Isocyanate Transformations: Powering Low-Emission Solutions

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Chemistry Evolution and Objectives

Isocyanate chemistry has undergone significant evolution since its inception in the early 20th century. Initially discovered by Adolph Wurtz in 1848, isocyanates gained prominence in the 1930s with Otto Bayer's groundbreaking work on polyurethane synthesis. This marked the beginning of a new era in polymer science and industrial applications.

The development of isocyanate chemistry has been driven by the increasing demand for versatile and high-performance materials across various sectors. From automotive and construction to furniture and electronics, isocyanates have become integral components in numerous products. The evolution of this field has been characterized by continuous improvements in synthesis methods, reactivity control, and the exploration of novel applications.

In recent decades, the focus of isocyanate chemistry has shifted towards addressing environmental concerns and sustainability issues. This paradigm shift has led to the exploration of bio-based isocyanates, non-toxic alternatives, and more efficient production processes. The industry has been actively seeking ways to reduce volatile organic compound (VOC) emissions and minimize the environmental impact of isocyanate-based products.

The primary objective in the field of isocyanate transformations is to develop low-emission solutions that maintain or enhance the desirable properties of traditional isocyanate-based materials. This goal aligns with global efforts to combat climate change and reduce the carbon footprint of industrial processes. Researchers and industry professionals are working towards creating isocyanate derivatives that offer improved safety profiles, reduced environmental impact, and enhanced performance characteristics.

Another key objective is to expand the application scope of isocyanate chemistry. This includes exploring new reaction pathways, developing novel catalysts, and investigating unconventional isocyanate precursors. The aim is to unlock new possibilities in material science, potentially leading to breakthroughs in areas such as energy storage, advanced coatings, and biomedical applications.

As we look to the future, the evolution of isocyanate chemistry is expected to continue its trajectory towards more sustainable and efficient solutions. The integration of green chemistry principles, the adoption of renewable feedstocks, and the development of circular economy approaches are likely to shape the next generation of isocyanate transformations. These advancements will play a crucial role in powering low-emission solutions across various industries, contributing to a more sustainable and environmentally friendly future.

The development of isocyanate chemistry has been driven by the increasing demand for versatile and high-performance materials across various sectors. From automotive and construction to furniture and electronics, isocyanates have become integral components in numerous products. The evolution of this field has been characterized by continuous improvements in synthesis methods, reactivity control, and the exploration of novel applications.

In recent decades, the focus of isocyanate chemistry has shifted towards addressing environmental concerns and sustainability issues. This paradigm shift has led to the exploration of bio-based isocyanates, non-toxic alternatives, and more efficient production processes. The industry has been actively seeking ways to reduce volatile organic compound (VOC) emissions and minimize the environmental impact of isocyanate-based products.

The primary objective in the field of isocyanate transformations is to develop low-emission solutions that maintain or enhance the desirable properties of traditional isocyanate-based materials. This goal aligns with global efforts to combat climate change and reduce the carbon footprint of industrial processes. Researchers and industry professionals are working towards creating isocyanate derivatives that offer improved safety profiles, reduced environmental impact, and enhanced performance characteristics.

Another key objective is to expand the application scope of isocyanate chemistry. This includes exploring new reaction pathways, developing novel catalysts, and investigating unconventional isocyanate precursors. The aim is to unlock new possibilities in material science, potentially leading to breakthroughs in areas such as energy storage, advanced coatings, and biomedical applications.

As we look to the future, the evolution of isocyanate chemistry is expected to continue its trajectory towards more sustainable and efficient solutions. The integration of green chemistry principles, the adoption of renewable feedstocks, and the development of circular economy approaches are likely to shape the next generation of isocyanate transformations. These advancements will play a crucial role in powering low-emission solutions across various industries, contributing to a more sustainable and environmentally friendly future.

Market Demand for Low-Emission Products

The market demand for low-emission products has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations aimed at reducing greenhouse gas emissions. This trend is particularly evident in industries such as automotive, construction, and consumer goods, where isocyanate-based products play a significant role.

In the automotive sector, there is a strong push for lightweight materials that can improve fuel efficiency and reduce emissions. Low-emission polyurethane foams and coatings derived from isocyanate transformations are gaining traction as they offer excellent insulation properties and durability while minimizing environmental impact. Major automakers are increasingly incorporating these materials into their vehicle designs to meet both consumer preferences and regulatory requirements.

The construction industry is another key market for low-emission products. As green building standards become more prevalent, there is a growing demand for sustainable insulation materials and adhesives. Isocyanate-based products that offer improved energy efficiency and reduced volatile organic compound (VOC) emissions are seeing increased adoption in both residential and commercial construction projects.

Consumer goods manufacturers are also responding to the market demand for eco-friendly products. From furniture to footwear, companies are exploring low-emission alternatives to traditional materials. Isocyanate-derived products that offer comparable performance with reduced environmental impact are becoming increasingly popular among environmentally conscious consumers.

The healthcare sector presents another significant market opportunity for low-emission isocyanate-based products. Medical devices, equipment, and facilities require materials that meet strict hygiene standards while minimizing potential health risks associated with emissions. This has led to increased interest in developing low-emission polyurethanes for medical applications.

Geographically, the demand for low-emission products is particularly strong in regions with stringent environmental regulations, such as the European Union, North America, and parts of Asia. These markets are driving innovation in isocyanate transformations to meet both regulatory requirements and consumer expectations.

The market size for low-emission products derived from isocyanate transformations is projected to grow significantly in the coming years. This growth is fueled by a combination of regulatory pressures, corporate sustainability initiatives, and changing consumer preferences. As industries continue to prioritize sustainability and environmental responsibility, the demand for innovative, low-emission solutions is expected to accelerate, creating new opportunities for companies investing in isocyanate transformation technologies.

In the automotive sector, there is a strong push for lightweight materials that can improve fuel efficiency and reduce emissions. Low-emission polyurethane foams and coatings derived from isocyanate transformations are gaining traction as they offer excellent insulation properties and durability while minimizing environmental impact. Major automakers are increasingly incorporating these materials into their vehicle designs to meet both consumer preferences and regulatory requirements.

The construction industry is another key market for low-emission products. As green building standards become more prevalent, there is a growing demand for sustainable insulation materials and adhesives. Isocyanate-based products that offer improved energy efficiency and reduced volatile organic compound (VOC) emissions are seeing increased adoption in both residential and commercial construction projects.

Consumer goods manufacturers are also responding to the market demand for eco-friendly products. From furniture to footwear, companies are exploring low-emission alternatives to traditional materials. Isocyanate-derived products that offer comparable performance with reduced environmental impact are becoming increasingly popular among environmentally conscious consumers.

The healthcare sector presents another significant market opportunity for low-emission isocyanate-based products. Medical devices, equipment, and facilities require materials that meet strict hygiene standards while minimizing potential health risks associated with emissions. This has led to increased interest in developing low-emission polyurethanes for medical applications.

Geographically, the demand for low-emission products is particularly strong in regions with stringent environmental regulations, such as the European Union, North America, and parts of Asia. These markets are driving innovation in isocyanate transformations to meet both regulatory requirements and consumer expectations.

The market size for low-emission products derived from isocyanate transformations is projected to grow significantly in the coming years. This growth is fueled by a combination of regulatory pressures, corporate sustainability initiatives, and changing consumer preferences. As industries continue to prioritize sustainability and environmental responsibility, the demand for innovative, low-emission solutions is expected to accelerate, creating new opportunities for companies investing in isocyanate transformation technologies.

Current Challenges in Isocyanate Transformations

Isocyanate transformations, while promising for low-emission solutions, face several significant challenges in their current state of development and application. One of the primary obstacles is the high reactivity of isocyanates, which makes them difficult to control and manipulate in industrial processes. This reactivity often leads to unwanted side reactions, reducing the efficiency and selectivity of desired transformations.

The toxicity of isocyanates presents another major challenge, particularly in terms of worker safety and environmental impact. Many isocyanates are known respiratory irritants and potential carcinogens, necessitating stringent safety protocols and protective measures in their handling and use. This not only increases production costs but also limits the widespread adoption of isocyanate-based technologies in certain industries.

Energy consumption in isocyanate transformations remains a significant concern. Many current processes require high temperatures or pressures, contributing to increased carbon footprints and operational costs. This energy intensity contradicts the goal of developing truly low-emission solutions, creating a paradox that researchers and industry professionals are striving to resolve.

The dependence on fossil fuel-derived raw materials for isocyanate production is another critical challenge. As the world moves towards more sustainable practices, finding renewable sources for isocyanate precursors becomes increasingly important. However, developing economically viable and scalable bio-based alternatives has proven to be a complex task, with many proposed solutions still in early research stages.

Catalyst development for isocyanate transformations presents its own set of challenges. While catalysts can significantly improve reaction efficiency and selectivity, finding catalysts that are both highly effective and economically feasible for large-scale production remains an ongoing struggle. Many promising catalytic systems suffer from issues such as high cost, limited availability, or poor recyclability.

Scaling up laboratory-proven isocyanate transformations to industrial levels introduces additional complexities. Issues such as heat transfer, mixing efficiency, and reaction kinetics can behave differently at larger scales, often requiring significant process re-engineering and optimization. This scaling challenge can lead to delays in commercialization and increased development costs.

Regulatory hurdles and evolving environmental standards also pose significant challenges to the advancement of isocyanate transformations. As emission regulations become more stringent globally, technologies must continuously adapt to meet new requirements, sometimes necessitating complete overhauls of established processes.

The toxicity of isocyanates presents another major challenge, particularly in terms of worker safety and environmental impact. Many isocyanates are known respiratory irritants and potential carcinogens, necessitating stringent safety protocols and protective measures in their handling and use. This not only increases production costs but also limits the widespread adoption of isocyanate-based technologies in certain industries.

Energy consumption in isocyanate transformations remains a significant concern. Many current processes require high temperatures or pressures, contributing to increased carbon footprints and operational costs. This energy intensity contradicts the goal of developing truly low-emission solutions, creating a paradox that researchers and industry professionals are striving to resolve.

The dependence on fossil fuel-derived raw materials for isocyanate production is another critical challenge. As the world moves towards more sustainable practices, finding renewable sources for isocyanate precursors becomes increasingly important. However, developing economically viable and scalable bio-based alternatives has proven to be a complex task, with many proposed solutions still in early research stages.

Catalyst development for isocyanate transformations presents its own set of challenges. While catalysts can significantly improve reaction efficiency and selectivity, finding catalysts that are both highly effective and economically feasible for large-scale production remains an ongoing struggle. Many promising catalytic systems suffer from issues such as high cost, limited availability, or poor recyclability.

Scaling up laboratory-proven isocyanate transformations to industrial levels introduces additional complexities. Issues such as heat transfer, mixing efficiency, and reaction kinetics can behave differently at larger scales, often requiring significant process re-engineering and optimization. This scaling challenge can lead to delays in commercialization and increased development costs.

Regulatory hurdles and evolving environmental standards also pose significant challenges to the advancement of isocyanate transformations. As emission regulations become more stringent globally, technologies must continuously adapt to meet new requirements, sometimes necessitating complete overhauls of established processes.

Existing Low-Emission Isocyanate Solutions

01 Reduction of isocyanate emissions in manufacturing processes

Various methods and technologies are employed to reduce isocyanate emissions during manufacturing processes. These may include improved ventilation systems, process optimization, and the use of alternative materials or formulations that produce fewer emissions. Such approaches aim to minimize worker exposure and environmental impact.- Reduction of isocyanate emissions in manufacturing processes: Various methods and technologies are employed to reduce isocyanate emissions during manufacturing processes. These may include improved ventilation systems, process optimization, and the use of specialized equipment to capture and treat emissions. Such approaches aim to minimize worker exposure and environmental impact.

- Development of low-emission isocyanate formulations: Research focuses on developing isocyanate formulations with reduced emission profiles. This involves modifying the chemical structure of isocyanates or incorporating additives that suppress volatility. These formulations aim to maintain performance while reducing potential health and environmental risks.

- Monitoring and detection of isocyanate emissions: Advanced monitoring and detection systems are crucial for managing isocyanate emissions. These may include real-time sensors, spectroscopic techniques, and analytical methods for quantifying isocyanate levels in air or other media. Accurate detection helps in implementing timely control measures and ensuring regulatory compliance.

- Isocyanate emission control in spray applications: Specific techniques are developed for controlling isocyanate emissions in spray applications, such as in painting or foam insulation. These may include improved spray gun designs, enclosure systems, and the use of alternative application methods to minimize overspray and aerosol formation.

- Treatment and disposal of isocyanate-containing waste: Proper treatment and disposal of isocyanate-containing waste are essential for minimizing emissions. This includes developing methods for neutralizing or degrading isocyanates in waste streams, as well as designing safe disposal protocols for contaminated materials and equipment.

02 Detection and monitoring of isocyanate emissions

Advanced detection and monitoring systems are developed to accurately measure and track isocyanate emissions in real-time. These systems may utilize spectroscopic techniques, chemical sensors, or other analytical methods to provide continuous monitoring and early warning of potential exposure risks.Expand Specific Solutions03 Personal protective equipment for isocyanate exposure

Specialized personal protective equipment (PPE) is designed to protect workers from isocyanate exposure. This may include respirators with specific filters, protective clothing, and gloves that are resistant to isocyanate penetration. Proper selection, use, and maintenance of PPE are crucial for worker safety.Expand Specific Solutions04 Isocyanate-free or low-emission alternatives

Research and development efforts focus on creating isocyanate-free or low-emission alternatives for various applications. These may include new polymer formulations, alternative curing systems, or entirely different material technologies that can replace traditional isocyanate-based products while maintaining desired performance characteristics.Expand Specific Solutions05 Emission control in spray applications

Specific techniques and equipment are developed to control isocyanate emissions during spray applications, such as in painting or foam insulation. These may include improved spray gun designs, containment systems, and application methods that minimize overspray and aerosol formation, thereby reducing potential exposure and environmental release.Expand Specific Solutions

Key Industry Players and Competitors

The isocyanate transformations market for low-emission solutions is in a growth phase, driven by increasing environmental regulations and demand for sustainable products. The market size is expanding rapidly, with major players like Mitsui Chemicals, Wanhua Chemical, and Bayer AG investing heavily in research and development. Technological maturity varies, with established companies like BASF and Covestro leading in innovation, while newer entrants like Wanhua Chemical (Ningbo) are quickly catching up. The competitive landscape is characterized by a mix of global chemical giants and specialized firms, with a focus on developing more efficient and environmentally friendly isocyanate-based products for various industries.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed innovative approaches to isocyanate transformations for low-emission solutions. Their strategy includes the development of novel catalysts that enable more efficient and selective isocyanate reactions, reducing waste and emissions[12]. Mitsui has also invested in the production of bio-based isocyanates, utilizing plant-derived raw materials to reduce the carbon footprint of their products[13]. Additionally, they have implemented advanced process technologies that minimize the release of volatile organic compounds (VOCs) during isocyanate production and application. Mitsui's commitment to sustainability is further demonstrated by their research into non-isocyanate polyurethanes (NIPUs) as alternative low-emission materials[14].

Strengths: Advanced catalyst technology, bio-based isocyanates, and research into non-isocyanate alternatives. Weaknesses: Potential challenges in maintaining product performance across all applications with new technologies.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed innovative isocyanate transformation technologies for low-emission solutions. Their approach focuses on the catalytic conversion of isocyanates to form more environmentally friendly products. They have implemented a novel process that utilizes metal-organic frameworks (MOFs) as catalysts to facilitate the transformation of isocyanates into cyclic carbonates and other value-added chemicals[1]. This method significantly reduces harmful emissions associated with traditional isocyanate production. Additionally, Wanhua has invested in green chemistry principles, incorporating bio-based raw materials in their isocyanate transformations, which further reduces the carbon footprint of their products[2].

Strengths: Advanced catalytic technology, reduced emissions, and integration of bio-based materials. Weaknesses: Potential high costs associated with new technology implementation and scaling up production.

Innovative Approaches in Isocyanate Chemistry

Modified isocyanates

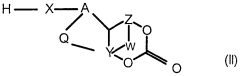

PatentWO2000020477A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable and reacts only under specific conditions, allowing for controlled crosslinking reactions without releasing isocyanate functions prematurely, using cyclic carbonates to form stable polyisocyanates that can react with nucleophilic compounds to create coatings and foams.

Modified isocyanates

PatentInactiveEP1129120A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable and only reacts under appropriate conditions, allowing for crosslinking reactions without the drawbacks of free isocyanate groups, such as those formed by reacting polyisocyanates with cyclic carbonates, resulting in stable polyisocyanates that can form coatings and polymers without expansion, and can be used in industrial structures like paints or varnishes.

Environmental Regulations Impact

Environmental regulations have become increasingly stringent in recent years, significantly impacting the isocyanate industry and driving the development of low-emission solutions. These regulations aim to reduce harmful emissions and protect both human health and the environment, forcing manufacturers to adapt their processes and products.

One of the primary drivers of change has been the implementation of volatile organic compound (VOC) emission limits. Isocyanates, being reactive compounds, can contribute to VOC emissions during production and application processes. As a result, manufacturers have been compelled to develop innovative formulations and application techniques that minimize VOC release.

The automotive industry, a major consumer of isocyanate-based products, has been particularly affected by these regulations. Stringent emission standards for vehicles have led to increased demand for lightweight materials and low-emission coatings. This has spurred research into isocyanate-based materials that can contribute to weight reduction while maintaining or improving performance characteristics.

In the construction sector, regulations targeting indoor air quality have also influenced isocyanate use. Concerns over off-gassing from building materials have led to the development of low-emission polyurethane foams and adhesives. Manufacturers have responded by creating products with reduced isocyanate content or exploring alternative chemistries that maintain desired performance properties.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has had a significant impact on the isocyanate industry. It requires manufacturers to provide detailed information on the properties and potential risks of chemicals, including isocyanates. This has led to increased transparency and safety measures in the production and use of these compounds.

In response to these regulatory pressures, the industry has invested heavily in research and development of low-emission isocyanate technologies. This includes the exploration of water-based systems, high-solids formulations, and novel curing mechanisms that reduce or eliminate volatile emissions. Additionally, there has been a growing interest in bio-based isocyanates derived from renewable resources, aligning with broader sustainability goals.

The impact of environmental regulations has extended beyond product formulations to manufacturing processes. Companies have implemented improved emission control technologies and adopted more efficient production methods to reduce their environmental footprint. This has led to the development of closed-loop systems and advanced filtration technologies that minimize the release of isocyanates and related compounds into the environment.

One of the primary drivers of change has been the implementation of volatile organic compound (VOC) emission limits. Isocyanates, being reactive compounds, can contribute to VOC emissions during production and application processes. As a result, manufacturers have been compelled to develop innovative formulations and application techniques that minimize VOC release.

The automotive industry, a major consumer of isocyanate-based products, has been particularly affected by these regulations. Stringent emission standards for vehicles have led to increased demand for lightweight materials and low-emission coatings. This has spurred research into isocyanate-based materials that can contribute to weight reduction while maintaining or improving performance characteristics.

In the construction sector, regulations targeting indoor air quality have also influenced isocyanate use. Concerns over off-gassing from building materials have led to the development of low-emission polyurethane foams and adhesives. Manufacturers have responded by creating products with reduced isocyanate content or exploring alternative chemistries that maintain desired performance properties.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has had a significant impact on the isocyanate industry. It requires manufacturers to provide detailed information on the properties and potential risks of chemicals, including isocyanates. This has led to increased transparency and safety measures in the production and use of these compounds.

In response to these regulatory pressures, the industry has invested heavily in research and development of low-emission isocyanate technologies. This includes the exploration of water-based systems, high-solids formulations, and novel curing mechanisms that reduce or eliminate volatile emissions. Additionally, there has been a growing interest in bio-based isocyanates derived from renewable resources, aligning with broader sustainability goals.

The impact of environmental regulations has extended beyond product formulations to manufacturing processes. Companies have implemented improved emission control technologies and adopted more efficient production methods to reduce their environmental footprint. This has led to the development of closed-loop systems and advanced filtration technologies that minimize the release of isocyanates and related compounds into the environment.

Life Cycle Assessment of Isocyanate Products

Life Cycle Assessment (LCA) of isocyanate products is a crucial tool for evaluating the environmental impact of these versatile chemicals throughout their entire lifecycle. This comprehensive analysis encompasses raw material extraction, production processes, use phase, and end-of-life disposal or recycling. The assessment typically focuses on key environmental indicators such as greenhouse gas emissions, energy consumption, water usage, and waste generation.

In the context of isocyanate transformations for low-emission solutions, LCA plays a pivotal role in quantifying the potential benefits and trade-offs associated with various product formulations and manufacturing techniques. By examining the entire value chain, researchers and industry professionals can identify hotspots where environmental improvements can be made, ultimately leading to more sustainable isocyanate-based products.

One of the primary areas of focus in isocyanate LCA is the production phase, which often accounts for a significant portion of the overall environmental impact. This includes the synthesis of raw materials, such as toluene diisocyanate (TDI) or methylene diphenyl diisocyanate (MDI), as well as the subsequent polymerization processes. Advanced manufacturing techniques, such as catalytic processes or bio-based feedstocks, are being explored to reduce the carbon footprint of isocyanate production.

The use phase of isocyanate products, particularly in applications like polyurethane foams for insulation or automotive components, presents opportunities for environmental benefits through improved energy efficiency and lightweight materials. LCA studies have shown that the long-term energy savings from isocyanate-based insulation can often outweigh the initial production impacts, highlighting the importance of considering the entire lifecycle when evaluating sustainability.

End-of-life considerations are becoming increasingly important in isocyanate LCA, with a growing focus on recyclability and circular economy principles. Innovative recycling technologies, such as chemical depolymerization or mechanical recycling of polyurethane foams, are being developed to reduce waste and recover valuable raw materials. These advancements not only improve the overall environmental profile of isocyanate products but also contribute to resource conservation and waste reduction goals.

By conducting thorough Life Cycle Assessments, stakeholders in the isocyanate industry can make informed decisions about product design, manufacturing processes, and end-of-life strategies. This holistic approach enables the development of truly sustainable solutions that minimize environmental impact while maintaining the performance and versatility that isocyanates are known for in various applications.

In the context of isocyanate transformations for low-emission solutions, LCA plays a pivotal role in quantifying the potential benefits and trade-offs associated with various product formulations and manufacturing techniques. By examining the entire value chain, researchers and industry professionals can identify hotspots where environmental improvements can be made, ultimately leading to more sustainable isocyanate-based products.

One of the primary areas of focus in isocyanate LCA is the production phase, which often accounts for a significant portion of the overall environmental impact. This includes the synthesis of raw materials, such as toluene diisocyanate (TDI) or methylene diphenyl diisocyanate (MDI), as well as the subsequent polymerization processes. Advanced manufacturing techniques, such as catalytic processes or bio-based feedstocks, are being explored to reduce the carbon footprint of isocyanate production.

The use phase of isocyanate products, particularly in applications like polyurethane foams for insulation or automotive components, presents opportunities for environmental benefits through improved energy efficiency and lightweight materials. LCA studies have shown that the long-term energy savings from isocyanate-based insulation can often outweigh the initial production impacts, highlighting the importance of considering the entire lifecycle when evaluating sustainability.

End-of-life considerations are becoming increasingly important in isocyanate LCA, with a growing focus on recyclability and circular economy principles. Innovative recycling technologies, such as chemical depolymerization or mechanical recycling of polyurethane foams, are being developed to reduce waste and recover valuable raw materials. These advancements not only improve the overall environmental profile of isocyanate products but also contribute to resource conservation and waste reduction goals.

By conducting thorough Life Cycle Assessments, stakeholders in the isocyanate industry can make informed decisions about product design, manufacturing processes, and end-of-life strategies. This holistic approach enables the development of truly sustainable solutions that minimize environmental impact while maintaining the performance and versatility that isocyanates are known for in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!