Industry Best Practices for Isocyanate Waste Management

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Waste Management Background and Objectives

Isocyanate waste management has become a critical concern in various industries due to the potential environmental and health hazards associated with these compounds. The evolution of isocyanate waste management practices can be traced back to the mid-20th century when the widespread use of polyurethanes in manufacturing began. Initially, the focus was primarily on production efficiency, with limited consideration for waste disposal. However, as awareness of the toxic nature of isocyanates grew, regulatory bodies started implementing stricter guidelines for their handling and disposal.

The technological progression in isocyanate waste management has been driven by a combination of regulatory pressures, environmental concerns, and industry initiatives. Early methods often involved simple containment and landfill disposal, which proved inadequate due to the reactive nature of isocyanates. This led to the development of more sophisticated treatment techniques, including chemical neutralization, incineration, and advanced oxidation processes.

Current objectives in isocyanate waste management center around minimizing environmental impact, ensuring worker safety, and optimizing resource utilization. Key goals include reducing the volume of waste generated, developing more efficient treatment technologies, and exploring possibilities for recycling or repurposing isocyanate-containing materials. There is also a growing emphasis on implementing circular economy principles within the isocyanate lifecycle.

The industry is now moving towards integrated waste management systems that address the entire lifecycle of isocyanate-containing products. This holistic approach encompasses everything from raw material selection and process optimization to end-of-life product management. Advanced monitoring and control systems are being developed to enhance the efficiency and safety of waste treatment processes, while research is ongoing into novel degradation pathways and bio-based alternatives to traditional isocyanates.

Globally, there is a trend towards harmonizing isocyanate waste management practices, driven by international agreements and the need for consistent standards across supply chains. This has led to increased collaboration between industry players, research institutions, and regulatory bodies to develop best practices and innovative solutions. The future of isocyanate waste management is likely to see further integration of digital technologies, such as AI and IoT, to optimize waste treatment processes and enable real-time monitoring of environmental impacts.

As the industry continues to evolve, the objectives for isocyanate waste management are expanding to include not only compliance and risk mitigation but also value creation through waste valorization and the development of more sustainable production processes. This shift represents a significant opportunity for technological innovation and the emergence of new business models within the sector.

The technological progression in isocyanate waste management has been driven by a combination of regulatory pressures, environmental concerns, and industry initiatives. Early methods often involved simple containment and landfill disposal, which proved inadequate due to the reactive nature of isocyanates. This led to the development of more sophisticated treatment techniques, including chemical neutralization, incineration, and advanced oxidation processes.

Current objectives in isocyanate waste management center around minimizing environmental impact, ensuring worker safety, and optimizing resource utilization. Key goals include reducing the volume of waste generated, developing more efficient treatment technologies, and exploring possibilities for recycling or repurposing isocyanate-containing materials. There is also a growing emphasis on implementing circular economy principles within the isocyanate lifecycle.

The industry is now moving towards integrated waste management systems that address the entire lifecycle of isocyanate-containing products. This holistic approach encompasses everything from raw material selection and process optimization to end-of-life product management. Advanced monitoring and control systems are being developed to enhance the efficiency and safety of waste treatment processes, while research is ongoing into novel degradation pathways and bio-based alternatives to traditional isocyanates.

Globally, there is a trend towards harmonizing isocyanate waste management practices, driven by international agreements and the need for consistent standards across supply chains. This has led to increased collaboration between industry players, research institutions, and regulatory bodies to develop best practices and innovative solutions. The future of isocyanate waste management is likely to see further integration of digital technologies, such as AI and IoT, to optimize waste treatment processes and enable real-time monitoring of environmental impacts.

As the industry continues to evolve, the objectives for isocyanate waste management are expanding to include not only compliance and risk mitigation but also value creation through waste valorization and the development of more sustainable production processes. This shift represents a significant opportunity for technological innovation and the emergence of new business models within the sector.

Market Demand for Sustainable Isocyanate Disposal

The market demand for sustainable isocyanate disposal has been steadily increasing in recent years, driven by stringent environmental regulations, growing awareness of health hazards, and the push for more sustainable industrial practices. Isocyanates, widely used in the production of polyurethanes, adhesives, and coatings, pose significant environmental and health risks if not properly managed.

Environmental concerns have become a major driver for sustainable isocyanate disposal solutions. As governments worldwide implement stricter regulations on chemical waste management, industries are compelled to adopt more environmentally friendly disposal methods. This regulatory pressure has created a substantial market for innovative disposal technologies that can effectively neutralize or recycle isocyanate waste.

The health risks associated with isocyanate exposure have also contributed to the growing demand for better disposal practices. Isocyanates are known respiratory sensitizers and can cause severe health issues with prolonged exposure. This has led to increased pressure from workers' unions and safety organizations for improved handling and disposal methods, further expanding the market for sustainable solutions.

In the manufacturing sector, there is a rising demand for closed-loop systems that can recycle or repurpose isocyanate waste. Companies are increasingly looking for ways to reduce their environmental footprint and cut costs associated with waste disposal. This has created opportunities for technologies that can recover and reuse isocyanates, turning waste management into a potential source of cost savings and improved efficiency.

The construction industry, a major consumer of isocyanate-based products, is also driving demand for sustainable disposal solutions. With the growth of green building practices, there is an increasing need for environmentally responsible ways to handle isocyanate-containing materials during construction and demolition processes.

Emerging markets, particularly in Asia and South America, are showing significant potential for growth in sustainable isocyanate disposal. As these regions industrialize and adopt more stringent environmental standards, the demand for advanced waste management solutions is expected to rise sharply.

The automotive industry, another significant user of isocyanate-based products, is also contributing to the market demand. As vehicle manufacturers strive to meet sustainability goals and comply with end-of-life vehicle regulations, there is a growing need for solutions that can safely dispose of or recycle isocyanate-containing components.

Overall, the market for sustainable isocyanate disposal is characterized by a strong growth trajectory, driven by a combination of regulatory pressures, health concerns, cost-saving opportunities, and the global shift towards more sustainable industrial practices. This trend is expected to continue, creating significant opportunities for companies that can provide effective, environmentally friendly solutions for isocyanate waste management.

Environmental concerns have become a major driver for sustainable isocyanate disposal solutions. As governments worldwide implement stricter regulations on chemical waste management, industries are compelled to adopt more environmentally friendly disposal methods. This regulatory pressure has created a substantial market for innovative disposal technologies that can effectively neutralize or recycle isocyanate waste.

The health risks associated with isocyanate exposure have also contributed to the growing demand for better disposal practices. Isocyanates are known respiratory sensitizers and can cause severe health issues with prolonged exposure. This has led to increased pressure from workers' unions and safety organizations for improved handling and disposal methods, further expanding the market for sustainable solutions.

In the manufacturing sector, there is a rising demand for closed-loop systems that can recycle or repurpose isocyanate waste. Companies are increasingly looking for ways to reduce their environmental footprint and cut costs associated with waste disposal. This has created opportunities for technologies that can recover and reuse isocyanates, turning waste management into a potential source of cost savings and improved efficiency.

The construction industry, a major consumer of isocyanate-based products, is also driving demand for sustainable disposal solutions. With the growth of green building practices, there is an increasing need for environmentally responsible ways to handle isocyanate-containing materials during construction and demolition processes.

Emerging markets, particularly in Asia and South America, are showing significant potential for growth in sustainable isocyanate disposal. As these regions industrialize and adopt more stringent environmental standards, the demand for advanced waste management solutions is expected to rise sharply.

The automotive industry, another significant user of isocyanate-based products, is also contributing to the market demand. As vehicle manufacturers strive to meet sustainability goals and comply with end-of-life vehicle regulations, there is a growing need for solutions that can safely dispose of or recycle isocyanate-containing components.

Overall, the market for sustainable isocyanate disposal is characterized by a strong growth trajectory, driven by a combination of regulatory pressures, health concerns, cost-saving opportunities, and the global shift towards more sustainable industrial practices. This trend is expected to continue, creating significant opportunities for companies that can provide effective, environmentally friendly solutions for isocyanate waste management.

Current Challenges in Isocyanate Waste Handling

The management of isocyanate waste presents several significant challenges in the current industrial landscape. One of the primary issues is the highly reactive nature of isocyanates, which can pose serious health and environmental risks if not handled properly. Exposure to isocyanates can cause respiratory irritation, skin sensitization, and in severe cases, asthma-like reactions. This reactivity also makes isocyanate waste difficult to store and transport safely, requiring specialized containment and handling procedures.

Another major challenge is the complexity of isocyanate waste streams. Many industrial processes that use isocyanates generate waste that contains a mixture of unreacted isocyanates, partially reacted products, and other chemical compounds. This heterogeneity complicates treatment and disposal methods, as different components may require different handling approaches. Additionally, the presence of catalysts and other additives in isocyanate formulations can further complicate waste management strategies.

The regulatory landscape surrounding isocyanate waste handling is increasingly stringent, posing compliance challenges for many industries. Environmental regulations, such as the Resource Conservation and Recovery Act (RCRA) in the United States, classify many isocyanate wastes as hazardous, requiring specific disposal methods and documentation. Compliance with these regulations often necessitates significant investments in waste management infrastructure and training, which can be particularly burdensome for smaller businesses.

The disposal of isocyanate waste also presents technical challenges. Traditional methods like incineration can be effective but are energy-intensive and may produce harmful emissions if not properly controlled. Alternative disposal methods, such as chemical neutralization or biodegradation, are being explored but often face limitations in scalability or effectiveness for all types of isocyanate waste.

Recycling and recovery of isocyanates from waste streams is an area of growing interest but faces significant technical hurdles. The chemical instability of isocyanates and the presence of contaminants in waste streams make it difficult to recover pure, reusable isocyanates cost-effectively. Developing economically viable recycling processes that can handle the variability in isocyanate waste composition remains a challenge for the industry.

Lastly, there is a growing need for more sustainable waste management practices in the isocyanate industry. This includes not only improving end-of-life waste handling but also implementing strategies to reduce waste generation at the source. Balancing these sustainability goals with the practical and economic realities of industrial production represents an ongoing challenge for manufacturers and waste management professionals alike.

Another major challenge is the complexity of isocyanate waste streams. Many industrial processes that use isocyanates generate waste that contains a mixture of unreacted isocyanates, partially reacted products, and other chemical compounds. This heterogeneity complicates treatment and disposal methods, as different components may require different handling approaches. Additionally, the presence of catalysts and other additives in isocyanate formulations can further complicate waste management strategies.

The regulatory landscape surrounding isocyanate waste handling is increasingly stringent, posing compliance challenges for many industries. Environmental regulations, such as the Resource Conservation and Recovery Act (RCRA) in the United States, classify many isocyanate wastes as hazardous, requiring specific disposal methods and documentation. Compliance with these regulations often necessitates significant investments in waste management infrastructure and training, which can be particularly burdensome for smaller businesses.

The disposal of isocyanate waste also presents technical challenges. Traditional methods like incineration can be effective but are energy-intensive and may produce harmful emissions if not properly controlled. Alternative disposal methods, such as chemical neutralization or biodegradation, are being explored but often face limitations in scalability or effectiveness for all types of isocyanate waste.

Recycling and recovery of isocyanates from waste streams is an area of growing interest but faces significant technical hurdles. The chemical instability of isocyanates and the presence of contaminants in waste streams make it difficult to recover pure, reusable isocyanates cost-effectively. Developing economically viable recycling processes that can handle the variability in isocyanate waste composition remains a challenge for the industry.

Lastly, there is a growing need for more sustainable waste management practices in the isocyanate industry. This includes not only improving end-of-life waste handling but also implementing strategies to reduce waste generation at the source. Balancing these sustainability goals with the practical and economic realities of industrial production represents an ongoing challenge for manufacturers and waste management professionals alike.

Existing Best Practices for Isocyanate Waste Disposal

01 Chemical treatment of isocyanate waste

Various chemical methods are employed to treat isocyanate waste, including neutralization, hydrolysis, and oxidation. These processes aim to convert hazardous isocyanates into less harmful compounds, reducing environmental and health risks associated with their disposal.- Chemical treatment of isocyanate waste: Various chemical methods are employed to treat isocyanate waste, including neutralization, hydrolysis, and oxidation. These processes aim to convert hazardous isocyanates into less harmful compounds, reducing environmental and health risks associated with their disposal.

- Recycling and recovery of isocyanate waste: Techniques for recycling and recovering isocyanate waste involve separating useful components and reprocessing them for reuse in manufacturing processes. This approach minimizes waste generation and promotes resource efficiency in industrial applications of isocyanates.

- Incineration and thermal treatment: High-temperature incineration and thermal treatment methods are used to destroy isocyanate waste. These processes involve controlled combustion under specific conditions to ensure complete decomposition of hazardous compounds, with proper emission control systems in place.

- Biological treatment of isocyanate waste: Biological treatment methods utilize microorganisms to degrade isocyanate compounds. This eco-friendly approach involves the use of specialized bacteria or enzymes to break down isocyanates into less harmful substances, potentially in combination with other treatment methods.

- Containment and storage solutions: Proper containment and storage solutions are crucial for managing isocyanate waste before treatment or disposal. This includes the use of specialized containers, storage facilities, and handling procedures to prevent leaks, spills, and exposure risks associated with isocyanate compounds.

02 Recycling and recovery of isocyanate waste

Techniques for recycling and recovering isocyanate waste involve separating and purifying the components for reuse in manufacturing processes. This approach minimizes waste generation and promotes resource efficiency in industrial applications of isocyanates.Expand Specific Solutions03 Incineration and thermal treatment

High-temperature incineration and thermal treatment methods are used to destroy isocyanate waste. These processes involve controlled combustion under specific conditions to ensure complete decomposition of the hazardous compounds, often with energy recovery systems in place.Expand Specific Solutions04 Biological treatment of isocyanate waste

Biological treatment methods utilize microorganisms to degrade isocyanate compounds. This eco-friendly approach involves the use of specialized bacteria or enzymes to break down the waste into less harmful substances, often in controlled bioreactor environments.Expand Specific Solutions05 Containment and storage solutions

Proper containment and storage solutions are crucial for managing isocyanate waste before treatment or disposal. This includes the use of specialized containers, storage facilities, and handling procedures to prevent leaks, spills, and exposure risks during the waste management process.Expand Specific Solutions

Key Players in Isocyanate Waste Management Industry

The industry for isocyanate waste management is in a mature stage, with established best practices and regulations in place. The market size is significant, driven by the widespread use of isocyanates in various industries. Technologically, the field is well-developed, with major players like BASF, Covestro, and Wanhua Chemical Group leading innovation. These companies have advanced waste management systems and are continually improving their processes. Smaller specialized firms like Changchun Gold Research Institute and China City Environment Protection Engineering Ltd. Co. are also contributing to technological advancements, focusing on specific aspects of isocyanate waste treatment and recycling.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals has developed an integrated isocyanate waste management system that combines several innovative technologies. Their approach includes a proprietary catalytic hydrolysis process that efficiently breaks down isocyanate waste into less hazardous compounds[17]. This is complemented by an advanced adsorption system using specially engineered nanomaterials to capture and concentrate isocyanate residues from waste streams[19]. Mitsui has also implemented a novel plasma treatment technology for destroying complex isocyanate molecules in gaseous emissions[21]. Additionally, the company has developed a green chemistry approach to synthesize isocyanates, which significantly reduces waste generation in the production process[23].

Strengths: Diverse range of treatment technologies; Advanced materials science applications; Focus on reducing waste at the source. Weaknesses: Some technologies may be at early stages of industrial implementation; Potential high capital costs for full system integration.

Covestro Deutschland AG

Technical Solution: Covestro has pioneered a circular economy approach to isocyanate waste management. Their system focuses on chemical recycling of polyurethane foam waste, which is a major source of isocyanate-containing materials[2]. The process involves breaking down the foam into its original chemical components, including recovering isocyanates for reuse[4]. Covestro has also developed a novel catalytic process that can convert isocyanate waste into valuable diamines, which can be used as raw materials in various industries[6]. Furthermore, the company has implemented an advanced wastewater treatment system specifically designed to handle isocyanate-contaminated water, ensuring minimal environmental impact[8].

Strengths: Chemical recycling enables high-quality material recovery; Conversion of waste into valuable products; Specialized wastewater treatment. Weaknesses: Process complexity may limit widespread adoption; Requires consistent waste input for efficiency.

Innovative Approaches in Isocyanate Waste Recycling

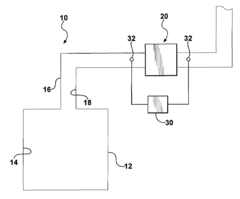

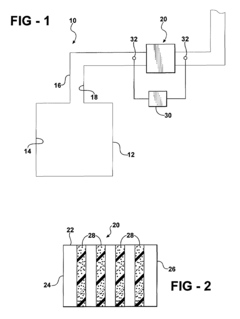

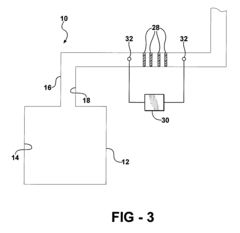

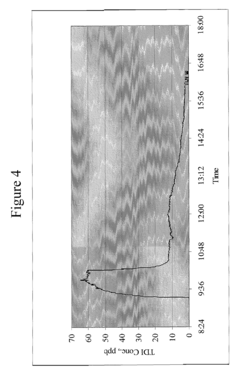

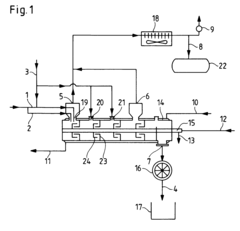

Apparatus for removing vaporized unreacted isocyanate from a gaseous waste stream

PatentInactiveUS7431907B2

Innovation

- A medium formed from the reaction product of an isocyanate component and an isocyanate-reactive component with free isocyanate-reactive groups, which reacts with vaporized unreacted isocyanate to produce a gaseous product stream substantially free of unreacted isocyanate, eliminating the need for high pressures and allowing for lighter, less bulky designs.

Process for preparing isocyanates and continuous treatment of the residue

PatentInactiveEP0626368A1

Innovation

- A process involving continuous distillation of the residue with high-boiling hydrocarbons, such as bitumen, under specific temperature and pressure conditions to separate and discharge the residue as free-flowing granules, effectively removing isocyanate and chlorine-containing impurities, and utilizing a heated, paddle vacuum dryer for further processing.

Environmental Regulations for Isocyanate Waste

Environmental regulations for isocyanate waste management have become increasingly stringent in recent years due to the potential hazards associated with these chemicals. Isocyanates are widely used in the production of polyurethanes, which are found in various industries including automotive, construction, and furniture manufacturing. The primary concern with isocyanate waste is its potential to cause severe health and environmental impacts if not properly handled and disposed of.

In the United States, the Environmental Protection Agency (EPA) regulates isocyanate waste under the Resource Conservation and Recovery Act (RCRA). Isocyanate waste is classified as hazardous waste due to its reactivity and toxicity. Facilities generating isocyanate waste must comply with strict storage, handling, and disposal requirements. This includes proper labeling, use of appropriate containers, and maintaining detailed records of waste generation and disposal.

The Occupational Safety and Health Administration (OSHA) has also established regulations to protect workers from exposure to isocyanates. These regulations mandate the use of personal protective equipment, implementation of engineering controls, and regular monitoring of workplace air quality. Employers are required to provide comprehensive training to employees on the safe handling of isocyanates and proper waste management procedures.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use and disposal of isocyanates. REACH requires manufacturers and importers to register chemicals and provide detailed information on their properties, risks, and safe use. The regulation also imposes restrictions on certain hazardous substances, including some isocyanates, to minimize their environmental impact.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which provides a standardized approach to communicating chemical hazards. Under GHS, isocyanates are classified as respiratory sensitizers and must be labeled with appropriate hazard pictograms and statements.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal regulates the international transport of hazardous waste, including isocyanate waste. Signatory countries must obtain prior informed consent before shipping hazardous waste across borders, ensuring proper handling and disposal at the destination.

As environmental concerns continue to grow, regulations surrounding isocyanate waste management are likely to become more stringent. Industry stakeholders must stay informed about evolving regulations and invest in innovative technologies and practices to minimize waste generation and improve disposal methods. Compliance with these regulations not only ensures environmental protection but also helps companies avoid costly penalties and maintain their reputation in an increasingly environmentally conscious market.

In the United States, the Environmental Protection Agency (EPA) regulates isocyanate waste under the Resource Conservation and Recovery Act (RCRA). Isocyanate waste is classified as hazardous waste due to its reactivity and toxicity. Facilities generating isocyanate waste must comply with strict storage, handling, and disposal requirements. This includes proper labeling, use of appropriate containers, and maintaining detailed records of waste generation and disposal.

The Occupational Safety and Health Administration (OSHA) has also established regulations to protect workers from exposure to isocyanates. These regulations mandate the use of personal protective equipment, implementation of engineering controls, and regular monitoring of workplace air quality. Employers are required to provide comprehensive training to employees on the safe handling of isocyanates and proper waste management procedures.

In the European Union, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use and disposal of isocyanates. REACH requires manufacturers and importers to register chemicals and provide detailed information on their properties, risks, and safe use. The regulation also imposes restrictions on certain hazardous substances, including some isocyanates, to minimize their environmental impact.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which provides a standardized approach to communicating chemical hazards. Under GHS, isocyanates are classified as respiratory sensitizers and must be labeled with appropriate hazard pictograms and statements.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal regulates the international transport of hazardous waste, including isocyanate waste. Signatory countries must obtain prior informed consent before shipping hazardous waste across borders, ensuring proper handling and disposal at the destination.

As environmental concerns continue to grow, regulations surrounding isocyanate waste management are likely to become more stringent. Industry stakeholders must stay informed about evolving regulations and invest in innovative technologies and practices to minimize waste generation and improve disposal methods. Compliance with these regulations not only ensures environmental protection but also helps companies avoid costly penalties and maintain their reputation in an increasingly environmentally conscious market.

Health and Safety Considerations in Waste Management

Health and safety considerations are paramount in isocyanate waste management due to the hazardous nature of these chemicals. Isocyanates are highly reactive compounds that can cause severe respiratory issues, skin irritation, and other health problems if not handled properly. To ensure the safety of workers and the environment, strict protocols must be implemented throughout the waste management process.

Personal protective equipment (PPE) is crucial when dealing with isocyanate waste. Workers should wear appropriate respiratory protection, such as supplied air respirators or self-contained breathing apparatus, depending on the concentration levels and exposure risks. Chemical-resistant gloves, protective clothing, and eye protection are also essential to prevent skin contact and potential absorption.

Proper ventilation is critical in areas where isocyanate waste is handled or stored. Adequate air exchange rates and local exhaust ventilation systems help minimize airborne concentrations of isocyanates, reducing the risk of inhalation exposure. Regular air monitoring should be conducted to ensure that exposure levels remain below permissible limits.

Training and education play a vital role in maintaining a safe work environment. All personnel involved in isocyanate waste management should receive comprehensive training on the hazards associated with these chemicals, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses and safety drills help reinforce best practices and keep workers prepared for potential incidents.

Spill response procedures must be well-established and regularly practiced. Quick and effective containment of isocyanate spills is crucial to prevent environmental contamination and minimize exposure risks. Spill kits specifically designed for isocyanates should be readily available, and workers should be trained in their proper use.

Medical surveillance programs are recommended for workers regularly exposed to isocyanates. These programs may include baseline and periodic health assessments, pulmonary function tests, and skin examinations to detect any early signs of adverse health effects related to isocyanate exposure.

Proper storage and segregation of isocyanate waste are essential to prevent accidental reactions. Isocyanates should be stored in cool, dry areas away from incompatible materials, heat sources, and direct sunlight. Containers should be properly labeled and inspected regularly for signs of damage or leakage.

Emergency response plans must be in place to address potential incidents involving isocyanate waste. These plans should outline evacuation procedures, decontamination protocols, and steps for notifying appropriate authorities. Regular drills and simulations help ensure that all personnel are familiar with emergency procedures and can respond effectively in case of an incident.

By prioritizing these health and safety considerations, organizations can significantly reduce the risks associated with isocyanate waste management and create a safer working environment for their employees while protecting the surrounding community and ecosystem.

Personal protective equipment (PPE) is crucial when dealing with isocyanate waste. Workers should wear appropriate respiratory protection, such as supplied air respirators or self-contained breathing apparatus, depending on the concentration levels and exposure risks. Chemical-resistant gloves, protective clothing, and eye protection are also essential to prevent skin contact and potential absorption.

Proper ventilation is critical in areas where isocyanate waste is handled or stored. Adequate air exchange rates and local exhaust ventilation systems help minimize airborne concentrations of isocyanates, reducing the risk of inhalation exposure. Regular air monitoring should be conducted to ensure that exposure levels remain below permissible limits.

Training and education play a vital role in maintaining a safe work environment. All personnel involved in isocyanate waste management should receive comprehensive training on the hazards associated with these chemicals, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses and safety drills help reinforce best practices and keep workers prepared for potential incidents.

Spill response procedures must be well-established and regularly practiced. Quick and effective containment of isocyanate spills is crucial to prevent environmental contamination and minimize exposure risks. Spill kits specifically designed for isocyanates should be readily available, and workers should be trained in their proper use.

Medical surveillance programs are recommended for workers regularly exposed to isocyanates. These programs may include baseline and periodic health assessments, pulmonary function tests, and skin examinations to detect any early signs of adverse health effects related to isocyanate exposure.

Proper storage and segregation of isocyanate waste are essential to prevent accidental reactions. Isocyanates should be stored in cool, dry areas away from incompatible materials, heat sources, and direct sunlight. Containers should be properly labeled and inspected regularly for signs of damage or leakage.

Emergency response plans must be in place to address potential incidents involving isocyanate waste. These plans should outline evacuation procedures, decontamination protocols, and steps for notifying appropriate authorities. Regular drills and simulations help ensure that all personnel are familiar with emergency procedures and can respond effectively in case of an incident.

By prioritizing these health and safety considerations, organizations can significantly reduce the risks associated with isocyanate waste management and create a safer working environment for their employees while protecting the surrounding community and ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!