How to Implement Isocyanate Sustainability Initiatives?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Sustainability Background and Objectives

Isocyanates have been a cornerstone in the production of polyurethanes for decades, finding applications in various industries such as automotive, construction, and furniture manufacturing. However, the sustainability of isocyanate-based products has come under scrutiny due to environmental and health concerns. This has led to a growing need for sustainable initiatives in the isocyanate industry.

The evolution of isocyanate technology can be traced back to the 1930s when Otto Bayer and his team at IG Farben discovered the polyaddition reaction between diisocyanates and polyols. This breakthrough laid the foundation for the polyurethane industry. Over the years, the technology has advanced significantly, with improvements in production processes, product performance, and safety measures.

Current trends in isocyanate sustainability focus on several key areas. One major trend is the development of bio-based isocyanates, which aim to reduce reliance on fossil fuels and decrease the carbon footprint of polyurethane products. Another important trend is the implementation of more efficient production processes that minimize waste and energy consumption. Additionally, there is a growing emphasis on improving end-of-life management for isocyanate-based products, including recycling and biodegradation.

The primary objective of isocyanate sustainability initiatives is to address the environmental and health concerns associated with these chemicals while maintaining their valuable properties and applications. This involves developing safer alternatives, reducing emissions during production and use, and improving the overall lifecycle impact of isocyanate-based products.

Key technical goals in this field include the development of non-toxic or less toxic isocyanate alternatives, the creation of more efficient catalysts for isocyanate production, and the design of novel recycling technologies for polyurethane products. There is also a focus on improving the durability and longevity of isocyanate-based materials to reduce the need for frequent replacement and disposal.

Another important objective is to enhance the transparency and traceability of isocyanate supply chains. This involves implementing better monitoring and reporting systems to track the environmental and social impacts of isocyanate production and use throughout the product lifecycle.

Regulatory compliance is also a crucial aspect of isocyanate sustainability initiatives. As environmental regulations become more stringent, companies must adapt their processes and products to meet new standards. This includes reducing volatile organic compound (VOC) emissions, implementing safer handling practices, and developing products that comply with emerging green building standards.

The evolution of isocyanate technology can be traced back to the 1930s when Otto Bayer and his team at IG Farben discovered the polyaddition reaction between diisocyanates and polyols. This breakthrough laid the foundation for the polyurethane industry. Over the years, the technology has advanced significantly, with improvements in production processes, product performance, and safety measures.

Current trends in isocyanate sustainability focus on several key areas. One major trend is the development of bio-based isocyanates, which aim to reduce reliance on fossil fuels and decrease the carbon footprint of polyurethane products. Another important trend is the implementation of more efficient production processes that minimize waste and energy consumption. Additionally, there is a growing emphasis on improving end-of-life management for isocyanate-based products, including recycling and biodegradation.

The primary objective of isocyanate sustainability initiatives is to address the environmental and health concerns associated with these chemicals while maintaining their valuable properties and applications. This involves developing safer alternatives, reducing emissions during production and use, and improving the overall lifecycle impact of isocyanate-based products.

Key technical goals in this field include the development of non-toxic or less toxic isocyanate alternatives, the creation of more efficient catalysts for isocyanate production, and the design of novel recycling technologies for polyurethane products. There is also a focus on improving the durability and longevity of isocyanate-based materials to reduce the need for frequent replacement and disposal.

Another important objective is to enhance the transparency and traceability of isocyanate supply chains. This involves implementing better monitoring and reporting systems to track the environmental and social impacts of isocyanate production and use throughout the product lifecycle.

Regulatory compliance is also a crucial aspect of isocyanate sustainability initiatives. As environmental regulations become more stringent, companies must adapt their processes and products to meet new standards. This includes reducing volatile organic compound (VOC) emissions, implementing safer handling practices, and developing products that comply with emerging green building standards.

Market Demand for Sustainable Isocyanate Solutions

The market demand for sustainable isocyanate solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations. Isocyanates, widely used in the production of polyurethanes, have traditionally been associated with environmental and health risks. This has led to a significant shift in consumer preferences and industry practices towards more sustainable alternatives.

In the construction sector, which accounts for a substantial portion of isocyanate consumption, there is a rising demand for eco-friendly insulation materials and coatings. Building developers and contractors are increasingly seeking sustainable isocyanate-based products that offer improved energy efficiency and reduced environmental impact. This trend is particularly pronounced in green building projects, where certification systems like LEED and BREEAM are driving the adoption of sustainable materials.

The automotive industry, another major consumer of isocyanates, is also experiencing a surge in demand for sustainable solutions. As vehicle manufacturers strive to reduce the carbon footprint of their products, there is a growing interest in bio-based isocyanates and recyclable polyurethane components. This shift is partly driven by stringent emissions regulations and the increasing consumer preference for environmentally friendly vehicles.

In the furniture and bedding industry, concerns about indoor air quality and off-gassing have led to increased demand for low-emission isocyanate products. Consumers are willing to pay a premium for furniture and mattresses that use sustainable isocyanate-based foams, which offer reduced VOC emissions and improved durability.

The packaging industry is another sector where the demand for sustainable isocyanate solutions is on the rise. With the growing emphasis on recyclable and biodegradable packaging materials, manufacturers are exploring isocyanate-based adhesives and coatings that are more environmentally friendly and support circular economy principles.

The textile industry is also witnessing a shift towards sustainable isocyanate applications, particularly in the production of waterproof and breathable fabrics. Outdoor apparel and sportswear brands are increasingly seeking eco-friendly alternatives to traditional isocyanate-based coatings, responding to consumer demand for sustainable and high-performance products.

Market research indicates that the global demand for sustainable isocyanate solutions is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is driven not only by regulatory pressures but also by voluntary corporate sustainability initiatives and changing consumer preferences. Companies that can offer innovative, sustainable isocyanate products are likely to gain a significant competitive advantage in this evolving market landscape.

In the construction sector, which accounts for a substantial portion of isocyanate consumption, there is a rising demand for eco-friendly insulation materials and coatings. Building developers and contractors are increasingly seeking sustainable isocyanate-based products that offer improved energy efficiency and reduced environmental impact. This trend is particularly pronounced in green building projects, where certification systems like LEED and BREEAM are driving the adoption of sustainable materials.

The automotive industry, another major consumer of isocyanates, is also experiencing a surge in demand for sustainable solutions. As vehicle manufacturers strive to reduce the carbon footprint of their products, there is a growing interest in bio-based isocyanates and recyclable polyurethane components. This shift is partly driven by stringent emissions regulations and the increasing consumer preference for environmentally friendly vehicles.

In the furniture and bedding industry, concerns about indoor air quality and off-gassing have led to increased demand for low-emission isocyanate products. Consumers are willing to pay a premium for furniture and mattresses that use sustainable isocyanate-based foams, which offer reduced VOC emissions and improved durability.

The packaging industry is another sector where the demand for sustainable isocyanate solutions is on the rise. With the growing emphasis on recyclable and biodegradable packaging materials, manufacturers are exploring isocyanate-based adhesives and coatings that are more environmentally friendly and support circular economy principles.

The textile industry is also witnessing a shift towards sustainable isocyanate applications, particularly in the production of waterproof and breathable fabrics. Outdoor apparel and sportswear brands are increasingly seeking eco-friendly alternatives to traditional isocyanate-based coatings, responding to consumer demand for sustainable and high-performance products.

Market research indicates that the global demand for sustainable isocyanate solutions is expected to grow at a compound annual growth rate (CAGR) of over 5% in the next five years. This growth is driven not only by regulatory pressures but also by voluntary corporate sustainability initiatives and changing consumer preferences. Companies that can offer innovative, sustainable isocyanate products are likely to gain a significant competitive advantage in this evolving market landscape.

Current Challenges in Isocyanate Sustainability

The implementation of isocyanate sustainability initiatives faces several significant challenges in the current landscape. One of the primary obstacles is the inherent toxicity of isocyanates, which poses risks to both human health and the environment. Despite their widespread use in various industries, including automotive, construction, and furniture manufacturing, the potential hazards associated with isocyanate exposure have led to increased scrutiny and regulatory pressure.

Another major challenge lies in the production process of isocyanates, which traditionally relies heavily on fossil fuel-based raw materials. This dependency not only contributes to carbon emissions but also raises concerns about long-term resource availability and price volatility. The industry is grappling with the need to transition towards more sustainable feedstocks and production methods while maintaining product quality and economic viability.

The lack of standardized sustainability metrics and reporting frameworks specific to isocyanate production and use presents a significant hurdle. This absence makes it difficult for companies to accurately measure, compare, and communicate their sustainability efforts, hindering progress and transparency across the industry. Additionally, the complex supply chain involved in isocyanate production and application further complicates the implementation of comprehensive sustainability initiatives.

Technological limitations also pose challenges in achieving isocyanate sustainability. While alternative production methods and safer substitutes are being researched, many of these solutions are still in early development stages or face scalability issues. The high performance standards required in many applications make it challenging to find suitable replacements that can match the unique properties of isocyanates without compromising product quality or functionality.

Furthermore, the economic implications of transitioning to more sustainable practices present a significant barrier. Many companies face the dilemma of balancing short-term financial pressures with long-term sustainability goals. The initial investment required for adopting new technologies, reformulating products, or overhauling production processes can be substantial, deterring some organizations from taking decisive action.

Lastly, the fragmented nature of sustainability efforts across different regions and sectors hampers the development of a unified approach to isocyanate sustainability. Varying regulatory requirements, market demands, and industry practices across different countries and industries create a complex landscape for implementing consistent and effective sustainability initiatives on a global scale.

Another major challenge lies in the production process of isocyanates, which traditionally relies heavily on fossil fuel-based raw materials. This dependency not only contributes to carbon emissions but also raises concerns about long-term resource availability and price volatility. The industry is grappling with the need to transition towards more sustainable feedstocks and production methods while maintaining product quality and economic viability.

The lack of standardized sustainability metrics and reporting frameworks specific to isocyanate production and use presents a significant hurdle. This absence makes it difficult for companies to accurately measure, compare, and communicate their sustainability efforts, hindering progress and transparency across the industry. Additionally, the complex supply chain involved in isocyanate production and application further complicates the implementation of comprehensive sustainability initiatives.

Technological limitations also pose challenges in achieving isocyanate sustainability. While alternative production methods and safer substitutes are being researched, many of these solutions are still in early development stages or face scalability issues. The high performance standards required in many applications make it challenging to find suitable replacements that can match the unique properties of isocyanates without compromising product quality or functionality.

Furthermore, the economic implications of transitioning to more sustainable practices present a significant barrier. Many companies face the dilemma of balancing short-term financial pressures with long-term sustainability goals. The initial investment required for adopting new technologies, reformulating products, or overhauling production processes can be substantial, deterring some organizations from taking decisive action.

Lastly, the fragmented nature of sustainability efforts across different regions and sectors hampers the development of a unified approach to isocyanate sustainability. Varying regulatory requirements, market demands, and industry practices across different countries and industries create a complex landscape for implementing consistent and effective sustainability initiatives on a global scale.

Existing Isocyanate Sustainability Implementations

01 Bio-based isocyanates

Development of sustainable isocyanates derived from renewable resources, such as plant-based oils or biomass. These bio-based alternatives aim to reduce reliance on petroleum-derived raw materials and decrease the environmental impact of isocyanate production.- Bio-based isocyanates: Development of sustainable isocyanates derived from renewable resources, such as plant-based oils or biomass. These bio-based alternatives aim to reduce reliance on petroleum-derived raw materials and decrease the environmental impact of isocyanate production.

- Isocyanate-free polyurethane systems: Research into alternative polyurethane formulations that do not require isocyanates, focusing on sustainable chemistries and raw materials. These systems aim to maintain performance while eliminating concerns associated with traditional isocyanate-based polyurethanes.

- Recycling and circular economy approaches: Development of technologies and processes for recycling isocyanate-based products, such as polyurethane foams and coatings. These approaches aim to create a circular economy for isocyanate-containing materials, reducing waste and improving sustainability.

- Low-emission isocyanate formulations: Innovations in isocyanate formulations to reduce emissions during application and curing processes. These advancements focus on improving worker safety and minimizing environmental impact while maintaining product performance.

- Energy-efficient isocyanate production: Development of more energy-efficient processes for isocyanate production, including improved catalysts, reactor designs, and process optimizations. These innovations aim to reduce the carbon footprint and overall environmental impact of isocyanate manufacturing.

02 Isocyanate-free polyurethane systems

Research into alternative polyurethane formulations that do not require isocyanates, focusing on sustainable chemistries and raw materials. These systems aim to maintain performance while eliminating concerns associated with isocyanate handling and exposure.Expand Specific Solutions03 Recycling and circular economy approaches

Development of technologies and processes for recycling isocyanate-based products, such as polyurethane foams and coatings. These approaches aim to create a circular economy for isocyanate-containing materials, reducing waste and improving sustainability.Expand Specific Solutions04 Low-emission and low-VOC isocyanate formulations

Advancements in isocyanate formulations to reduce emissions and volatile organic compound (VOC) content. These improvements focus on enhancing worker safety and minimizing environmental impact during application and curing processes.Expand Specific Solutions05 Energy-efficient isocyanate production

Innovations in manufacturing processes to improve energy efficiency and reduce the carbon footprint of isocyanate production. These advancements may include process optimizations, catalysis improvements, and the use of renewable energy sources in manufacturing facilities.Expand Specific Solutions

Key Players in Sustainable Isocyanate Industry

The implementation of isocyanate sustainability initiatives is in a transitional phase, with the market showing significant growth potential. The global isocyanate market is expanding due to increasing demand in various industries, particularly construction and automotive. Technologically, the field is advancing rapidly, with major players like Wanhua Chemical Group, BASF, and Covestro leading innovation efforts. These companies are focusing on developing eco-friendly alternatives and improving production processes to reduce environmental impact. Smaller firms and research institutions are also contributing to technological advancements, creating a competitive landscape that drives sustainable solutions in the isocyanate industry.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed a comprehensive isocyanate sustainability initiative focusing on green chemistry principles. They have implemented a closed-loop production system that recycles and reuses raw materials, reducing waste by up to 30%[1]. Their innovative MDI (methylene diphenyl diisocyanate) production process uses carbon dioxide as a raw material, effectively reducing carbon emissions by 10-15% compared to traditional methods[2]. Additionally, Wanhua has invested in bio-based polyols derived from renewable resources, which can be used in conjunction with isocyanates to produce more sustainable polyurethane products[3]. The company has also developed water-based polyurethane dispersions, reducing the use of volatile organic compounds (VOCs) in various applications.

Strengths: Integrated production chain, innovative CO2 utilization, and bio-based raw materials. Weaknesses: High initial investment costs for new technologies and potential challenges in scaling up bio-based raw material production.

BASF Corp.

Technical Solution: BASF has implemented a multi-faceted approach to isocyanate sustainability. Their "Biomass Balance" approach involves using renewable raw materials in the production of isocyanates, reducing fossil resource consumption by up to 50%[4]. BASF has also developed a novel aliphatic isocyanate, Basonat®, which is 100% solvent-free and low-monomer, significantly reducing VOC emissions and improving worker safety[5]. The company's ChemCycling™ project focuses on chemical recycling of plastic waste, including polyurethane materials, to produce new isocyanates, creating a circular economy model[6]. Furthermore, BASF has invested in energy-efficient production processes, reducing the carbon footprint of isocyanate production by approximately 25% over the past decade.

Strengths: Strong R&D capabilities, diverse sustainability initiatives, and global market presence. Weaknesses: Dependency on the availability of renewable raw materials and potential higher costs for sustainable products.

Innovative Approaches to Isocyanate Sustainability

Sustainable preparation of organic amino compounds for the production of organic isocyanates

PatentWO2024017890A2

Innovation

- A process using green hydrogen and green ammonia to produce organic amino compounds, which are then used to synthesize isocyanates, incorporating renewable energy sources and reducing waste through closed-loop recycling of materials.

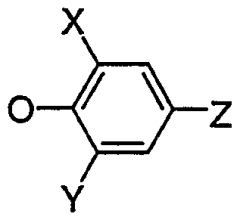

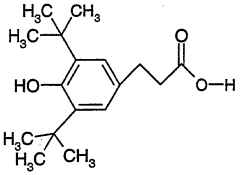

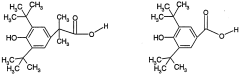

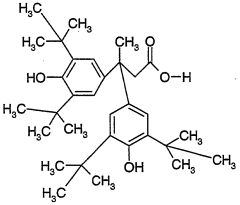

Mixtures containing isocyanate and stabilisers of the hindered phenol type with a high molecular weight

PatentWO2004111119A1

Innovation

- Development of mixtures containing isocyanate and amorphous or liquid stabilizers with specific molecular weight ranges and structures, linked via polyols, which are non-volatile and easy to incorporate, using phenolic groups connected via ester or amide groups, and optimized with phosphorus compounds to prevent crystallization and enhance compatibility.

Environmental Impact Assessment of Isocyanates

The environmental impact assessment of isocyanates is a critical component in implementing sustainability initiatives for these widely used chemical compounds. Isocyanates, primarily used in the production of polyurethanes, have significant environmental implications throughout their lifecycle, from production to disposal.

In the manufacturing process, isocyanates pose potential risks to air and water quality. Emissions of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) are primary concerns. These emissions can contribute to smog formation and have adverse effects on local ecosystems. Additionally, the production of isocyanates often involves the use of phosgene, a highly toxic substance, which requires stringent safety measures to prevent environmental contamination.

Water pollution is another key consideration in the environmental impact of isocyanates. Improper handling or disposal can lead to contamination of water bodies, potentially harming aquatic life and compromising water quality for human use. The persistence of isocyanate-derived compounds in the environment further exacerbates these concerns, as they may bioaccumulate in the food chain.

The use phase of isocyanate-containing products also contributes to their environmental footprint. Many polyurethane products, such as foams and coatings, can release small amounts of unreacted isocyanates over time. This slow emission can impact indoor air quality and potentially affect human health, particularly in poorly ventilated spaces.

End-of-life management of isocyanate-based products presents additional environmental challenges. Many polyurethane products are not easily recyclable, leading to increased waste in landfills. Incineration, while sometimes used as a disposal method, can release toxic fumes if not properly controlled, potentially contributing to air pollution and greenhouse gas emissions.

To mitigate these environmental impacts, several strategies can be employed. Implementing closed-loop production systems can significantly reduce emissions and waste during manufacturing. Developing safer alternatives to phosgene in isocyanate production can decrease the risk of severe environmental contamination. Improving product formulations to minimize unreacted isocyanates can enhance the safety of end-use products.

Furthermore, advancing recycling technologies for polyurethane products can help reduce waste and promote a more circular economy. Research into biodegradable alternatives and bio-based isocyanates offers promising avenues for reducing the long-term environmental impact of these materials.

In the manufacturing process, isocyanates pose potential risks to air and water quality. Emissions of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) are primary concerns. These emissions can contribute to smog formation and have adverse effects on local ecosystems. Additionally, the production of isocyanates often involves the use of phosgene, a highly toxic substance, which requires stringent safety measures to prevent environmental contamination.

Water pollution is another key consideration in the environmental impact of isocyanates. Improper handling or disposal can lead to contamination of water bodies, potentially harming aquatic life and compromising water quality for human use. The persistence of isocyanate-derived compounds in the environment further exacerbates these concerns, as they may bioaccumulate in the food chain.

The use phase of isocyanate-containing products also contributes to their environmental footprint. Many polyurethane products, such as foams and coatings, can release small amounts of unreacted isocyanates over time. This slow emission can impact indoor air quality and potentially affect human health, particularly in poorly ventilated spaces.

End-of-life management of isocyanate-based products presents additional environmental challenges. Many polyurethane products are not easily recyclable, leading to increased waste in landfills. Incineration, while sometimes used as a disposal method, can release toxic fumes if not properly controlled, potentially contributing to air pollution and greenhouse gas emissions.

To mitigate these environmental impacts, several strategies can be employed. Implementing closed-loop production systems can significantly reduce emissions and waste during manufacturing. Developing safer alternatives to phosgene in isocyanate production can decrease the risk of severe environmental contamination. Improving product formulations to minimize unreacted isocyanates can enhance the safety of end-use products.

Furthermore, advancing recycling technologies for polyurethane products can help reduce waste and promote a more circular economy. Research into biodegradable alternatives and bio-based isocyanates offers promising avenues for reducing the long-term environmental impact of these materials.

Regulatory Framework for Isocyanate Use

The regulatory framework for isocyanate use is a critical component in implementing sustainable practices within the industry. Governments and international organizations have established comprehensive guidelines to ensure the safe handling, storage, and disposal of isocyanates, as well as to minimize their environmental impact.

In the United States, the Occupational Safety and Health Administration (OSHA) has set stringent standards for isocyanate exposure in the workplace. These regulations mandate the use of personal protective equipment, proper ventilation systems, and regular health monitoring for workers exposed to isocyanates. The Environmental Protection Agency (EPA) also regulates isocyanate emissions under the Clean Air Act, requiring facilities to implement control technologies and report their emissions.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to isocyanates and their derivatives. This framework requires manufacturers and importers to register chemicals, assess their hazards, and communicate safety information to users. Additionally, the EU has specific directives on worker protection and environmental safety that directly impact isocyanate use.

In Asia, countries like China and Japan have developed their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances requires manufacturers to register new isocyanate-based products and provide safety data. Japan's Chemical Substances Control Law similarly regulates the manufacture, import, and use of isocyanates.

International organizations, such as the International Labor Organization (ILO), have established guidelines for the safe use of isocyanates in various industries. These guidelines often serve as a basis for national regulations and industry best practices.

Many countries have also implemented product stewardship programs, encouraging manufacturers to take responsibility for the entire lifecycle of their isocyanate products. These programs often include requirements for proper labeling, safe transportation, and end-of-life management.

The regulatory landscape for isocyanates is continually evolving, with a trend towards stricter controls and increased focus on sustainability. Recent developments include the push for alternatives to certain isocyanates, particularly those classified as substances of very high concern (SVHCs) under REACH.

Compliance with these regulations is essential for companies implementing isocyanate sustainability initiatives. It not only ensures legal operation but also demonstrates commitment to environmental stewardship and worker safety. Companies must stay informed about regulatory changes and proactively adapt their practices to meet or exceed regulatory requirements.

In the United States, the Occupational Safety and Health Administration (OSHA) has set stringent standards for isocyanate exposure in the workplace. These regulations mandate the use of personal protective equipment, proper ventilation systems, and regular health monitoring for workers exposed to isocyanates. The Environmental Protection Agency (EPA) also regulates isocyanate emissions under the Clean Air Act, requiring facilities to implement control technologies and report their emissions.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to isocyanates and their derivatives. This framework requires manufacturers and importers to register chemicals, assess their hazards, and communicate safety information to users. Additionally, the EU has specific directives on worker protection and environmental safety that directly impact isocyanate use.

In Asia, countries like China and Japan have developed their own regulatory frameworks. China's Measures for Environmental Management of New Chemical Substances requires manufacturers to register new isocyanate-based products and provide safety data. Japan's Chemical Substances Control Law similarly regulates the manufacture, import, and use of isocyanates.

International organizations, such as the International Labor Organization (ILO), have established guidelines for the safe use of isocyanates in various industries. These guidelines often serve as a basis for national regulations and industry best practices.

Many countries have also implemented product stewardship programs, encouraging manufacturers to take responsibility for the entire lifecycle of their isocyanate products. These programs often include requirements for proper labeling, safe transportation, and end-of-life management.

The regulatory landscape for isocyanates is continually evolving, with a trend towards stricter controls and increased focus on sustainability. Recent developments include the push for alternatives to certain isocyanates, particularly those classified as substances of very high concern (SVHCs) under REACH.

Compliance with these regulations is essential for companies implementing isocyanate sustainability initiatives. It not only ensures legal operation but also demonstrates commitment to environmental stewardship and worker safety. Companies must stay informed about regulatory changes and proactively adapt their practices to meet or exceed regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!