Isocyanate Developments in Environmental Impact Reduction

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution and Environmental Goals

Isocyanates have played a pivotal role in the chemical industry since their discovery in the early 20th century. Initially developed for their unique reactivity, these compounds quickly became essential in the production of polyurethanes, a versatile class of materials used in various applications. The evolution of isocyanates has been driven by both technological advancements and growing environmental concerns.

In the 1930s, Otto Bayer's groundbreaking work led to the commercial production of polyurethanes, marking the beginning of widespread isocyanate use. The post-World War II era saw rapid expansion in isocyanate applications, particularly in foam production, coatings, and adhesives. However, as industrial use increased, so did awareness of the potential environmental and health impacts associated with these chemicals.

The 1970s and 1980s brought heightened scrutiny of industrial chemicals, including isocyanates. This period saw the introduction of stricter regulations and a growing emphasis on worker safety and environmental protection. In response, the industry began exploring ways to reduce the environmental footprint of isocyanate production and use.

Recent decades have witnessed a significant shift towards more sustainable isocyanate technologies. This includes the development of water-based systems, which reduce volatile organic compound (VOC) emissions, and the exploration of bio-based isocyanates derived from renewable resources. These innovations aim to address concerns about fossil fuel dependency and reduce the carbon footprint of isocyanate production.

The current technological landscape is focused on several key environmental goals. Foremost among these is the reduction of emissions during production and application processes. This involves improving manufacturing efficiency, developing better containment systems, and creating formulations that minimize off-gassing during curing.

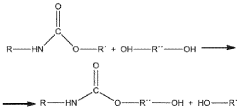

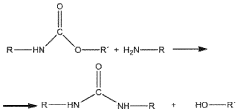

Another critical objective is the development of safer alternatives to traditional isocyanates, particularly those with lower toxicity profiles. This includes research into blocked isocyanates, which remain inert until activated, reducing exposure risks during handling and application.

Recyclability and end-of-life considerations have also become central to isocyanate development. Efforts are underway to create polyurethane products that can be more easily recycled or biodegraded, addressing concerns about long-term environmental persistence.

As the industry moves forward, the integration of green chemistry principles into isocyanate production is becoming increasingly important. This holistic approach considers the entire lifecycle of isocyanate-based products, from raw material sourcing to disposal, aiming to minimize environmental impact at every stage.

In the 1930s, Otto Bayer's groundbreaking work led to the commercial production of polyurethanes, marking the beginning of widespread isocyanate use. The post-World War II era saw rapid expansion in isocyanate applications, particularly in foam production, coatings, and adhesives. However, as industrial use increased, so did awareness of the potential environmental and health impacts associated with these chemicals.

The 1970s and 1980s brought heightened scrutiny of industrial chemicals, including isocyanates. This period saw the introduction of stricter regulations and a growing emphasis on worker safety and environmental protection. In response, the industry began exploring ways to reduce the environmental footprint of isocyanate production and use.

Recent decades have witnessed a significant shift towards more sustainable isocyanate technologies. This includes the development of water-based systems, which reduce volatile organic compound (VOC) emissions, and the exploration of bio-based isocyanates derived from renewable resources. These innovations aim to address concerns about fossil fuel dependency and reduce the carbon footprint of isocyanate production.

The current technological landscape is focused on several key environmental goals. Foremost among these is the reduction of emissions during production and application processes. This involves improving manufacturing efficiency, developing better containment systems, and creating formulations that minimize off-gassing during curing.

Another critical objective is the development of safer alternatives to traditional isocyanates, particularly those with lower toxicity profiles. This includes research into blocked isocyanates, which remain inert until activated, reducing exposure risks during handling and application.

Recyclability and end-of-life considerations have also become central to isocyanate development. Efforts are underway to create polyurethane products that can be more easily recycled or biodegraded, addressing concerns about long-term environmental persistence.

As the industry moves forward, the integration of green chemistry principles into isocyanate production is becoming increasingly important. This holistic approach considers the entire lifecycle of isocyanate-based products, from raw material sourcing to disposal, aiming to minimize environmental impact at every stage.

Market Demand for Eco-Friendly Isocyanates

The market demand for eco-friendly isocyanates has been steadily increasing in recent years, driven by growing environmental concerns and stringent regulations. This shift is particularly evident in key industries such as automotive, construction, and furniture manufacturing, where isocyanates are widely used in the production of polyurethanes.

In the automotive sector, there is a significant push towards lightweight materials to improve fuel efficiency and reduce emissions. Eco-friendly isocyanates play a crucial role in developing sustainable polyurethane foams for vehicle interiors, seats, and insulation. Major automakers are actively seeking suppliers who can provide environmentally responsible alternatives to traditional isocyanates.

The construction industry is another major driver of demand for green isocyanates. With the global focus on sustainable building practices, there is a growing need for eco-friendly insulation materials and coatings. Isocyanates with reduced environmental impact are being incorporated into spray foams, sealants, and adhesives used in energy-efficient buildings.

Furniture manufacturers are also contributing to the market demand as consumers become more environmentally conscious. The industry is moving towards bio-based polyurethanes for mattresses, upholstery, and other foam-based products. This trend is particularly strong in developed markets where consumers are willing to pay a premium for sustainable products.

The packaging industry is emerging as a new frontier for eco-friendly isocyanates. As e-commerce continues to grow, there is an increasing demand for sustainable packaging solutions. Isocyanate-based adhesives and coatings with reduced environmental impact are being developed to meet this need.

Geographically, the demand for eco-friendly isocyanates is most pronounced in regions with strict environmental regulations, such as the European Union and North America. However, developing markets in Asia-Pacific are also showing increased interest as they adopt more stringent environmental policies.

Market analysts project substantial growth in the eco-friendly isocyanate sector over the next decade. This growth is expected to be driven by ongoing research and development efforts to improve the performance and cost-effectiveness of these materials, as well as increasing consumer awareness and regulatory pressures.

In the automotive sector, there is a significant push towards lightweight materials to improve fuel efficiency and reduce emissions. Eco-friendly isocyanates play a crucial role in developing sustainable polyurethane foams for vehicle interiors, seats, and insulation. Major automakers are actively seeking suppliers who can provide environmentally responsible alternatives to traditional isocyanates.

The construction industry is another major driver of demand for green isocyanates. With the global focus on sustainable building practices, there is a growing need for eco-friendly insulation materials and coatings. Isocyanates with reduced environmental impact are being incorporated into spray foams, sealants, and adhesives used in energy-efficient buildings.

Furniture manufacturers are also contributing to the market demand as consumers become more environmentally conscious. The industry is moving towards bio-based polyurethanes for mattresses, upholstery, and other foam-based products. This trend is particularly strong in developed markets where consumers are willing to pay a premium for sustainable products.

The packaging industry is emerging as a new frontier for eco-friendly isocyanates. As e-commerce continues to grow, there is an increasing demand for sustainable packaging solutions. Isocyanate-based adhesives and coatings with reduced environmental impact are being developed to meet this need.

Geographically, the demand for eco-friendly isocyanates is most pronounced in regions with strict environmental regulations, such as the European Union and North America. However, developing markets in Asia-Pacific are also showing increased interest as they adopt more stringent environmental policies.

Market analysts project substantial growth in the eco-friendly isocyanate sector over the next decade. This growth is expected to be driven by ongoing research and development efforts to improve the performance and cost-effectiveness of these materials, as well as increasing consumer awareness and regulatory pressures.

Current Challenges in Isocyanate Environmental Impact

Isocyanates, widely used in the production of polyurethanes, face significant environmental challenges due to their potential harmful effects on human health and ecosystems. The primary concern is their high reactivity with water, which can lead to the formation of toxic by-products and contribute to air and water pollution. This reactivity also poses risks during production, transportation, and application processes, necessitating stringent safety measures and specialized handling procedures.

One of the major challenges in reducing the environmental impact of isocyanates is their persistence in the environment. These compounds can remain stable for extended periods, potentially accumulating in soil and water bodies. This persistence complicates remediation efforts and increases the risk of long-term environmental damage. Additionally, the breakdown products of isocyanates, such as amines, can also have detrimental effects on aquatic life and ecosystems.

The volatile nature of many isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), contributes to air quality issues. These compounds can easily become airborne during manufacturing and application processes, leading to potential respiratory hazards for workers and nearby communities. Controlling these emissions requires sophisticated ventilation systems and personal protective equipment, which can be costly and energy-intensive.

Another significant challenge is the lack of environmentally friendly alternatives that can match the performance characteristics of isocyanates in various applications. While some bio-based and low-VOC alternatives have been developed, they often fall short in terms of durability, cost-effectiveness, or specific performance attributes. This limitation hinders the widespread adoption of more sustainable options in industries heavily reliant on isocyanate-based products.

The disposal of isocyanate-containing waste presents additional environmental concerns. Improper disposal can lead to soil and groundwater contamination, posing risks to both human health and ecosystems. Developing effective and economically viable methods for the safe disposal or recycling of isocyanate waste remains a significant challenge for the industry.

Regulatory compliance and evolving environmental standards also pose ongoing challenges for isocyanate manufacturers and users. Stricter regulations on emissions, exposure limits, and waste management require continuous adaptation of production processes and product formulations. Balancing these regulatory requirements with maintaining product performance and economic viability is a complex task for the industry.

One of the major challenges in reducing the environmental impact of isocyanates is their persistence in the environment. These compounds can remain stable for extended periods, potentially accumulating in soil and water bodies. This persistence complicates remediation efforts and increases the risk of long-term environmental damage. Additionally, the breakdown products of isocyanates, such as amines, can also have detrimental effects on aquatic life and ecosystems.

The volatile nature of many isocyanates, particularly methylene diphenyl diisocyanate (MDI) and toluene diisocyanate (TDI), contributes to air quality issues. These compounds can easily become airborne during manufacturing and application processes, leading to potential respiratory hazards for workers and nearby communities. Controlling these emissions requires sophisticated ventilation systems and personal protective equipment, which can be costly and energy-intensive.

Another significant challenge is the lack of environmentally friendly alternatives that can match the performance characteristics of isocyanates in various applications. While some bio-based and low-VOC alternatives have been developed, they often fall short in terms of durability, cost-effectiveness, or specific performance attributes. This limitation hinders the widespread adoption of more sustainable options in industries heavily reliant on isocyanate-based products.

The disposal of isocyanate-containing waste presents additional environmental concerns. Improper disposal can lead to soil and groundwater contamination, posing risks to both human health and ecosystems. Developing effective and economically viable methods for the safe disposal or recycling of isocyanate waste remains a significant challenge for the industry.

Regulatory compliance and evolving environmental standards also pose ongoing challenges for isocyanate manufacturers and users. Stricter regulations on emissions, exposure limits, and waste management require continuous adaptation of production processes and product formulations. Balancing these regulatory requirements with maintaining product performance and economic viability is a complex task for the industry.

Existing Green Isocyanate Solutions

01 Environmental impact assessment of isocyanates

Isocyanates are known to have potential environmental impacts. Assessments are conducted to evaluate their effects on air, water, and soil quality. These studies help in understanding the persistence, bioaccumulation, and toxicity of isocyanates in various ecosystems. The results of such assessments inform regulatory decisions and guide the development of more environmentally friendly alternatives.- Environmental impact assessment of isocyanates: Isocyanates are known to have potential environmental impacts. Comprehensive assessments are conducted to evaluate their effects on air, water, and soil quality. These assessments consider factors such as toxicity, persistence, and bioaccumulation potential. The results inform regulatory decisions and guide the development of mitigation strategies.

- Emission control and reduction techniques: Various techniques are employed to control and reduce isocyanate emissions in industrial processes. These may include advanced scrubbing systems, catalytic oxidation, and closed-loop manufacturing processes. Implementing these technologies helps minimize the release of isocyanates into the environment, thereby reducing their potential ecological impact.

- Biodegradable alternatives to traditional isocyanates: Research is ongoing to develop biodegradable alternatives to traditional isocyanates. These eco-friendly substitutes aim to maintain the desired chemical properties while reducing environmental persistence and toxicity. Such innovations could significantly decrease the long-term environmental impact of isocyanate-based products.

- Monitoring and detection systems for isocyanate pollution: Advanced monitoring and detection systems are being developed to track isocyanate pollution in various environmental media. These systems utilize sensors, data analytics, and real-time reporting to provide early warnings of potential contamination. Improved monitoring capabilities enable faster response times and more effective environmental protection measures.

- Regulatory compliance and environmental management: Industries using isocyanates are subject to strict regulatory compliance and environmental management protocols. This includes implementing environmental management systems, conducting regular audits, and reporting on environmental performance. These measures aim to ensure responsible use of isocyanates and minimize their impact on ecosystems and human health.

02 Reduction of isocyanate emissions in industrial processes

Efforts are being made to reduce isocyanate emissions in industrial settings. This includes the development of improved production processes, better containment systems, and more efficient emission control technologies. These measures aim to minimize the release of isocyanates into the environment, thereby reducing their potential impact on air quality and worker health.Expand Specific Solutions03 Biodegradable alternatives to traditional isocyanates

Research is ongoing to develop biodegradable alternatives to traditional isocyanates. These new materials aim to provide similar performance characteristics while being more environmentally friendly. The focus is on creating substances that break down more easily in natural environments, reducing long-term environmental impacts and potential harm to ecosystems.Expand Specific Solutions04 Monitoring and control systems for isocyanate use

Advanced monitoring and control systems are being implemented to manage isocyanate use in industrial settings. These systems help in real-time tracking of isocyanate levels, ensuring compliance with environmental regulations, and minimizing accidental releases. They play a crucial role in reducing the environmental footprint of isocyanate-using industries.Expand Specific Solutions05 Life cycle assessment of isocyanate-based products

Life cycle assessments are being conducted on isocyanate-based products to understand their overall environmental impact from production to disposal. These studies consider factors such as resource consumption, energy use, emissions, and end-of-life scenarios. The results help in identifying areas for improvement and guide the development of more sustainable product designs and manufacturing processes.Expand Specific Solutions

Key Players in Sustainable Isocyanate Production

The isocyanate industry for environmental impact reduction is in a transitional phase, with growing market demand driven by sustainability concerns. The global market size is expanding, projected to reach several billion dollars by 2025. Technologically, advancements are progressing but still maturing. Key players like Wanhua Chemical, BASF, Covestro, and Mitsui Chemicals are investing heavily in R&D to develop eco-friendly isocyanates. These companies are focusing on bio-based raw materials, reduced emissions processes, and improved end-product recyclability. Smaller firms and research institutions are also contributing innovative solutions, indicating a competitive and dynamic landscape.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed innovative isocyanate technologies to reduce environmental impact. Their approach includes the use of water-based polyurethane dispersions (PUDs) for coatings and adhesives, which significantly lower volatile organic compound (VOC) emissions[1]. They have also implemented a novel gas-phase phosgenation process for producing isocyanates, which reduces energy consumption by up to 40% compared to traditional liquid-phase methods[2]. Additionally, Wanhua has invested in bio-based isocyanates derived from renewable resources, aiming to decrease reliance on fossil fuels and reduce carbon footprint[3]. Their continuous research focuses on improving catalysts and process efficiency to minimize waste and energy use in isocyanate production.

Strengths: Advanced water-based technologies, energy-efficient production processes, and commitment to bio-based alternatives. Weaknesses: Potential higher production costs for eco-friendly options and the need for extensive market education on new sustainable products.

BASF Corp.

Technical Solution: BASF has made significant strides in reducing the environmental impact of isocyanates through various innovative approaches. They have developed a novel aliphatic isocyanate, Basonat® eco, which is partially derived from renewable raw materials, reducing the carbon footprint by up to 40% compared to conventional products[1]. BASF has also introduced water-based polyurethane systems that minimize VOC emissions and improve indoor air quality[2]. Their research extends to optimizing production processes, implementing closed-loop recycling systems for isocyanate waste, and developing isocyanate-free alternatives for specific applications[3]. Additionally, BASF has invested in improving the safety profile of isocyanates by designing products with reduced vapor pressure and implementing advanced handling technologies to minimize exposure risks[4].

Strengths: Strong focus on renewable raw materials, comprehensive approach to sustainability, and advanced safety measures. Weaknesses: Potential higher costs associated with eco-friendly products and the challenge of maintaining performance while reducing environmental impact.

Innovative Eco-Friendly Isocyanate Technologies

Method for isocyanate and polyurethane production with improved sustainability

PatentWO2021089737A1

Innovation

- A process that recycles polyurethane waste through pyrolysis and reverse water gas shift reaction, utilizing renewable energy for hydrogen and oxygen production, and closed-loop carbon dioxide recycling to produce isocyanates and polyurethanes, reducing fossil raw material use and carbon emissions.

Isocyanates modified for being provided with surfactant property, composition containing same, resulting coating

PatentInactiveEP0973782A1

Innovation

- Development of modified isocyanates with surfactant properties that can be easily dispersed in an aqueous phase, reducing solvent content to less than 1/5 by mass, and using a composition comprising specific compounds and surfactants to create self-emulsifying isocyanate compositions that do not require specific emulsification techniques, allowing for the production of high-quality coatings without organic solvents.

Regulatory Framework for Isocyanate Use

The regulatory framework for isocyanate use has evolved significantly in recent years, driven by growing concerns over environmental and health impacts. Globally, regulatory bodies have implemented stringent measures to control the production, handling, and disposal of isocyanates, recognizing their potential hazards to human health and the environment.

In the United States, the Environmental Protection Agency (EPA) has established comprehensive regulations under the Toxic Substances Control Act (TSCA). These regulations mandate strict reporting, record-keeping, and testing requirements for companies that manufacture, import, or process isocyanates. The Occupational Safety and Health Administration (OSHA) has also set permissible exposure limits and requires employers to implement safety measures to protect workers from isocyanate exposure.

The European Union has taken a proactive approach through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers must register isocyanates and provide detailed information on their properties, hazards, and safe use. The EU has also imposed restrictions on certain isocyanates in consumer products, particularly in spray applications.

In Asia, countries like China and Japan have strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has included isocyanates in its list of priority controlled chemicals, requiring manufacturers to obtain permits and implement pollution control measures. Japan's Chemical Substances Control Law mandates strict reporting and assessment of isocyanates' environmental and health impacts.

International agreements, such as the Stockholm Convention on Persistent Organic Pollutants, have also influenced isocyanate regulations. While isocyanates are not currently listed as persistent organic pollutants, the convention's principles have encouraged countries to adopt precautionary approaches in managing these chemicals.

The regulatory landscape continues to evolve, with a trend towards more stringent controls and increased emphasis on sustainable alternatives. Many jurisdictions are now focusing on promoting the development and adoption of low-VOC (volatile organic compound) and water-based alternatives to traditional isocyanate-based products. This shift is particularly evident in the coatings and adhesives industries, where regulatory pressure has spurred innovation in environmentally friendly formulations.

As environmental concerns grow, regulators are also placing greater emphasis on lifecycle assessments of isocyanate-containing products. This holistic approach considers the environmental impact from production to disposal, encouraging manufacturers to adopt more sustainable practices throughout the product lifecycle. The trend towards circular economy principles is likely to further influence future regulatory frameworks, potentially leading to extended producer responsibility for isocyanate-based products.

In the United States, the Environmental Protection Agency (EPA) has established comprehensive regulations under the Toxic Substances Control Act (TSCA). These regulations mandate strict reporting, record-keeping, and testing requirements for companies that manufacture, import, or process isocyanates. The Occupational Safety and Health Administration (OSHA) has also set permissible exposure limits and requires employers to implement safety measures to protect workers from isocyanate exposure.

The European Union has taken a proactive approach through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers must register isocyanates and provide detailed information on their properties, hazards, and safe use. The EU has also imposed restrictions on certain isocyanates in consumer products, particularly in spray applications.

In Asia, countries like China and Japan have strengthened their regulatory frameworks. China's Ministry of Ecology and Environment has included isocyanates in its list of priority controlled chemicals, requiring manufacturers to obtain permits and implement pollution control measures. Japan's Chemical Substances Control Law mandates strict reporting and assessment of isocyanates' environmental and health impacts.

International agreements, such as the Stockholm Convention on Persistent Organic Pollutants, have also influenced isocyanate regulations. While isocyanates are not currently listed as persistent organic pollutants, the convention's principles have encouraged countries to adopt precautionary approaches in managing these chemicals.

The regulatory landscape continues to evolve, with a trend towards more stringent controls and increased emphasis on sustainable alternatives. Many jurisdictions are now focusing on promoting the development and adoption of low-VOC (volatile organic compound) and water-based alternatives to traditional isocyanate-based products. This shift is particularly evident in the coatings and adhesives industries, where regulatory pressure has spurred innovation in environmentally friendly formulations.

As environmental concerns grow, regulators are also placing greater emphasis on lifecycle assessments of isocyanate-containing products. This holistic approach considers the environmental impact from production to disposal, encouraging manufacturers to adopt more sustainable practices throughout the product lifecycle. The trend towards circular economy principles is likely to further influence future regulatory frameworks, potentially leading to extended producer responsibility for isocyanate-based products.

Life Cycle Assessment of Isocyanate Products

Life Cycle Assessment (LCA) of isocyanate products has become increasingly important in evaluating and mitigating the environmental impact of these widely used chemicals. This comprehensive approach examines the entire lifecycle of isocyanate-based products, from raw material extraction to disposal or recycling, providing valuable insights into their overall environmental footprint.

The production phase of isocyanates typically involves energy-intensive processes and the use of fossil fuel-based feedstocks. LCA studies have shown that this stage often contributes significantly to the overall environmental impact. However, recent advancements in production technologies and the use of renewable feedstocks have demonstrated potential for reducing greenhouse gas emissions and energy consumption during manufacturing.

In the use phase, isocyanate products, particularly polyurethanes, often exhibit positive environmental attributes. Their excellent insulation properties, for instance, contribute to energy savings in buildings and refrigeration systems. Additionally, the durability and lightweight nature of many isocyanate-based materials can lead to reduced fuel consumption in transportation applications.

End-of-life considerations for isocyanate products have been a focus of recent LCA studies. While some products can be challenging to recycle due to their complex chemical structure, innovative recycling technologies are emerging. Chemical recycling methods, such as glycolysis and acidolysis, show promise in breaking down polyurethane foams into reusable raw materials, potentially closing the loop in the product lifecycle.

LCA results have highlighted areas for improvement in isocyanate product sustainability. Water consumption and ecotoxicity impacts during production have been identified as key areas for mitigation. In response, industry efforts have focused on developing water-based systems and reducing the use of harmful solvents.

Comparative LCAs between isocyanate-based products and alternatives have provided valuable insights for decision-making. In many applications, such as insulation and automotive components, isocyanate products often demonstrate lower overall environmental impacts when considering their entire lifecycle, particularly due to their energy-saving properties during use.

The application of LCA methodologies to isocyanate products has driven innovation in the industry. It has spurred the development of bio-based isocyanates, which show potential for reducing dependence on fossil resources and lowering carbon footprints. Additionally, LCA findings have encouraged the optimization of production processes, leading to more efficient use of resources and reduced emissions.

The production phase of isocyanates typically involves energy-intensive processes and the use of fossil fuel-based feedstocks. LCA studies have shown that this stage often contributes significantly to the overall environmental impact. However, recent advancements in production technologies and the use of renewable feedstocks have demonstrated potential for reducing greenhouse gas emissions and energy consumption during manufacturing.

In the use phase, isocyanate products, particularly polyurethanes, often exhibit positive environmental attributes. Their excellent insulation properties, for instance, contribute to energy savings in buildings and refrigeration systems. Additionally, the durability and lightweight nature of many isocyanate-based materials can lead to reduced fuel consumption in transportation applications.

End-of-life considerations for isocyanate products have been a focus of recent LCA studies. While some products can be challenging to recycle due to their complex chemical structure, innovative recycling technologies are emerging. Chemical recycling methods, such as glycolysis and acidolysis, show promise in breaking down polyurethane foams into reusable raw materials, potentially closing the loop in the product lifecycle.

LCA results have highlighted areas for improvement in isocyanate product sustainability. Water consumption and ecotoxicity impacts during production have been identified as key areas for mitigation. In response, industry efforts have focused on developing water-based systems and reducing the use of harmful solvents.

Comparative LCAs between isocyanate-based products and alternatives have provided valuable insights for decision-making. In many applications, such as insulation and automotive components, isocyanate products often demonstrate lower overall environmental impacts when considering their entire lifecycle, particularly due to their energy-saving properties during use.

The application of LCA methodologies to isocyanate products has driven innovation in the industry. It has spurred the development of bio-based isocyanates, which show potential for reducing dependence on fossil resources and lowering carbon footprints. Additionally, LCA findings have encouraged the optimization of production processes, leading to more efficient use of resources and reduced emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!