Isocyanate Applications in Automotive Manufacturing

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Tech Evolution

The evolution of isocyanate technology in automotive manufacturing has been marked by significant advancements and innovations over the past several decades. Initially introduced in the 1930s, isocyanates quickly gained traction in the automotive industry due to their versatile properties and ability to form polyurethanes.

In the 1950s and 1960s, the use of isocyanates in automotive applications expanded rapidly, particularly in the production of flexible foam for seating and interior components. This period saw the development of more efficient production methods and the introduction of new isocyanate formulations tailored specifically for automotive needs.

The 1970s and 1980s witnessed a shift towards more environmentally friendly and energy-efficient manufacturing processes. This led to the development of low-density, high-performance polyurethane foams that reduced vehicle weight and improved fuel efficiency. Concurrently, advancements in isocyanate chemistry enabled the creation of more durable and weather-resistant coatings for automotive exteriors.

The 1990s brought about a focus on safety and emissions reduction. Manufacturers began exploring alternatives to traditional isocyanates, such as water-based systems and blocked isocyanates, to minimize volatile organic compound (VOC) emissions during production and improve worker safety.

In the early 2000s, the automotive industry saw a surge in the use of reaction injection molding (RIM) techniques utilizing isocyanate-based materials. This technology allowed for the production of large, complex parts with excellent surface finish and dimensional stability, revolutionizing the manufacturing of bumpers, body panels, and other exterior components.

Recent years have seen a push towards sustainability and bio-based materials. Research efforts have focused on developing isocyanates derived from renewable resources, such as plant-based polyols, to reduce the industry's reliance on petroleum-based raw materials.

The latest technological advancements in isocyanate applications for automotive manufacturing include the development of self-healing polyurethane coatings, which can repair minor scratches and damages autonomously. Additionally, progress has been made in creating isocyanate-free alternatives that maintain similar performance characteristics, addressing ongoing health and environmental concerns.

Looking ahead, the evolution of isocyanate technology in automotive manufacturing is likely to continue focusing on sustainability, performance enhancement, and cost-effectiveness. Emerging trends include the integration of nanotechnology to improve material properties, the development of smart polyurethanes with embedded sensors for real-time monitoring, and the exploration of additive manufacturing techniques using isocyanate-based materials for rapid prototyping and customization in automotive production.

In the 1950s and 1960s, the use of isocyanates in automotive applications expanded rapidly, particularly in the production of flexible foam for seating and interior components. This period saw the development of more efficient production methods and the introduction of new isocyanate formulations tailored specifically for automotive needs.

The 1970s and 1980s witnessed a shift towards more environmentally friendly and energy-efficient manufacturing processes. This led to the development of low-density, high-performance polyurethane foams that reduced vehicle weight and improved fuel efficiency. Concurrently, advancements in isocyanate chemistry enabled the creation of more durable and weather-resistant coatings for automotive exteriors.

The 1990s brought about a focus on safety and emissions reduction. Manufacturers began exploring alternatives to traditional isocyanates, such as water-based systems and blocked isocyanates, to minimize volatile organic compound (VOC) emissions during production and improve worker safety.

In the early 2000s, the automotive industry saw a surge in the use of reaction injection molding (RIM) techniques utilizing isocyanate-based materials. This technology allowed for the production of large, complex parts with excellent surface finish and dimensional stability, revolutionizing the manufacturing of bumpers, body panels, and other exterior components.

Recent years have seen a push towards sustainability and bio-based materials. Research efforts have focused on developing isocyanates derived from renewable resources, such as plant-based polyols, to reduce the industry's reliance on petroleum-based raw materials.

The latest technological advancements in isocyanate applications for automotive manufacturing include the development of self-healing polyurethane coatings, which can repair minor scratches and damages autonomously. Additionally, progress has been made in creating isocyanate-free alternatives that maintain similar performance characteristics, addressing ongoing health and environmental concerns.

Looking ahead, the evolution of isocyanate technology in automotive manufacturing is likely to continue focusing on sustainability, performance enhancement, and cost-effectiveness. Emerging trends include the integration of nanotechnology to improve material properties, the development of smart polyurethanes with embedded sensors for real-time monitoring, and the exploration of additive manufacturing techniques using isocyanate-based materials for rapid prototyping and customization in automotive production.

Automotive Market Demand

The automotive industry has been experiencing significant growth and transformation in recent years, driving the demand for isocyanate applications in manufacturing processes. As vehicle production continues to rise globally, the need for lightweight materials and advanced coatings has become increasingly important. Isocyanates play a crucial role in meeting these demands, particularly in the production of polyurethane-based components and finishes.

The market for isocyanate applications in automotive manufacturing is primarily driven by the growing emphasis on fuel efficiency and environmental regulations. Automakers are constantly seeking ways to reduce vehicle weight without compromising safety or performance. Polyurethane foams, made using isocyanates, offer an excellent solution for lightweight seat cushions, headrests, and interior trim components. This trend is expected to continue as manufacturers strive to meet stringent fuel economy standards and reduce carbon emissions.

Another significant factor contributing to the demand for isocyanates in the automotive sector is the increasing focus on vehicle aesthetics and durability. Polyurethane coatings, which rely on isocyanates as a key ingredient, provide superior protection against corrosion, UV radiation, and chemical exposure. These coatings also offer excellent color retention and gloss, enhancing the overall appearance and longevity of vehicles. As consumer expectations for vehicle quality and appearance continue to rise, the demand for high-performance coatings is expected to grow accordingly.

The electric vehicle (EV) revolution is also influencing the demand for isocyanate applications in automotive manufacturing. As EV production ramps up, there is a growing need for specialized materials that can address the unique challenges of electric powertrains. Isocyanate-based materials are being developed to provide thermal management solutions, vibration dampening, and electrical insulation for EV components. This emerging market segment presents significant opportunities for isocyanate manufacturers and suppliers to the automotive industry.

In terms of regional demand, Asia-Pacific, particularly China and India, is expected to be the fastest-growing market for isocyanate applications in automotive manufacturing. The rapid expansion of the automotive industry in these countries, coupled with increasing disposable incomes and urbanization, is driving the demand for vehicles and, consequently, isocyanate-based products. North America and Europe, while more mature markets, continue to show steady demand growth, primarily driven by the shift towards electric and hybrid vehicles.

The automotive market demand for isocyanates is also influenced by advancements in manufacturing technologies. The adoption of robotics and automation in automotive production lines has led to increased precision in the application of isocyanate-based materials, resulting in improved quality and reduced waste. This trend is expected to continue, further driving the demand for specialized isocyanate formulations that are compatible with advanced manufacturing processes.

The market for isocyanate applications in automotive manufacturing is primarily driven by the growing emphasis on fuel efficiency and environmental regulations. Automakers are constantly seeking ways to reduce vehicle weight without compromising safety or performance. Polyurethane foams, made using isocyanates, offer an excellent solution for lightweight seat cushions, headrests, and interior trim components. This trend is expected to continue as manufacturers strive to meet stringent fuel economy standards and reduce carbon emissions.

Another significant factor contributing to the demand for isocyanates in the automotive sector is the increasing focus on vehicle aesthetics and durability. Polyurethane coatings, which rely on isocyanates as a key ingredient, provide superior protection against corrosion, UV radiation, and chemical exposure. These coatings also offer excellent color retention and gloss, enhancing the overall appearance and longevity of vehicles. As consumer expectations for vehicle quality and appearance continue to rise, the demand for high-performance coatings is expected to grow accordingly.

The electric vehicle (EV) revolution is also influencing the demand for isocyanate applications in automotive manufacturing. As EV production ramps up, there is a growing need for specialized materials that can address the unique challenges of electric powertrains. Isocyanate-based materials are being developed to provide thermal management solutions, vibration dampening, and electrical insulation for EV components. This emerging market segment presents significant opportunities for isocyanate manufacturers and suppliers to the automotive industry.

In terms of regional demand, Asia-Pacific, particularly China and India, is expected to be the fastest-growing market for isocyanate applications in automotive manufacturing. The rapid expansion of the automotive industry in these countries, coupled with increasing disposable incomes and urbanization, is driving the demand for vehicles and, consequently, isocyanate-based products. North America and Europe, while more mature markets, continue to show steady demand growth, primarily driven by the shift towards electric and hybrid vehicles.

The automotive market demand for isocyanates is also influenced by advancements in manufacturing technologies. The adoption of robotics and automation in automotive production lines has led to increased precision in the application of isocyanate-based materials, resulting in improved quality and reduced waste. This trend is expected to continue, further driving the demand for specialized isocyanate formulations that are compatible with advanced manufacturing processes.

Current Challenges

The automotive industry's reliance on isocyanates in manufacturing processes faces several significant challenges. One of the primary concerns is the health and safety risks associated with isocyanate exposure. These chemicals are known respiratory sensitizers and can cause severe allergic reactions, asthma, and other respiratory issues in workers who come into contact with them. Despite stringent safety protocols, ensuring complete protection for all personnel remains an ongoing challenge.

Environmental regulations pose another hurdle for isocyanate applications in automotive manufacturing. As global environmental standards become increasingly stringent, manufacturers must adapt their processes to reduce emissions and waste. This often requires substantial investments in new equipment and technologies, which can be financially burdensome for companies, especially smaller suppliers in the automotive supply chain.

The volatility of raw material prices for isocyanates presents a significant challenge for manufacturers. Fluctuations in the cost of key ingredients, such as toluene and propylene, can impact production costs and profit margins. This price instability makes long-term planning and budgeting difficult for automotive companies, potentially affecting their competitiveness in the market.

Another technical challenge lies in achieving consistent quality in isocyanate-based products, particularly in large-scale production environments. Factors such as temperature, humidity, and mixing ratios can significantly affect the final properties of polyurethane components. Maintaining precise control over these variables across different manufacturing locations and conditions is crucial but often challenging.

The automotive industry's shift towards more sustainable and eco-friendly materials presents a significant challenge for isocyanate applications. As consumers and regulators demand greener alternatives, manufacturers must explore bio-based or recycled content options for polyurethane components. However, developing these alternatives while maintaining the performance characteristics of traditional isocyanate-based materials remains a complex task.

Lastly, the increasing complexity of automotive designs and the demand for lighter vehicles to improve fuel efficiency create challenges for isocyanate applications. Engineers must constantly innovate to develop new formulations and processing techniques that can meet these evolving requirements while still leveraging the unique properties of isocyanate-based materials.

Environmental regulations pose another hurdle for isocyanate applications in automotive manufacturing. As global environmental standards become increasingly stringent, manufacturers must adapt their processes to reduce emissions and waste. This often requires substantial investments in new equipment and technologies, which can be financially burdensome for companies, especially smaller suppliers in the automotive supply chain.

The volatility of raw material prices for isocyanates presents a significant challenge for manufacturers. Fluctuations in the cost of key ingredients, such as toluene and propylene, can impact production costs and profit margins. This price instability makes long-term planning and budgeting difficult for automotive companies, potentially affecting their competitiveness in the market.

Another technical challenge lies in achieving consistent quality in isocyanate-based products, particularly in large-scale production environments. Factors such as temperature, humidity, and mixing ratios can significantly affect the final properties of polyurethane components. Maintaining precise control over these variables across different manufacturing locations and conditions is crucial but often challenging.

The automotive industry's shift towards more sustainable and eco-friendly materials presents a significant challenge for isocyanate applications. As consumers and regulators demand greener alternatives, manufacturers must explore bio-based or recycled content options for polyurethane components. However, developing these alternatives while maintaining the performance characteristics of traditional isocyanate-based materials remains a complex task.

Lastly, the increasing complexity of automotive designs and the demand for lighter vehicles to improve fuel efficiency create challenges for isocyanate applications. Engineers must constantly innovate to develop new formulations and processing techniques that can meet these evolving requirements while still leveraging the unique properties of isocyanate-based materials.

Isocyanate Solutions

01 Synthesis and properties of isocyanates

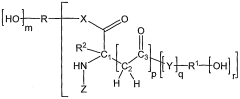

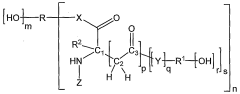

Isocyanates are a class of highly reactive compounds characterized by the -NCO functional group. They are widely used in the production of polyurethanes and other polymeric materials. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl compounds. Their properties, such as reactivity and stability, are crucial for various industrial applications.- Synthesis and properties of isocyanates: Isocyanates are a class of highly reactive compounds characterized by the -N=C=O functional group. They are widely used in the production of polyurethanes and other industrial applications. The synthesis of isocyanates often involves the reaction of amines with phosgene or other carbonyl-containing compounds. Their properties, such as reactivity and stability, are crucial for various applications in polymer chemistry and materials science.

- Applications of isocyanates in polyurethane production: Isocyanates play a crucial role in the production of polyurethanes, which are versatile polymers used in various industries. They react with polyols to form urethane linkages, creating materials with diverse properties. Applications include foam production, coatings, adhesives, and elastomers. The choice of isocyanate and polyol affects the final properties of the polyurethane product.

- Isocyanate-based coatings and adhesives: Isocyanates are essential components in the formulation of high-performance coatings and adhesives. They provide excellent adhesion, durability, and chemical resistance. These coatings and adhesives find applications in automotive, construction, and industrial sectors. The reactivity of isocyanates allows for rapid curing and the formation of strong bonds with various substrates.

- Safety and handling of isocyanates: Due to their high reactivity, isocyanates require careful handling and safety precautions. Exposure can cause respiratory irritation and sensitization. Proper personal protective equipment and ventilation are essential when working with isocyanates. Regulations and guidelines exist for the safe use, storage, and disposal of isocyanate-containing materials to minimize health and environmental risks.

- Isocyanate-free alternatives and sustainable approaches: Research is ongoing to develop isocyanate-free alternatives and more sustainable approaches in polymer chemistry. This includes the exploration of bio-based isocyanates, non-isocyanate polyurethanes, and alternative chemistries that can provide similar properties without the associated health and environmental concerns of traditional isocyanates. These efforts aim to address regulatory pressures and market demands for safer and more environmentally friendly materials.

02 Applications of isocyanates in coatings and adhesives

Isocyanates play a significant role in the formulation of high-performance coatings and adhesives. They are used to create durable, chemical-resistant finishes and strong bonding agents. In coatings, isocyanates contribute to improved weatherability and scratch resistance. For adhesives, they enhance bonding strength and flexibility across various substrates.Expand Specific Solutions03 Isocyanate-based foam production

Isocyanates are crucial components in the production of polyurethane foams. These foams find applications in insulation, cushioning, and packaging. The reaction between isocyanates and polyols, along with blowing agents, creates the cellular structure of the foam. Control of this reaction allows for the production of foams with varying densities and properties.Expand Specific Solutions04 Safety and handling of isocyanates

Due to their high reactivity, isocyanates require careful handling and safety measures. Exposure can cause respiratory irritation and sensitization. Proper personal protective equipment, ventilation, and storage are essential. Developments in safer handling techniques and less hazardous alternatives are ongoing areas of research in the industry.Expand Specific Solutions05 Environmental and sustainable aspects of isocyanates

Research is ongoing to develop more environmentally friendly isocyanate-based products and processes. This includes the use of bio-based raw materials, reducing volatile organic compound (VOC) emissions, and improving the recyclability of isocyanate-containing materials. Efforts are also being made to find alternatives to traditional isocyanates that maintain similar performance characteristics while reducing environmental impact.Expand Specific Solutions

Key Industry Players

The isocyanate applications in automotive manufacturing market is in a mature growth stage, with a substantial global market size estimated in the billions of dollars. The technology has reached a high level of maturity, with established players like BASF, Covestro, and Dow dominating the landscape. These companies have extensive R&D capabilities and product portfolios. Emerging players such as Wanhua Chemical are also making significant strides, particularly in the Asia-Pacific region. The market is characterized by ongoing innovation in eco-friendly and high-performance isocyanate formulations, driven by stringent environmental regulations and the automotive industry's demand for lightweight, durable materials.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced isocyanate-based solutions for automotive manufacturing, focusing on polyurethane systems. Their technology includes high-performance MDI (methylene diphenyl diisocyanate) products specifically designed for automotive applications. These MDI-based systems offer improved durability, weather resistance, and thermal insulation properties for vehicle components[1]. Wanhua has also introduced low-VOC (volatile organic compound) isocyanate formulations, addressing environmental concerns in automotive production[2]. Their innovative approach includes the development of bio-based isocyanates, derived from renewable resources, which can reduce the carbon footprint of automotive parts while maintaining high performance standards[3].

Strengths: Comprehensive product range, focus on sustainability, strong R&D capabilities. Weaknesses: Potential regulatory challenges due to isocyanate toxicity concerns, dependency on petrochemical feedstocks for non-bio-based products.

Dow Global Technologies LLC

Technical Solution: Dow has pioneered several isocyanate applications in automotive manufacturing, with a focus on polyurethane systems. Their VORASTAR™ technology platform offers a range of fast-curing, high-performance polyurethane solutions for automotive interiors and exteriors[4]. Dow's isocyanate-based products include advanced foam systems for seating, which provide enhanced comfort and durability while reducing weight[5]. They have also developed isocyanate-terminated prepolymers that offer improved adhesion and flexibility for automotive sealants and adhesives. Dow's research has led to the creation of low-emission isocyanate formulations, addressing environmental and health concerns in automotive production processes[6].

Strengths: Extensive global presence, diverse product portfolio, strong focus on sustainability. Weaknesses: High research and development costs, potential exposure to raw material price fluctuations.

Core Isocyanate Patents

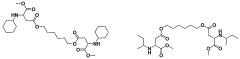

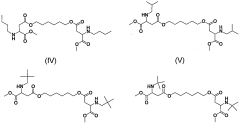

Durable coating compositions containing novel aspartic amine compounds

PatentWO2006066031A1

Innovation

- A novel coating composition utilizing amine and hydroxy amine functional compounds that react with isocyanates to form low VOC coatings with an optimal balance of pot life and curing time, providing excellent adhesion, stone chip resistance, and UV resistance, suitable for both clear and primer finishes.

Durable coating compositions containing aspartic amine compounds

PatentActiveUS7608303B2

Innovation

- A coating composition comprising a polyisocyanate crosslinking agent and an isocyanate-reactive component, specifically amine functional compounds with cycloaliphatic norbornane derivatives, which form a binder that provides a balance of pot life and curing time, offering excellent adhesion, weatherability, and resistance to UV degradation.

Environmental Impact

The environmental impact of isocyanate applications in automotive manufacturing is a critical consideration for the industry. Isocyanates, primarily used in the production of polyurethane foams and coatings, have both positive and negative effects on the environment throughout their lifecycle.

On the positive side, isocyanate-based materials contribute to vehicle weight reduction, leading to improved fuel efficiency and reduced emissions during the use phase of automobiles. Polyurethane foams, for instance, provide excellent insulation properties, enhancing energy efficiency in climate control systems. Additionally, the durability of isocyanate-based coatings extends the lifespan of automotive components, potentially reducing the need for frequent replacements and associated resource consumption.

However, the production and disposal of isocyanate-containing materials pose significant environmental challenges. The manufacturing process of isocyanates involves the use of toxic chemicals and energy-intensive reactions, contributing to air and water pollution. Emissions of volatile organic compounds (VOCs) during production and application can lead to the formation of ground-level ozone, a major component of smog.

The disposal of isocyanate-containing automotive parts at the end of their life cycle presents another environmental concern. While some polyurethane materials can be recycled, the process is often complex and energy-intensive. Incineration of these materials can release harmful substances, including nitrogen oxides and hydrogen cyanide, necessitating advanced emission control systems.

Efforts to mitigate the environmental impact of isocyanates in automotive manufacturing are ongoing. Many manufacturers are exploring bio-based alternatives and developing more environmentally friendly production processes. Advanced recycling technologies are being researched to improve the end-of-life management of isocyanate-based materials.

Regulatory bodies worldwide are implementing stricter controls on isocyanate use and disposal. This has led to increased investment in containment systems, worker protection, and emission reduction technologies in automotive manufacturing facilities. The industry is also focusing on developing water-based and solvent-free formulations to reduce VOC emissions during application processes.

In conclusion, while isocyanates offer significant benefits in automotive manufacturing, their environmental impact remains a complex issue. The industry's challenge lies in balancing the performance advantages of these materials with the need for sustainable production and disposal practices. Ongoing research and technological advancements are crucial in addressing these environmental concerns and moving towards more sustainable automotive manufacturing processes.

On the positive side, isocyanate-based materials contribute to vehicle weight reduction, leading to improved fuel efficiency and reduced emissions during the use phase of automobiles. Polyurethane foams, for instance, provide excellent insulation properties, enhancing energy efficiency in climate control systems. Additionally, the durability of isocyanate-based coatings extends the lifespan of automotive components, potentially reducing the need for frequent replacements and associated resource consumption.

However, the production and disposal of isocyanate-containing materials pose significant environmental challenges. The manufacturing process of isocyanates involves the use of toxic chemicals and energy-intensive reactions, contributing to air and water pollution. Emissions of volatile organic compounds (VOCs) during production and application can lead to the formation of ground-level ozone, a major component of smog.

The disposal of isocyanate-containing automotive parts at the end of their life cycle presents another environmental concern. While some polyurethane materials can be recycled, the process is often complex and energy-intensive. Incineration of these materials can release harmful substances, including nitrogen oxides and hydrogen cyanide, necessitating advanced emission control systems.

Efforts to mitigate the environmental impact of isocyanates in automotive manufacturing are ongoing. Many manufacturers are exploring bio-based alternatives and developing more environmentally friendly production processes. Advanced recycling technologies are being researched to improve the end-of-life management of isocyanate-based materials.

Regulatory bodies worldwide are implementing stricter controls on isocyanate use and disposal. This has led to increased investment in containment systems, worker protection, and emission reduction technologies in automotive manufacturing facilities. The industry is also focusing on developing water-based and solvent-free formulations to reduce VOC emissions during application processes.

In conclusion, while isocyanates offer significant benefits in automotive manufacturing, their environmental impact remains a complex issue. The industry's challenge lies in balancing the performance advantages of these materials with the need for sustainable production and disposal practices. Ongoing research and technological advancements are crucial in addressing these environmental concerns and moving towards more sustainable automotive manufacturing processes.

Safety Regulations

Safety regulations play a crucial role in the application of isocyanates in automotive manufacturing. These regulations are designed to protect workers, consumers, and the environment from the potential hazards associated with isocyanate exposure. The Occupational Safety and Health Administration (OSHA) in the United States has established specific guidelines for the use of isocyanates in industrial settings, including the automotive industry.

One of the primary safety regulations focuses on personal protective equipment (PPE). Workers handling isocyanates are required to wear appropriate respiratory protection, such as air-purifying respirators or supplied-air respirators, depending on the concentration of isocyanates in the air. Additionally, impervious gloves, protective clothing, and eye protection are mandatory to prevent skin and eye contact with isocyanates.

Ventilation requirements are another critical aspect of safety regulations. Automotive manufacturing facilities must implement adequate ventilation systems to maintain isocyanate concentrations below permissible exposure limits (PELs). This often involves the use of local exhaust ventilation systems and regular air monitoring to ensure compliance with OSHA standards.

Training and education are essential components of isocyanate safety regulations. Employers are required to provide comprehensive training to workers on the hazards of isocyanates, proper handling procedures, and emergency response protocols. This training must be conducted regularly and updated as new information becomes available.

Storage and handling regulations are also in place to minimize the risk of accidental releases or spills. Isocyanates must be stored in tightly sealed containers in well-ventilated areas, away from sources of heat or ignition. Specific guidelines for transportation and disposal of isocyanate-containing materials are outlined by regulatory agencies to prevent environmental contamination.

Emergency response planning is a critical component of safety regulations. Facilities using isocyanates must have detailed emergency procedures in place, including spill containment protocols, evacuation plans, and first-aid measures for potential exposure incidents.

Monitoring and record-keeping requirements are enforced to ensure ongoing compliance with safety regulations. Employers must maintain accurate records of employee exposure levels, medical examinations, and incident reports related to isocyanate use.

As environmental concerns grow, regulations are evolving to address the broader impact of isocyanate use. This includes stricter controls on volatile organic compound (VOC) emissions and the development of more environmentally friendly alternatives to traditional isocyanate-based products in automotive manufacturing.

One of the primary safety regulations focuses on personal protective equipment (PPE). Workers handling isocyanates are required to wear appropriate respiratory protection, such as air-purifying respirators or supplied-air respirators, depending on the concentration of isocyanates in the air. Additionally, impervious gloves, protective clothing, and eye protection are mandatory to prevent skin and eye contact with isocyanates.

Ventilation requirements are another critical aspect of safety regulations. Automotive manufacturing facilities must implement adequate ventilation systems to maintain isocyanate concentrations below permissible exposure limits (PELs). This often involves the use of local exhaust ventilation systems and regular air monitoring to ensure compliance with OSHA standards.

Training and education are essential components of isocyanate safety regulations. Employers are required to provide comprehensive training to workers on the hazards of isocyanates, proper handling procedures, and emergency response protocols. This training must be conducted regularly and updated as new information becomes available.

Storage and handling regulations are also in place to minimize the risk of accidental releases or spills. Isocyanates must be stored in tightly sealed containers in well-ventilated areas, away from sources of heat or ignition. Specific guidelines for transportation and disposal of isocyanate-containing materials are outlined by regulatory agencies to prevent environmental contamination.

Emergency response planning is a critical component of safety regulations. Facilities using isocyanates must have detailed emergency procedures in place, including spill containment protocols, evacuation plans, and first-aid measures for potential exposure incidents.

Monitoring and record-keeping requirements are enforced to ensure ongoing compliance with safety regulations. Employers must maintain accurate records of employee exposure levels, medical examinations, and incident reports related to isocyanate use.

As environmental concerns grow, regulations are evolving to address the broader impact of isocyanate use. This includes stricter controls on volatile organic compound (VOC) emissions and the development of more environmentally friendly alternatives to traditional isocyanate-based products in automotive manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!