Pulsed ion beam source

a technology of ion beams and ion beams, which is applied in the direction of ion beam tubes, electric discharge lamps, instruments, etc., can solve the problems of inability to commercialize, add complexity, size and expense to the system employing such map ion sources, and no commercial implementation has resulted, etc., to achieve efficient localization of gas puffs, reduce the rotation of ion beams, and reduce the effect of ion beam rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

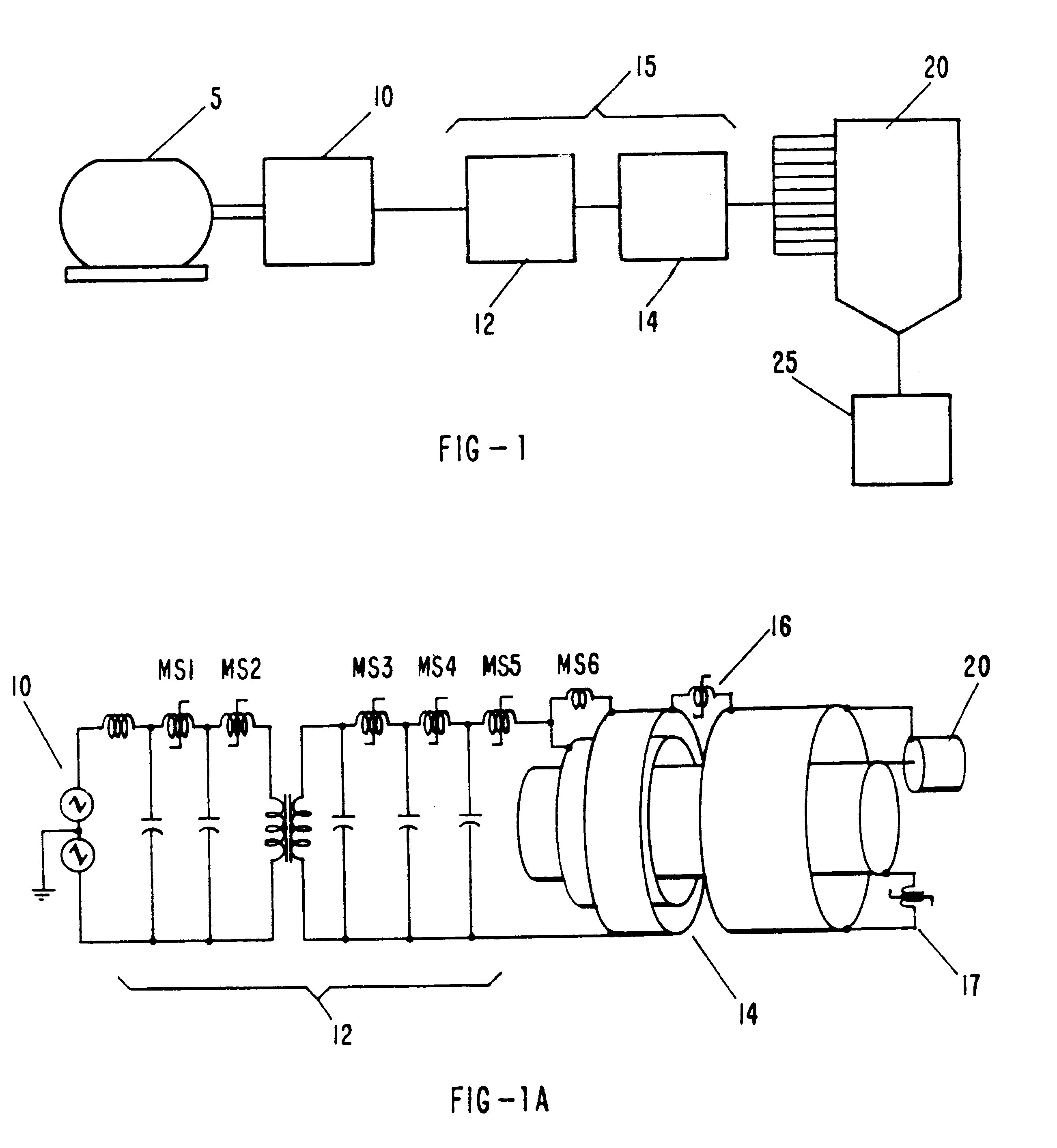

The following discussion is a description of one system which can be utilized to produce the ion beams for surface treatment of various materials. This system has two major subsystems, the pulsed power source and the MAP ion diode.

The MAP ion diode which forms the present invention, when combined with the RHEPP source, provides for an ion beam generator system capable of high average power and repetitive operation over an extended number of operating cycles for treating large surface areas of materials at commercially attractive costs. In particular, the ion beam generator of the present invention can produce high average power (1 kW-4 MW) pulsed ion beams at 0.1-2.5 MeV energies and pulse durations or lengths of from about 10 nanoseconds (ns)-2 microseconds (.mu.s) or longer as necessary for the particular application. The ion beam generator can directly deposit energy in the top 50 micrometers (.mu.m) of the surface of a material. The depth of treatment can be controlled by varyin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rise time | aaaaa | aaaaa |

| rise time | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com