Future Trends in Isocyanate Manufacturing Processes

Isocyanate Evolution and Objectives

Isocyanates have played a pivotal role in the polymer industry since their discovery in the early 20th century. The evolution of isocyanate manufacturing processes has been driven by the increasing demand for polyurethanes and other isocyanate-based products across various sectors, including automotive, construction, and electronics.

The journey of isocyanate production began with the pioneering work of Otto Bayer in 1937, who developed the first commercial process for producing toluene diisocyanate (TDI). This breakthrough laid the foundation for the rapid growth of the polyurethane industry. As the demand for isocyanates surged, manufacturers focused on improving production efficiency and developing new isocyanate variants to meet diverse application requirements.

In the 1960s and 1970s, the introduction of methylene diphenyl diisocyanate (MDI) marked a significant milestone in isocyanate technology. MDI offered superior properties compared to TDI, leading to its widespread adoption in rigid foam applications. This period also saw the development of more sophisticated production techniques, such as continuous flow processes and improved catalysts, which enhanced yield and reduced environmental impact.

The 1980s and 1990s witnessed a shift towards greener manufacturing processes, driven by increasing environmental concerns and stricter regulations. Manufacturers began exploring alternative raw materials and developing cleaner production methods to minimize the use of hazardous substances and reduce emissions.

In recent years, the focus has shifted towards sustainable and bio-based isocyanates. Research efforts are being directed at developing isocyanates from renewable resources, such as plant-based oils and biomass. This aligns with the growing global emphasis on sustainability and circular economy principles.

Looking ahead, the objectives for future isocyanate manufacturing processes are multifaceted. Firstly, there is a strong drive towards improving energy efficiency and reducing the carbon footprint of production facilities. This includes the integration of renewable energy sources and the development of more efficient catalysts and reaction systems.

Secondly, there is a growing emphasis on enhancing product safety and reducing the potential health risks associated with isocyanate handling. This involves the development of low-emission formulations and safer alternatives to traditional isocyanates, particularly for spray applications.

Thirdly, the industry is focusing on increasing the versatility of isocyanates to meet emerging market demands. This includes the development of novel isocyanate chemistries that offer improved performance characteristics, such as enhanced durability, fire resistance, and thermal insulation properties.

Lastly, there is a concerted effort to integrate advanced technologies, such as artificial intelligence and machine learning, into isocyanate manufacturing processes. These technologies promise to optimize production parameters, predict and prevent equipment failures, and enable more precise quality control.

Market Demand Analysis for Isocyanates

The global isocyanate market has been experiencing steady growth, driven by increasing demand from various end-use industries such as automotive, construction, furniture, and electronics. The market size for isocyanates was valued at approximately $25 billion in 2020 and is projected to reach $40 billion by 2027, with a compound annual growth rate (CAGR) of around 6% during the forecast period.

The automotive industry remains a key driver for isocyanate demand, particularly in the production of polyurethane foams for vehicle interiors, seats, and insulation. As the automotive sector continues to evolve with a focus on lightweight materials and improved fuel efficiency, the demand for isocyanate-based products is expected to rise further.

In the construction sector, isocyanates are widely used in the production of rigid polyurethane foams for insulation purposes. With growing emphasis on energy-efficient buildings and stringent building codes, the demand for high-performance insulation materials is increasing, thereby boosting the isocyanate market.

The furniture industry is another significant consumer of isocyanates, particularly in the production of flexible polyurethane foams for cushioning and upholstery. As the global furniture market expands, driven by urbanization and changing lifestyles, the demand for isocyanates in this sector is expected to grow steadily.

Emerging applications in the electronics industry, such as the use of isocyanates in the production of protective coatings and adhesives for electronic components, are also contributing to market growth. The rapid expansion of the electronics sector, particularly in developing economies, is likely to create new opportunities for isocyanate manufacturers.

Geographically, Asia-Pacific is the largest and fastest-growing market for isocyanates, accounting for over 40% of global consumption. This growth is primarily attributed to the region's booming construction and automotive industries, particularly in China and India. North America and Europe follow as significant markets, driven by ongoing technological advancements and increasing adoption of eco-friendly polyurethane products.

However, the isocyanate market faces challenges related to environmental and health concerns associated with certain types of isocyanates. This has led to increased regulatory scrutiny and a push towards the development of more sustainable and less toxic alternatives. As a result, manufacturers are investing in research and development to create bio-based isocyanates and improve production processes to minimize environmental impact.

Current Challenges in Isocyanate Production

The isocyanate manufacturing industry faces several significant challenges that impact production efficiency, environmental sustainability, and product quality. One of the primary concerns is the high energy consumption associated with traditional production methods. The synthesis of isocyanates typically requires elevated temperatures and pressures, leading to substantial energy costs and carbon emissions. This energy-intensive process not only affects the environmental footprint but also impacts the overall production economics.

Another critical challenge is the use of hazardous raw materials, particularly phosgene, in conventional isocyanate production. Phosgene is highly toxic and poses significant safety risks to workers and surrounding communities. The handling, storage, and transportation of phosgene require stringent safety measures, increasing operational complexity and costs. Moreover, regulatory pressures to phase out phosgene usage are intensifying, necessitating the development of alternative production routes.

The generation of by-products and waste streams presents a further challenge in isocyanate manufacturing. Current processes often result in the formation of unwanted side products, which can reduce yield and require additional purification steps. The disposal of these by-products and waste materials poses environmental concerns and adds to production costs. Improving reaction selectivity and developing more efficient separation techniques are crucial areas for addressing this challenge.

Product quality and consistency are ongoing concerns in isocyanate production. Variations in raw material quality, process conditions, and equipment performance can lead to inconsistencies in the final product. Maintaining strict quality control throughout the manufacturing process is essential to meet the demanding specifications of end-users, particularly in industries such as automotive and construction where isocyanates are critical components.

The volatility of raw material prices, especially for key feedstocks like benzene and toluene, presents a significant economic challenge for isocyanate manufacturers. Fluctuations in these prices can have a substantial impact on production costs and profit margins. Developing strategies to mitigate raw material price risks and improve supply chain resilience is crucial for maintaining competitiveness in the market.

Lastly, the industry faces increasing pressure to adopt more sustainable and environmentally friendly production methods. This includes reducing greenhouse gas emissions, minimizing water usage, and developing bio-based alternatives to petroleum-derived isocyanates. Meeting these sustainability goals while maintaining product performance and economic viability remains a significant challenge for manufacturers.

Current Isocyanate Synthesis Methods

01 Phosgenation of amines

One of the primary methods for manufacturing isocyanates involves the phosgenation of amines. This process typically uses phosgene to react with primary amines, resulting in the formation of isocyanates. The reaction is often carried out in multiple stages and may involve the use of catalysts or specific reaction conditions to improve yield and selectivity.- Phosgenation of amines: One of the primary methods for manufacturing isocyanates involves the phosgenation of amines. This process typically uses phosgene to react with primary amines, resulting in the formation of isocyanates. The reaction is often carried out in multiple stages and may require specific catalysts or reaction conditions to optimize yield and purity.

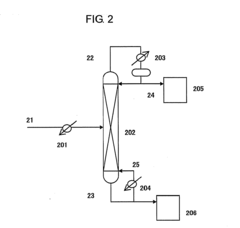

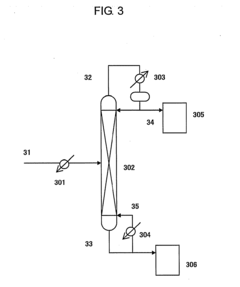

- Thermal decomposition of carbamates: Another method for producing isocyanates is through the thermal decomposition of carbamates. This process involves heating carbamates at high temperatures, causing them to break down into isocyanates and alcohols. The reaction conditions, including temperature and pressure, are carefully controlled to maximize the yield of isocyanates while minimizing side reactions.

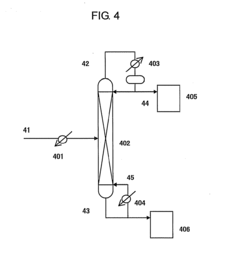

- Catalytic processes for isocyanate synthesis: Various catalytic processes have been developed for the synthesis of isocyanates. These methods often involve the use of specific catalysts to promote the formation of isocyanates from different precursors. Catalysts may include metal complexes, organometallic compounds, or other specialized materials that enhance reaction rates and selectivity.

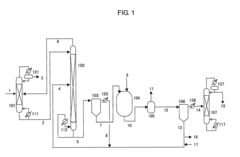

- Continuous flow processes for isocyanate production: Continuous flow processes have been developed for the large-scale production of isocyanates. These methods involve the continuous feeding of reactants through a series of reaction chambers or tubes, allowing for better control of reaction conditions and improved efficiency. Continuous processes can offer advantages in terms of safety, product quality, and production capacity compared to batch processes.

- Green chemistry approaches to isocyanate synthesis: Recent research has focused on developing more environmentally friendly methods for isocyanate production. These green chemistry approaches aim to reduce the use of toxic reagents, minimize waste generation, and improve overall sustainability. Examples include the use of alternative reagents, solvent-free reactions, and the development of bio-based precursors for isocyanate synthesis.

02 Non-phosgene routes

Alternative methods for isocyanate production that do not involve phosgene have been developed to address safety and environmental concerns. These processes may use different starting materials or reaction pathways, such as the reaction of carbamates with dehydrating agents or the use of carbon monoxide and nitro compounds. These methods aim to provide more sustainable and less hazardous manufacturing processes for isocyanates.Expand Specific Solutions03 Continuous manufacturing processes

Continuous manufacturing processes for isocyanates have been developed to improve efficiency and reduce costs. These processes often involve specialized reactor designs, precise control of reaction conditions, and continuous feed of reactants and removal of products. Continuous processes can offer advantages in terms of product quality, safety, and scalability compared to batch processes.Expand Specific Solutions04 Catalytic processes

Various catalytic processes have been developed to enhance the production of isocyanates. These may involve the use of homogeneous or heterogeneous catalysts to improve reaction rates, selectivity, or yield. Catalysts can also help in reducing energy requirements or enabling milder reaction conditions. The choice of catalyst often depends on the specific isocyanate being produced and the desired process characteristics.Expand Specific Solutions05 Purification and separation techniques

The manufacturing of isocyanates often requires sophisticated purification and separation techniques to obtain high-quality products. These may include distillation, crystallization, extraction, or membrane separation processes. Advanced purification methods are crucial for removing byproducts, unreacted starting materials, and other impurities that can affect the quality and performance of the final isocyanate product.Expand Specific Solutions

Key Players in Isocyanate Industry

The isocyanate manufacturing industry is in a mature stage, with a global market size estimated to exceed $20 billion by 2025. The technology landscape is characterized by incremental innovations focused on process efficiency and sustainability. Key players like BASF, Covestro, and Wanhua Chemical dominate the market with established production capabilities. Emerging trends include bio-based isocyanates and improved catalysts for enhanced selectivity. Companies are investing in R&D to develop greener manufacturing processes and meet stringent environmental regulations. The competitive landscape is intensifying with Asian manufacturers expanding capacity, while Western companies focus on specialty products and technological differentiation.

BASF Corp.

Wanhua Chemical Group Co., Ltd.

Innovative Isocyanate Technologies

- A continuous flow process involving the mixing of acyl hydrazides with nitrous acid to form acyl azides, followed by heating in the presence of an organic solvent to produce isocyanates through Curtius rearrangement, offering a safer and more scalable method for isocyanate synthesis.

- A process involving the reaction of diaryl carbonates with amine compounds to form aryl carbamates, followed by transferring the reaction mixture to a thermal decomposition vessel where the aryl carbamates undergo thermal decomposition to produce isocyanates, with specific conditions and solvents used to enhance yield and purity, including the use of aromatic hydroxy compounds as solvents and acid cleaning to remove high-boiling point by-products.

Environmental Impact of Isocyanate Production

The environmental impact of isocyanate production has become a critical concern in the chemical industry, particularly as global demand for polyurethanes continues to rise. Traditional manufacturing processes for isocyanates, especially toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI), have been associated with significant environmental challenges.

One of the primary environmental concerns is the emission of volatile organic compounds (VOCs) during production. These emissions contribute to air pollution and can have adverse effects on both human health and ecosystems. Additionally, the use of phosgene as a key raw material in conventional isocyanate synthesis poses serious safety and environmental risks due to its toxicity and potential for accidental release.

Water pollution is another significant issue associated with isocyanate manufacturing. The production process generates wastewater containing various contaminants, including unreacted raw materials, byproducts, and catalysts. If not properly treated, these effluents can harm aquatic ecosystems and potentially contaminate groundwater sources.

Energy consumption in isocyanate production is substantial, contributing to greenhouse gas emissions and climate change. The high temperatures and pressures required for synthesis reactions, as well as the energy-intensive purification processes, result in a considerable carbon footprint for the industry.

To address these environmental challenges, manufacturers are increasingly focusing on developing more sustainable production methods. One promising approach is the implementation of gas-phase phosgenation technology, which reduces solvent usage and minimizes waste generation. This technique has shown potential for significantly reducing environmental impact compared to traditional liquid-phase processes.

Another area of innovation is the exploration of phosgene-free routes for isocyanate synthesis. These alternative pathways aim to eliminate the use of highly toxic phosgene, thereby improving process safety and reducing environmental risks. While still in various stages of development, such methods could revolutionize the industry's environmental profile in the coming years.

Advancements in catalysis are also playing a crucial role in enhancing the environmental performance of isocyanate production. Novel catalysts are being developed to improve reaction selectivity, reduce energy requirements, and minimize the formation of unwanted byproducts. These innovations not only contribute to cleaner production processes but also improve overall resource efficiency.

As regulatory pressures increase and consumer demand for sustainable products grows, the isocyanate industry is likely to see accelerated adoption of green chemistry principles. This shift will involve optimizing reaction conditions, implementing closed-loop systems for solvent recovery, and exploring bio-based raw materials as alternatives to petroleum-derived feedstocks.

Safety Regulations in Isocyanate Manufacturing

Safety regulations in isocyanate manufacturing have become increasingly stringent in recent years, reflecting the growing awareness of the potential hazards associated with these chemicals. Regulatory bodies worldwide, including the Occupational Safety and Health Administration (OSHA) in the United States and the European Chemicals Agency (ECHA), have implemented comprehensive guidelines to ensure worker safety and environmental protection.

One of the key areas of focus in safety regulations is exposure control. Manufacturers are required to implement robust engineering controls, such as closed systems and local exhaust ventilation, to minimize worker exposure to isocyanates. Personal protective equipment (PPE) requirements have also been enhanced, with specific emphasis on respiratory protection and impermeable protective clothing.

Environmental regulations have become more stringent, with stricter limits on emissions and waste disposal. Manufacturers are now required to implement advanced air pollution control systems and wastewater treatment facilities to minimize the release of isocyanates and their byproducts into the environment.

Risk assessment and management have gained prominence in regulatory frameworks. Companies are mandated to conduct thorough risk assessments of their manufacturing processes and implement comprehensive risk management strategies. This includes regular monitoring of workplace air quality, medical surveillance of workers, and emergency response planning.

Training and education requirements have been expanded to ensure that all personnel involved in isocyanate manufacturing are well-informed about the associated risks and proper handling procedures. Regular refresher courses and competency assessments are now standard practice in the industry.

Storage and transportation regulations have also been tightened. Specific requirements for storage facilities, including temperature control and spill containment measures, have been implemented. Transportation of isocyanates is subject to strict guidelines, including proper labeling, packaging, and documentation requirements.

Incident reporting and investigation procedures have been standardized across the industry. Manufacturers are required to report all incidents involving isocyanates, no matter how minor, and conduct thorough investigations to prevent recurrence.

Looking ahead, future trends in safety regulations for isocyanate manufacturing are likely to focus on further reducing exposure limits, implementing more advanced monitoring technologies, and enhancing emergency response capabilities. There is also a growing emphasis on sustainability, with regulations expected to promote the development of greener manufacturing processes and the use of alternative, less hazardous raw materials where possible.