade manufacturing, enhancing their durability and performance. Additionally, isocyanate-based insulation materials contribute to improving energy efficiency in buildings, aligning with the broader goals of the renewable energy sector.

The market demand for renewable energy solutions has led to increased research and development efforts in the isocyanate industry. Companies are exploring bio-based isocyanates derived from renewable feedstocks, aiming to reduce the carbon footprint of their products. This shift towards sustainable raw materials is driven by consumer preferences and regulatory pressures to minimize environmental impact.

The integration of isocyanates in energy storage systems, particularly in the development of advanced batteries and fuel cells, represents another promising area of growth. As renewable energy sources often require efficient storage solutions to address intermittency issues, the demand for high-performance materials in this sector is expected to rise.

However, the renewable energy market also poses challenges for the isocyanate industry. The push for circular economy principles and the need for recyclable materials have prompted research into alternative technologies that may compete with traditional isocyanate-based products. This dynamic landscape requires continuous innovation and adaptation from isocyanate manufacturers to maintain their relevance in the evolving renewable energy sector.

As the renewable energy market continues to expand, the isocyanate industry must navigate the shifting demand patterns and technological advancements. The ability to develop sustainable, high-performance materials that meet the specific requirements of renewable energy applications will be crucial for long-term success in this market.

Technical Hurdles

The isocyanate industry's transition towards renewable energy faces several significant technical hurdles. One of the primary challenges is the development of efficient and cost-effective processes for producing bio-based isocyanates. Traditional isocyanate production relies heavily on fossil fuel-derived raw materials, making the shift to renewable sources complex and resource-intensive.

A major obstacle lies in the synthesis of bio-based polyols, which are essential precursors for isocyanate production. Current methods for converting biomass into suitable polyols often result in lower yields and inconsistent quality compared to petrochemical-based processes. This inconsistency can lead to variations in the final isocyanate products, affecting their performance and applicability in various industries.

The energy-intensive nature of isocyanate production poses another significant challenge in the context of renewable energy adoption. The high temperatures and pressures required for traditional manufacturing processes are difficult to achieve using renewable energy sources alone. Developing new catalysts and reaction pathways that can operate under milder conditions while maintaining product quality and yield is a critical area of research.

Furthermore, the storage and transportation of renewable energy-derived isocyanates present unique challenges. These compounds are highly reactive and sensitive to moisture, requiring specialized handling and storage solutions. Developing stable formulations and innovative packaging technologies that can preserve the integrity of bio-based isocyanates throughout the supply chain is crucial for their widespread adoption.

Another technical hurdle is the integration of renewable energy systems into existing isocyanate production facilities. Retrofitting plants to accommodate solar, wind, or other renewable energy sources requires significant engineering expertise and capital investment. Balancing the intermittent nature of renewable energy with the continuous production demands of the isocyanate industry remains a complex challenge.

The purification and separation of bio-based isocyanates from reaction mixtures also present technical difficulties. Traditional separation methods may not be as effective for bio-derived products, necessitating the development of novel purification techniques. These new methods must be both environmentally friendly and economically viable to align with the sustainability goals of renewable energy adoption.

Lastly, ensuring the consistent quality and performance of renewable energy-derived isocyanates compared to their fossil fuel-based counterparts is a significant hurdle. Extensive testing and validation processes are required to demonstrate that these new products meet or exceed industry standards across various applications, from polyurethane foams to coatings and adhesives.

A major obstacle lies in the synthesis of bio-based polyols, which are essential precursors for isocyanate production. Current methods for converting biomass into suitable polyols often result in lower yields and inconsistent quality compared to petrochemical-based processes. This inconsistency can lead to variations in the final isocyanate products, affecting their performance and applicability in various industries.

The energy-intensive nature of isocyanate production poses another significant challenge in the context of renewable energy adoption. The high temperatures and pressures required for traditional manufacturing processes are difficult to achieve using renewable energy sources alone. Developing new catalysts and reaction pathways that can operate under milder conditions while maintaining product quality and yield is a critical area of research.

Furthermore, the storage and transportation of renewable energy-derived isocyanates present unique challenges. These compounds are highly reactive and sensitive to moisture, requiring specialized handling and storage solutions. Developing stable formulations and innovative packaging technologies that can preserve the integrity of bio-based isocyanates throughout the supply chain is crucial for their widespread adoption.

Another technical hurdle is the integration of renewable energy systems into existing isocyanate production facilities. Retrofitting plants to accommodate solar, wind, or other renewable energy sources requires significant engineering expertise and capital investment. Balancing the intermittent nature of renewable energy with the continuous production demands of the isocyanate industry remains a complex challenge.

The purification and separation of bio-based isocyanates from reaction mixtures also present technical difficulties. Traditional separation methods may not be as effective for bio-derived products, necessitating the development of novel purification techniques. These new methods must be both environmentally friendly and economically viable to align with the sustainability goals of renewable energy adoption.

Lastly, ensuring the consistent quality and performance of renewable energy-derived isocyanates compared to their fossil fuel-based counterparts is a significant hurdle. Extensive testing and validation processes are required to demonstrate that these new products meet or exceed industry standards across various applications, from polyurethane foams to coatings and adhesives.

Current Solutions

01 Synthesis and properties of isocyanates

Isocyanates are a class of highly reactive compounds characterized by the -N=C=O functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl-containing compounds. Their properties, such as reactivity and stability, are crucial for various industrial applications.- Synthesis and applications of isocyanates: Isocyanates are versatile compounds used in various industrial applications. They are key ingredients in the production of polyurethanes, coatings, adhesives, and elastomers. The synthesis of isocyanates often involves the reaction of amines with phosgene or alternative routes to avoid the use of toxic phosgene.

- Isocyanate-based polymer formulations: Isocyanates are crucial in polymer chemistry, particularly in the development of polyurethanes. These formulations often include polyols, catalysts, and additives to control properties such as flexibility, durability, and chemical resistance. The ratio of isocyanate to polyol and the selection of specific isocyanate types greatly influence the final polymer characteristics.

- Isocyanate modifications and derivatives: Chemical modifications of isocyanates can lead to improved properties or new functionalities. This includes the development of blocked isocyanates for controlled reactivity, isocyanate-terminated prepolymers for specific applications, and the synthesis of novel isocyanate derivatives with enhanced performance characteristics.

- Environmental and safety considerations in isocyanate handling: Due to the reactivity and potential health hazards of isocyanates, significant emphasis is placed on safe handling, storage, and disposal practices. This includes the development of low-emission isocyanate systems, personal protective equipment protocols, and environmental impact assessments for isocyanate-based products and processes.

- Isocyanate-free alternatives and sustainable technologies: Research into isocyanate-free alternatives is driven by environmental and health concerns. This includes the development of bio-based isocyanates, non-isocyanate polyurethanes (NIPUs), and alternative crosslinking chemistries that can provide similar performance to traditional isocyanate-based systems while reducing environmental impact.

02 Applications of isocyanates in coatings and adhesives

Isocyanates play a significant role in the formulation of high-performance coatings and adhesives. They react with polyols to form polyurethanes, which offer excellent durability, chemical resistance, and adhesion properties. These materials find applications in automotive coatings, industrial finishes, and structural adhesives. The choice of isocyanate and its formulation can be tailored to achieve specific performance characteristics.Expand Specific Solutions03 Isocyanate-based foam technologies

Isocyanates are crucial components in the production of polyurethane foams. These foams are used in various applications, including insulation, cushioning, and packaging. The reaction between isocyanates and polyols, combined with blowing agents, creates the cellular structure of the foam. Different types of isocyanates and formulation techniques can be employed to achieve specific foam properties, such as density, rigidity, and thermal insulation.Expand Specific Solutions04 Safety and handling of isocyanates

Due to their high reactivity, isocyanates require careful handling and safety precautions. Exposure to isocyanates can cause respiratory irritation and sensitization. Proper personal protective equipment, ventilation systems, and handling procedures are essential in industrial settings. Additionally, the development of low-emission or blocked isocyanates has been a focus to improve safety and reduce environmental impact in various applications.Expand Specific Solutions05 Novel isocyanate chemistries and modifications

Research in isocyanate chemistry continues to yield novel compounds and modifications. This includes the development of bio-based isocyanates, isocyanate-free alternatives, and modified isocyanates with enhanced properties. These innovations aim to improve performance, reduce environmental impact, and expand the application range of isocyanate-based materials in industries such as construction, automotive, and electronics.Expand Specific Solutions

Industry Leaders

The isocyanate industry in renewable energy is in a transitional phase, with growing market potential as sustainability concerns drive innovation. The global market size is expanding, projected to reach several billion dollars by 2030. Technologically, the field is advancing rapidly, with key players like Wanhua Chemical, Covestro, and Mitsui Chemicals leading research into bio-based isocyanates and renewable polyurethane applications. Companies such as BASF and Evonik are also making significant strides in developing more sustainable isocyanate products. While traditional petrochemical-based isocyanates still dominate, there's increasing focus on eco-friendly alternatives, indicating a shift towards maturity in renewable energy applications.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed bio-based isocyanates derived from renewable resources, focusing on sustainable polyurethane production. Their technology utilizes plant-based feedstocks to create isocyanates with properties comparable to petroleum-based counterparts. The company has invested in large-scale production facilities capable of manufacturing these bio-based isocyanates, with an annual capacity reaching 100,000 tons[1]. Wanhua's process involves the conversion of biomass into diamine intermediates, which are then transformed into isocyanates through phosgene-free methods, reducing environmental impact[2]. This approach aligns with the growing demand for eco-friendly materials in various industries, including construction, automotive, and consumer goods.

Strengths: Reduced carbon footprint, alignment with sustainability goals, and potential for cost-effective production as renewable feedstock technologies mature. Weaknesses: Initial higher production costs compared to traditional petrochemical routes and potential limitations in feedstock availability.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered the development of CO2-based polyols for use in isocyanate reactions, effectively reducing the reliance on fossil fuels in polyurethane production. Their innovative cardyon® technology incorporates up to 20% CO2 as a raw material, replacing a portion of the petroleum-based feedstock[3]. This process not only utilizes waste CO2 but also decreases the carbon footprint of the final products. Covestro has successfully scaled up this technology, operating a production plant with an annual capacity of 5,000 metric tons of CO2-based polyols[4]. The company has also explored the application of this technology in various sectors, including mattresses, sports flooring, and automotive interiors, demonstrating the versatility of their renewable energy-driven isocyanate developments.

Strengths: Direct utilization of waste CO2, reducing greenhouse gas emissions and fossil fuel dependency. Weaknesses: Limited CO2 incorporation percentage and the need for further research to increase the proportion of CO2-based content in final products.

Key Innovations

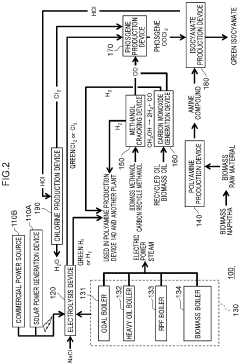

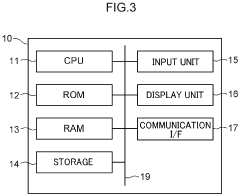

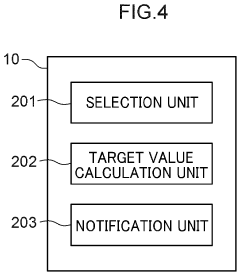

Isocyanate production system, isocyanate composition, polymerizable composition, resin, and molded article

PatentPendingEP4371974A1

Innovation

- An isocyanate production system that utilizes biomass-based energy sources, recycled materials, and carbon monoxide and hydrogen generated from renewable sources to produce phosgene and polyamine compounds, with a control device optimizing energy and material usage to minimize environmental load and carbon dioxide emissions.

Sustainable preparation of hexamethylene diisocyanate for the production of polyurethane

PatentWO2024208940A2

Innovation

- A sustainable production process for hexamethylene diisocyanate using renewable raw materials and renewable energy sources, involving steps such as the partial reduction of CO2 to CO, partial oxidation of organic materials, and electrolysis to produce methanol and ammonia, followed by catalytic conversions to form hexamethylene diisocyanate, reducing energy consumption and emissions.

Environmental Impact

The isocyanate industry's shift towards renewable energy sources has significant environmental implications. As the sector explores sustainable alternatives to traditional fossil fuel-based processes, the environmental impact of isocyanate production is undergoing notable changes.

One of the primary environmental benefits of incorporating renewable energy into isocyanate manufacturing is the reduction of greenhouse gas emissions. Traditional production methods rely heavily on fossil fuels, contributing to carbon dioxide and other harmful emissions. By transitioning to renewable energy sources such as solar, wind, or biomass, the industry can substantially decrease its carbon footprint and mitigate its impact on climate change.

Water consumption and pollution are also critical environmental concerns in isocyanate production. Renewable energy integration can lead to more efficient water use and treatment processes. For instance, solar-powered water purification systems can reduce the need for chemical treatments, minimizing the release of pollutants into water bodies.

The adoption of renewable energy in isocyanate manufacturing can also contribute to improved air quality. Conventional production methods often release volatile organic compounds (VOCs) and other air pollutants. Renewable energy technologies, coupled with advanced emission control systems, can significantly reduce these harmful emissions, leading to better air quality in surrounding communities.

Land use and biodiversity impacts are additional factors to consider. While renewable energy installations may require land area, careful planning and site selection can minimize habitat disruption. Moreover, the reduced need for fossil fuel extraction and transportation can help preserve natural ecosystems and protect biodiversity.

Waste management is another area where renewable energy integration can yield environmental benefits. Energy-efficient processes powered by renewable sources can optimize material use and reduce waste generation. Additionally, the implementation of circular economy principles in conjunction with renewable energy can further minimize the environmental footprint of isocyanate production.

The transition to renewable energy in the isocyanate industry also presents opportunities for developing more environmentally friendly products. Bio-based isocyanates and other sustainable alternatives can be more easily produced using renewable energy, potentially reducing the overall environmental impact throughout the product lifecycle.

However, it is important to note that the environmental benefits of renewable energy integration must be balanced against potential challenges. These may include the environmental impacts associated with the production and disposal of renewable energy technologies, such as solar panels or wind turbines. A comprehensive life cycle assessment is crucial to ensure that the shift towards renewable energy truly results in net positive environmental outcomes for the isocyanate industry.

One of the primary environmental benefits of incorporating renewable energy into isocyanate manufacturing is the reduction of greenhouse gas emissions. Traditional production methods rely heavily on fossil fuels, contributing to carbon dioxide and other harmful emissions. By transitioning to renewable energy sources such as solar, wind, or biomass, the industry can substantially decrease its carbon footprint and mitigate its impact on climate change.

Water consumption and pollution are also critical environmental concerns in isocyanate production. Renewable energy integration can lead to more efficient water use and treatment processes. For instance, solar-powered water purification systems can reduce the need for chemical treatments, minimizing the release of pollutants into water bodies.

The adoption of renewable energy in isocyanate manufacturing can also contribute to improved air quality. Conventional production methods often release volatile organic compounds (VOCs) and other air pollutants. Renewable energy technologies, coupled with advanced emission control systems, can significantly reduce these harmful emissions, leading to better air quality in surrounding communities.

Land use and biodiversity impacts are additional factors to consider. While renewable energy installations may require land area, careful planning and site selection can minimize habitat disruption. Moreover, the reduced need for fossil fuel extraction and transportation can help preserve natural ecosystems and protect biodiversity.

Waste management is another area where renewable energy integration can yield environmental benefits. Energy-efficient processes powered by renewable sources can optimize material use and reduce waste generation. Additionally, the implementation of circular economy principles in conjunction with renewable energy can further minimize the environmental footprint of isocyanate production.

The transition to renewable energy in the isocyanate industry also presents opportunities for developing more environmentally friendly products. Bio-based isocyanates and other sustainable alternatives can be more easily produced using renewable energy, potentially reducing the overall environmental impact throughout the product lifecycle.

However, it is important to note that the environmental benefits of renewable energy integration must be balanced against potential challenges. These may include the environmental impacts associated with the production and disposal of renewable energy technologies, such as solar panels or wind turbines. A comprehensive life cycle assessment is crucial to ensure that the shift towards renewable energy truly results in net positive environmental outcomes for the isocyanate industry.

Policy Implications

The development of renewable energy in the isocyanate industry has significant policy implications that require careful consideration and strategic planning. Governments and regulatory bodies play a crucial role in shaping the industry's transition towards more sustainable practices.

One key policy area is the implementation of incentives and subsidies to encourage the adoption of renewable energy sources in isocyanate production. This may include tax credits, grants, or preferential loan terms for companies investing in renewable energy infrastructure. Such policies can help offset the initial capital costs associated with transitioning to cleaner energy sources, making it more economically viable for businesses to embrace sustainable practices.

Environmental regulations also play a vital role in driving the shift towards renewable energy in the isocyanate industry. Stricter emissions standards and carbon pricing mechanisms can create a strong incentive for companies to reduce their reliance on fossil fuels and explore cleaner alternatives. Policymakers must strike a balance between setting ambitious targets and providing a realistic timeline for industry adaptation to avoid undue economic strain.

Research and development support is another critical policy area. Governments can allocate funding for academic institutions and private sector collaborations to accelerate innovation in renewable energy technologies specific to the isocyanate industry. This may include developing more efficient processes for bio-based isocyanate production or improving the integration of renewable energy sources into existing manufacturing facilities.

Trade policies and international cooperation also have significant implications for the industry's renewable energy transition. Harmonizing standards and regulations across borders can facilitate the global adoption of sustainable practices and create a level playing field for companies operating in different regions. Additionally, policies promoting technology transfer and knowledge sharing between developed and developing countries can help accelerate the worldwide transition to renewable energy in isocyanate production.

Workforce development policies are essential to ensure a smooth transition to renewable energy in the isocyanate industry. Governments and industry stakeholders should collaborate on training programs and educational initiatives to equip workers with the skills needed to operate and maintain renewable energy systems in isocyanate production facilities. This proactive approach can help address potential job displacement concerns and create new employment opportunities in the green energy sector.

Lastly, policies addressing the entire lifecycle of isocyanate products are crucial. This includes regulations on recycling, waste management, and the promotion of circular economy principles. By implementing comprehensive policies that consider the environmental impact of isocyanates from production to disposal, policymakers can drive holistic sustainability improvements across the industry.

One key policy area is the implementation of incentives and subsidies to encourage the adoption of renewable energy sources in isocyanate production. This may include tax credits, grants, or preferential loan terms for companies investing in renewable energy infrastructure. Such policies can help offset the initial capital costs associated with transitioning to cleaner energy sources, making it more economically viable for businesses to embrace sustainable practices.

Environmental regulations also play a vital role in driving the shift towards renewable energy in the isocyanate industry. Stricter emissions standards and carbon pricing mechanisms can create a strong incentive for companies to reduce their reliance on fossil fuels and explore cleaner alternatives. Policymakers must strike a balance between setting ambitious targets and providing a realistic timeline for industry adaptation to avoid undue economic strain.

Research and development support is another critical policy area. Governments can allocate funding for academic institutions and private sector collaborations to accelerate innovation in renewable energy technologies specific to the isocyanate industry. This may include developing more efficient processes for bio-based isocyanate production or improving the integration of renewable energy sources into existing manufacturing facilities.

Trade policies and international cooperation also have significant implications for the industry's renewable energy transition. Harmonizing standards and regulations across borders can facilitate the global adoption of sustainable practices and create a level playing field for companies operating in different regions. Additionally, policies promoting technology transfer and knowledge sharing between developed and developing countries can help accelerate the worldwide transition to renewable energy in isocyanate production.

Workforce development policies are essential to ensure a smooth transition to renewable energy in the isocyanate industry. Governments and industry stakeholders should collaborate on training programs and educational initiatives to equip workers with the skills needed to operate and maintain renewable energy systems in isocyanate production facilities. This proactive approach can help address potential job displacement concerns and create new employment opportunities in the green energy sector.

Lastly, policies addressing the entire lifecycle of isocyanate products are crucial. This includes regulations on recycling, waste management, and the promotion of circular economy principles. By implementing comprehensive policies that consider the environmental impact of isocyanates from production to disposal, policymakers can drive holistic sustainability improvements across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!