Universal cementing plug

a plug and plug technology, applied in the field of cementing plugs, can solve the problems of affecting increasing the cost of manufacturing, and normal pressure rise at the surface, so as to increase the wiping efficiency of the wipers on the plugs, increase the wiping efficiency, and increase the surface contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

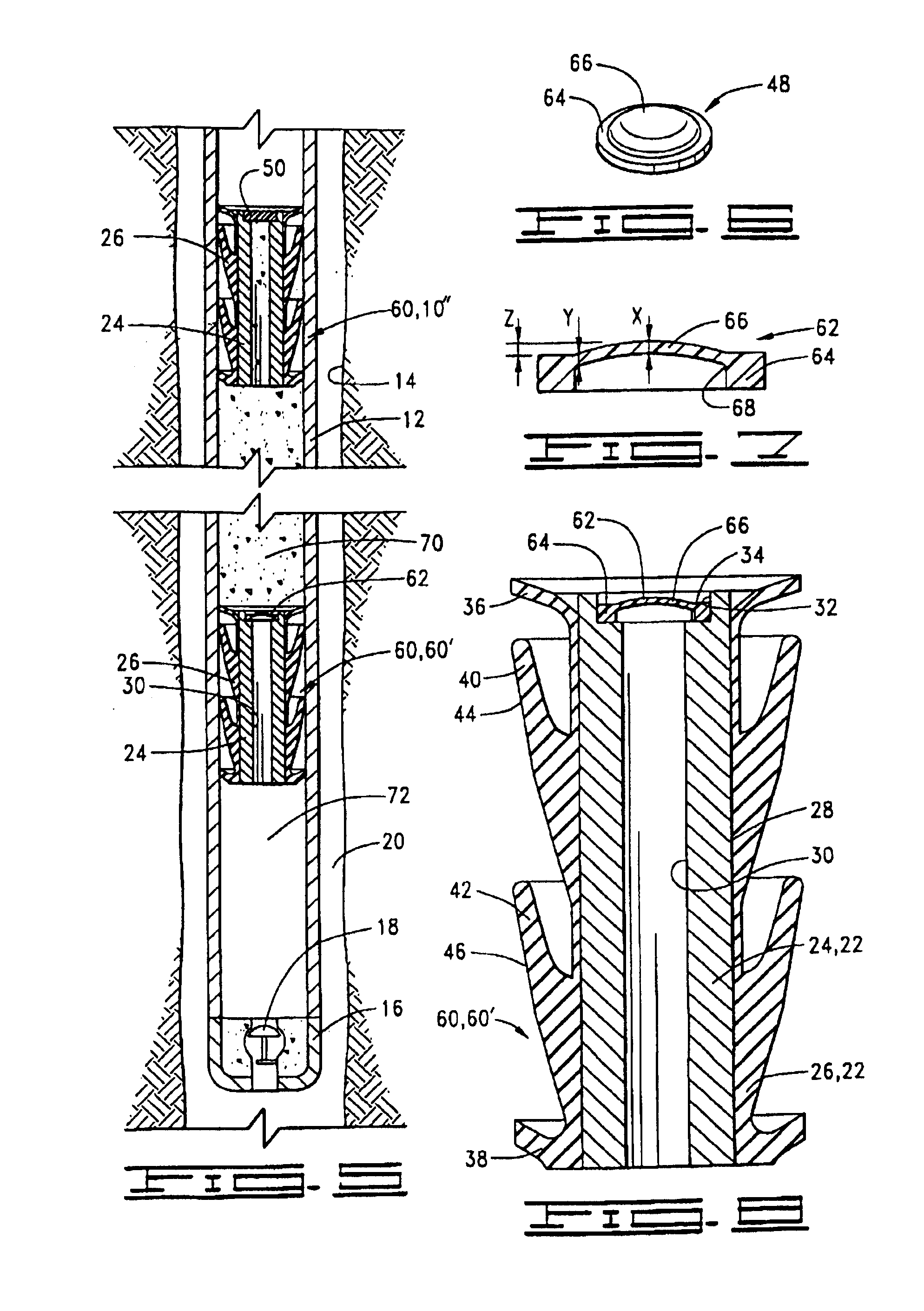

[0044]Although various materials may be used for shearable insert 62, a preferred material is 23570 glass-filled plastic from Baelow-Hunt, Inc., of Tulsa, Okla. This material has a working temperature range of room temperature to about 410° F.

[0045]The following table illustrates the pressure at which domed portion 66 shears based on different values of X and Y using this material.

[0046]

XYShear Pressure0.100°0.125°370psi0.125°0.150°700psi0.131°-0.135°0.175°1200psi

[0047]In a preferred embodiment, but not by way of limitation, the height Z of domed portion 66 above ring portion 64 is approximately equal to center thickness X of domed portion 66.

[0048]Second embodiment shearable material 62 may be positioned on shoulder 34 in body member 24 of plug subassembly 22 to form second embodiment bottom plug 60′, as seen in FIGS. 5 and 8.

[0049]In second embodiment cementing plug 60, top plug 10″ used with bottom plug 60′ is identical to that in first embodiment cementing plug 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com