Fuel hose and method of its production

a technology of fuel hoses and hoses, which is applied in the direction of pipes, plasma techniques, synthetic resin layered products, etc., can solve the problems of low bonding affinity of ordinary fluororesin with other structural materials, risk of partial delamination of tubular fluororesin inner ply from outer ply, and inability to firmly bond two plies using an adhesive alone. , to achieve the effect of reducing the cost of the fuel hose, prolonging the servi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 6

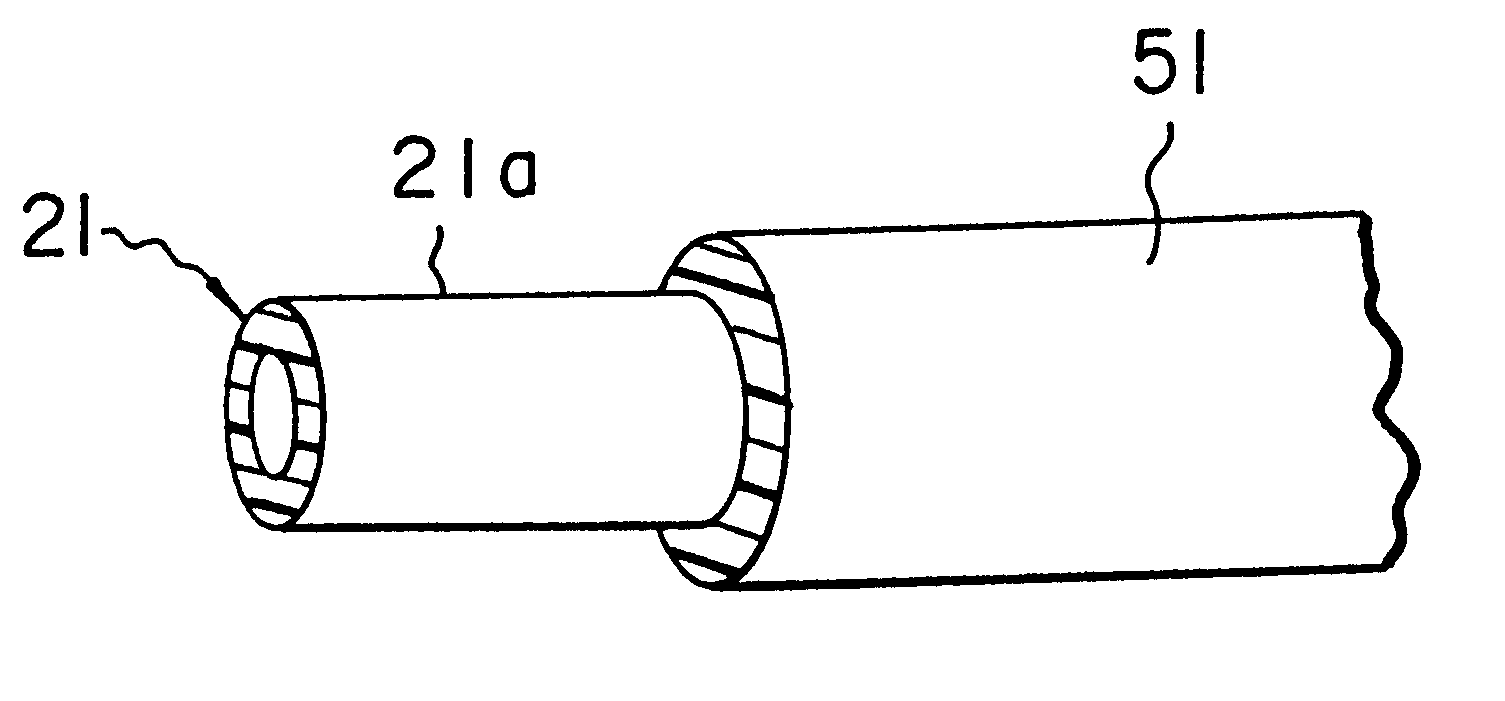

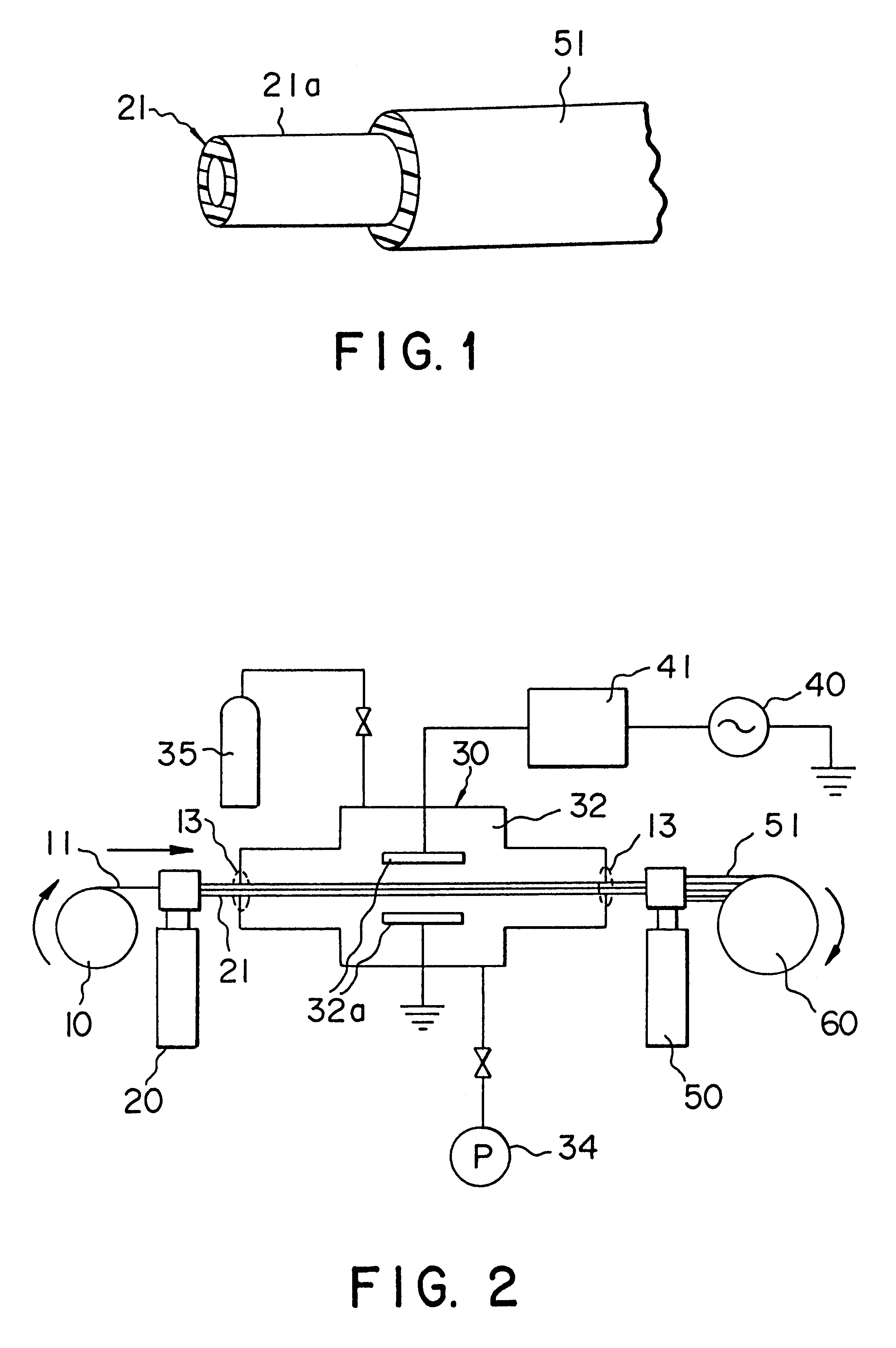

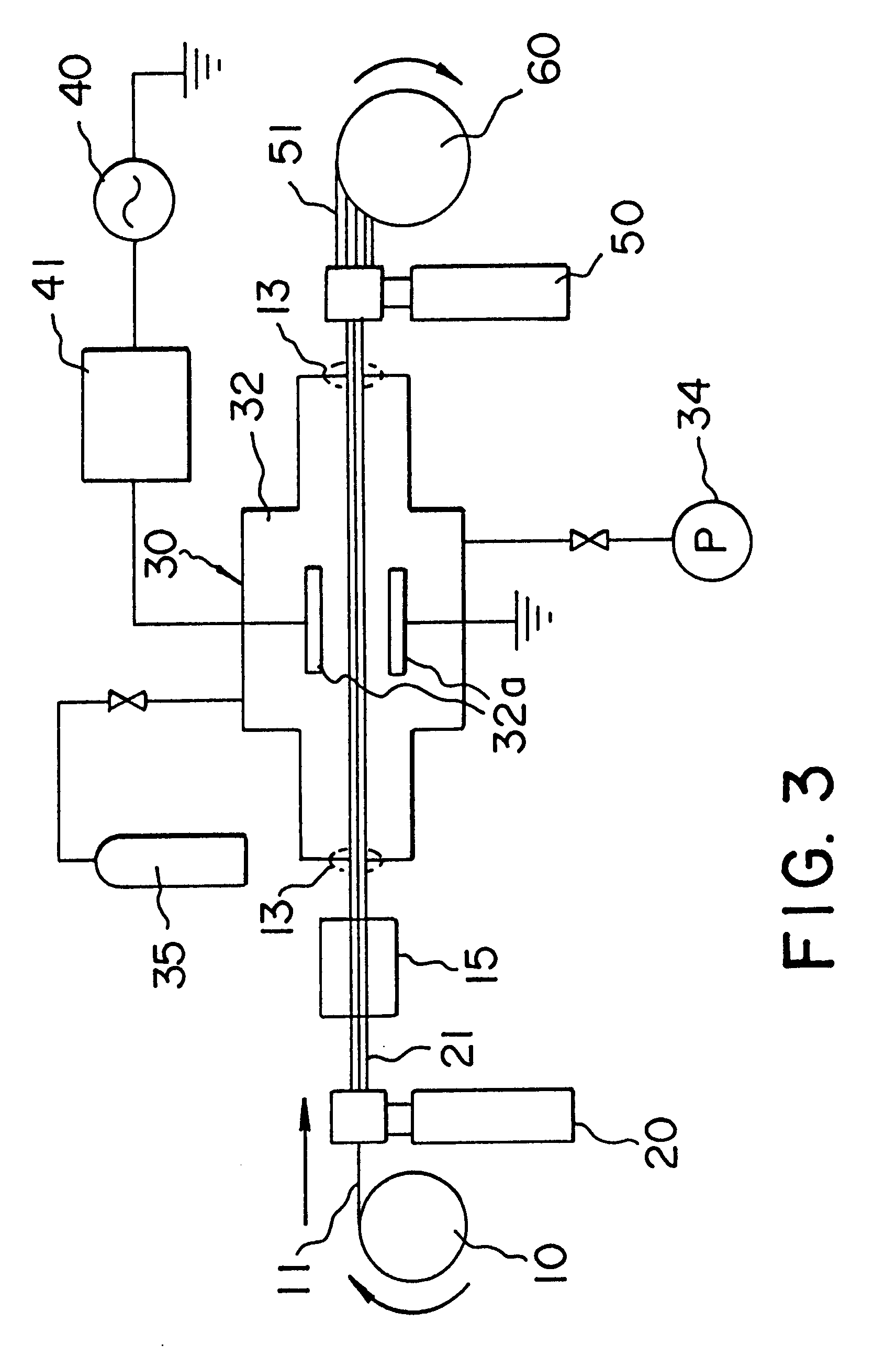

Using a vacuum plasma apparatus illustrated in FIG. 2 for plasma treatment, ETFE for the tubular fluororesin inner ply and ECO for the outer ply to be formed on the peripheral surface of said inner ply, a fuel hose was fabricated. In this production process, Ar gas was used as the electrical discharge gas, the degree of vacuum was set at 0.05 Torr, and the thickness of the ECO ply was controlled at 2 mm. After extrusion of the outer ply from the extruder 50, the laminate was taken up on the mandrel takeup 60 and the ECO ply 51 was then vulcanized at 160.degree. C. for 45 minutes. Otherwise the procedure of Examples 1-5 was repeated to provide a fuel hose of Example 6.

examples 7 and 8

Except that CTFE was used as the molding material for the tubular fluororesin inner ply and the electrical discharge gases and degrees of vacuum shown below in Table 2 were employed, fuel hoses were fabricated in otherwise the same manner as Examples 1-5.

TABLE 2 Electrical Degree of vacuum Example discharge gas (Torr) 7 N.sub.2 0.1 8 N.sub.2 0.05

examples 9-14

Except that FEP was used as the molding material for the tubular fluororesin inner ply and the electrical discharge gases and degrees of vacuum shown below in Table 3 were employed, fuel hoses were fabricated in otherwise the same manner as Examples 1-5.

TABLE 3 Electrical Degree of vacuum Example discharge gas (Torr) 9 Ar 0.1 10 Ar 0.05 11 N.sub.2 0.3 12 N.sub.2 0.1 13 N.sub.2 0.05 14 Ar + N.sub.2 0.05 15 Ar 0.05

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume resistivity | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com