MEMS sensor

a technology of inertial measurement and sensor, which is applied in the direction of microstructural devices, microstructure systems, coatings, etc., can solve the problems of increasing the cost and complexity of the semiconductor device manufacturing process, the current monolithic harpss fabrication process requires significantly complex and difficult process steps, and the widespread use of industries, so as to reduce the size of the device, reduce the amount of release etching, and the effect of sensitivity to the desired motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present disclosure will be more completely understood through the following description, which should be read in conjunction with the drawings. The skilled artisan will readily appreciate that the methods, apparatus and systems described herein are merely exemplary and that variations can be made without departing from the spirit and scope of the disclosure.

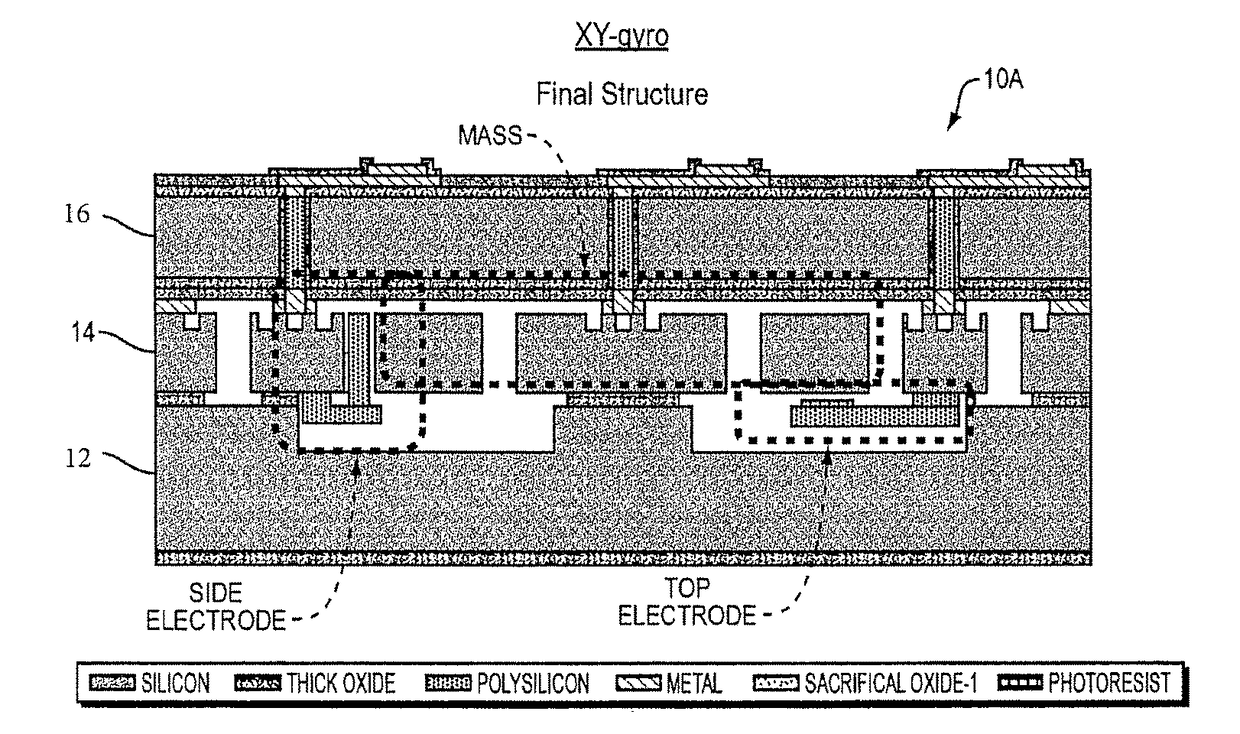

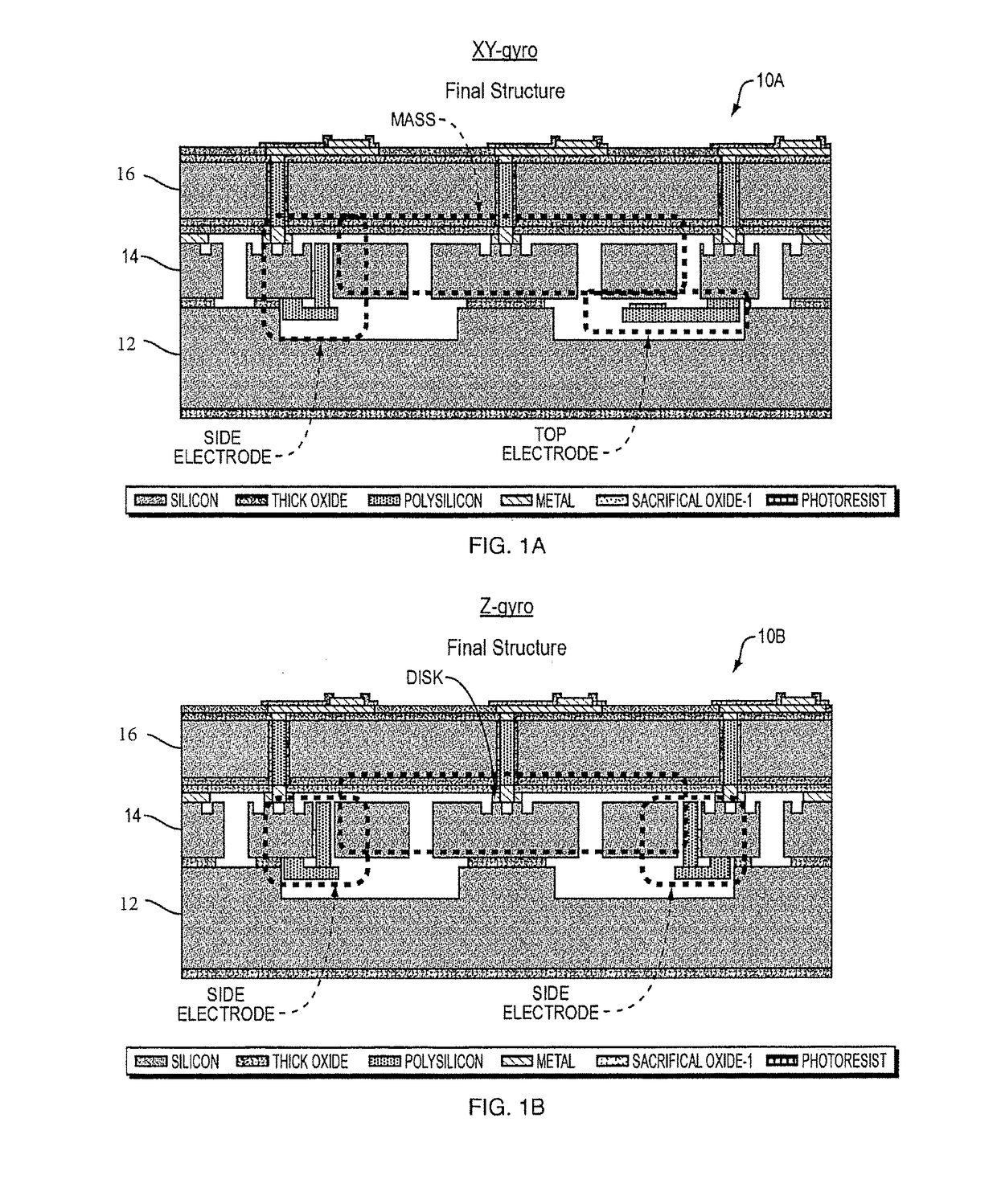

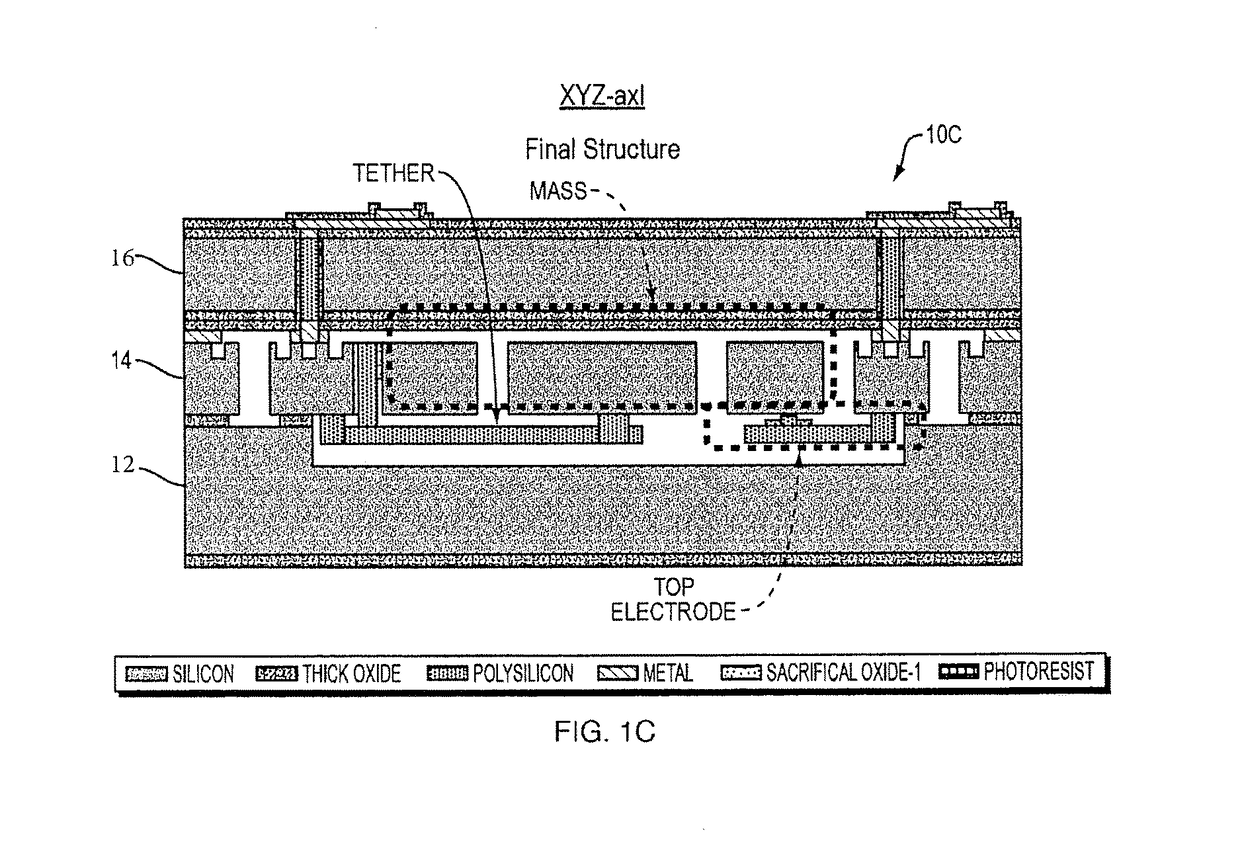

[0036]Technologies disclosed herein are directed towards sensing rotation and acceleration around all three axes of free space using an inertial measurement MEMS device. Such devices may have six degrees of freedom in their mechanical design to be able to sense six independent motion signals, i.e. linear acceleration along and angular velocity signals around three orthogonal axes of free space. The manufacturing techniques and designs disclosed herein may be used with any number of commercially available MEMS gyroscopes including those disclosed in the previously mentioned U.S. Pat. No. 7,023,065 United States Patent Ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com