Partition fluid separation

a technology of ceramic monoliths and fluids, applied in separation processes, liquid degasification, membranes, etc., can solve the problems of reduced power output of internal combustion engines, limited availability of high ron fuel, and generally more expensive fuel purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Synthesis of DENO-D400 Pre-Polymer

[0091]An aliphatic epoxy-polyether amine crosslinked membrane polymer was made with near equivalent amounts, 47.0 g of 1,2,7,8-Diepoxy-n-octane, or DENO (Aldrich) and 63.0 g of 400 mw Polypropylene Glycol bis 2 aminopropyl ether, or D400 (Aldrich / Huntsman). These were combined with 12.0 g Benzyl alcohol catalyst and 331.2 g toluene in a 1000 ml reaction flask, equipped with condenser and stirrer (Eurostar PWR CV81) operated at 250 rpm, and reacted for 2 hours at 100° C. This mixture was allowed to cool to 60° C., while stirring and monitoring torque. The reaction was quenched by dilution with toluene to a final pre-polymer concentration of 25% when the torque increase corresponded to 54% conversion by nmr (torque reading=10). The final epoxy:NH ratio was 1.05. The product was refrigerated at 0° C. prior to use.

example 2

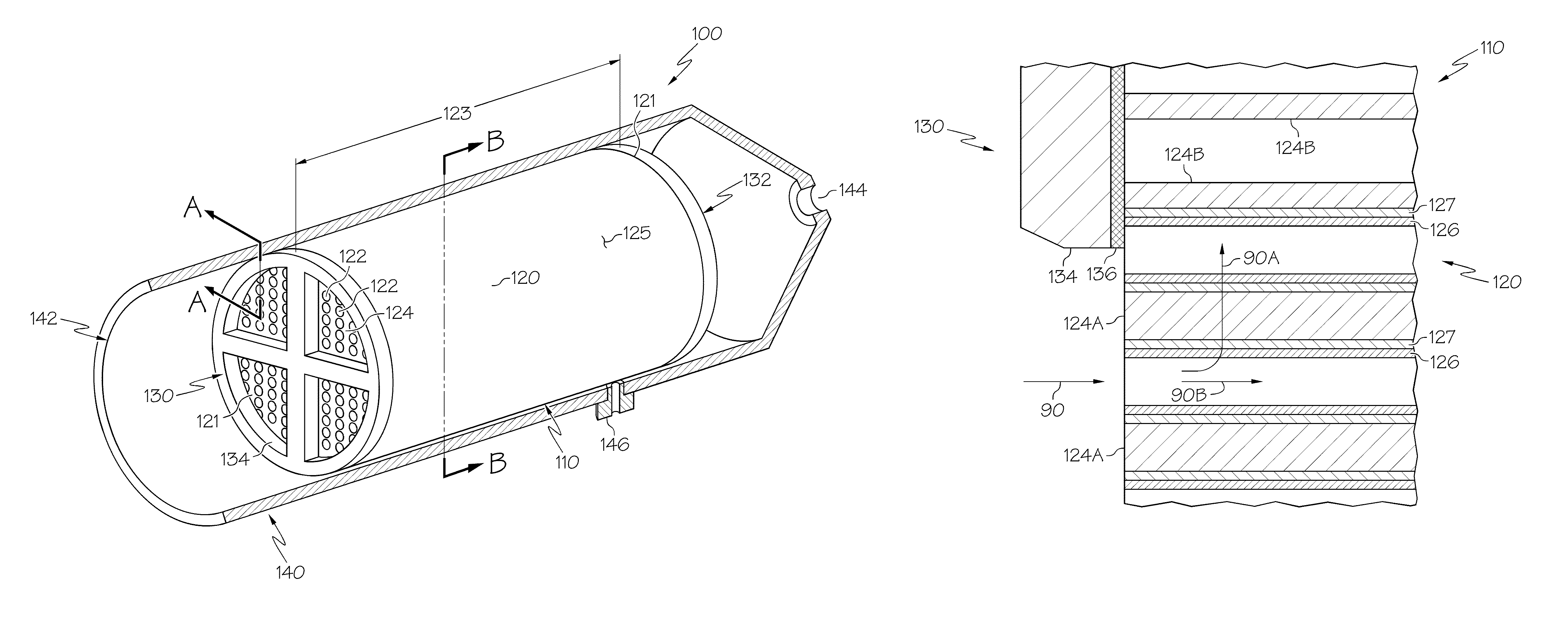

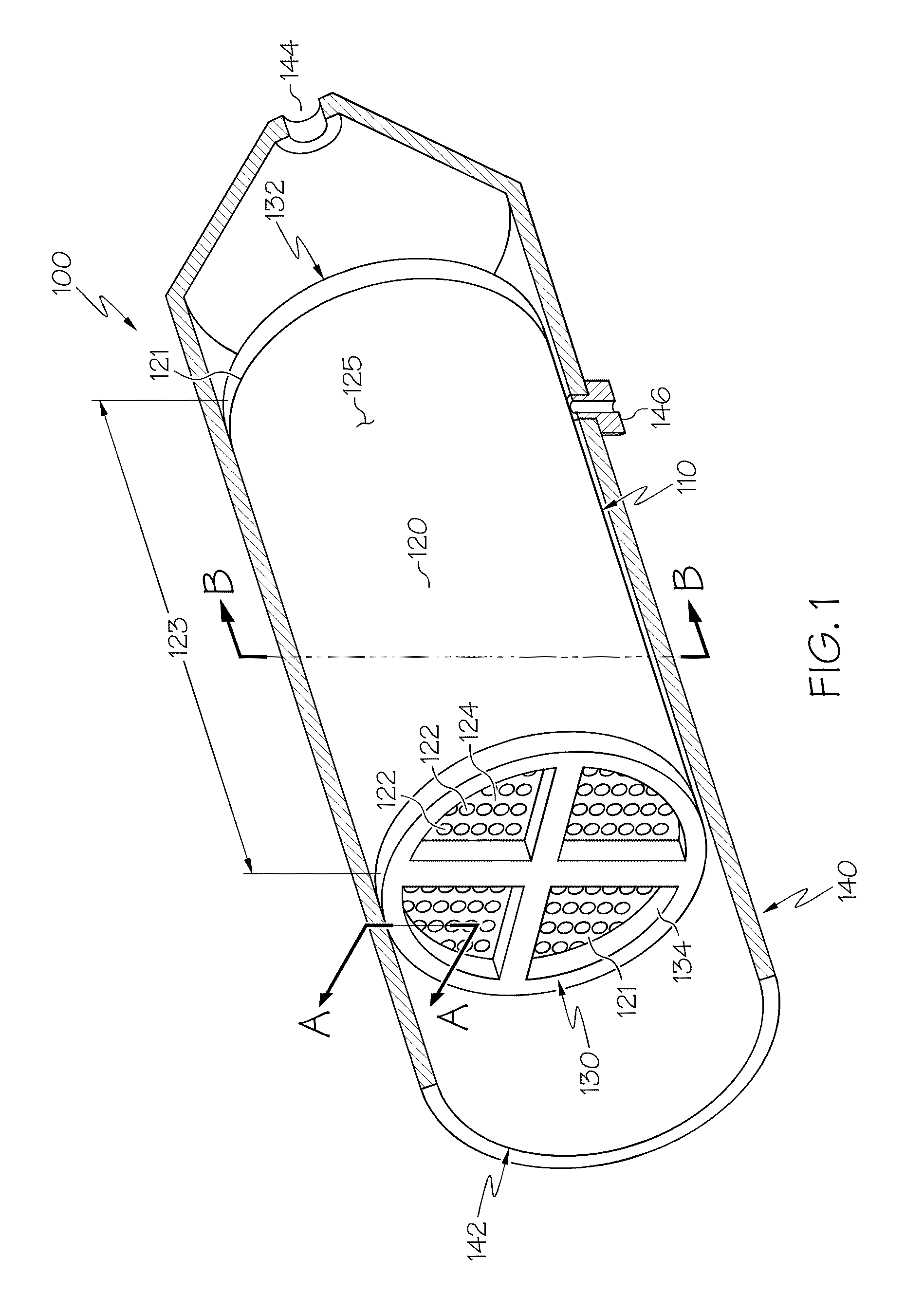

Coating of Partitioned Monolith

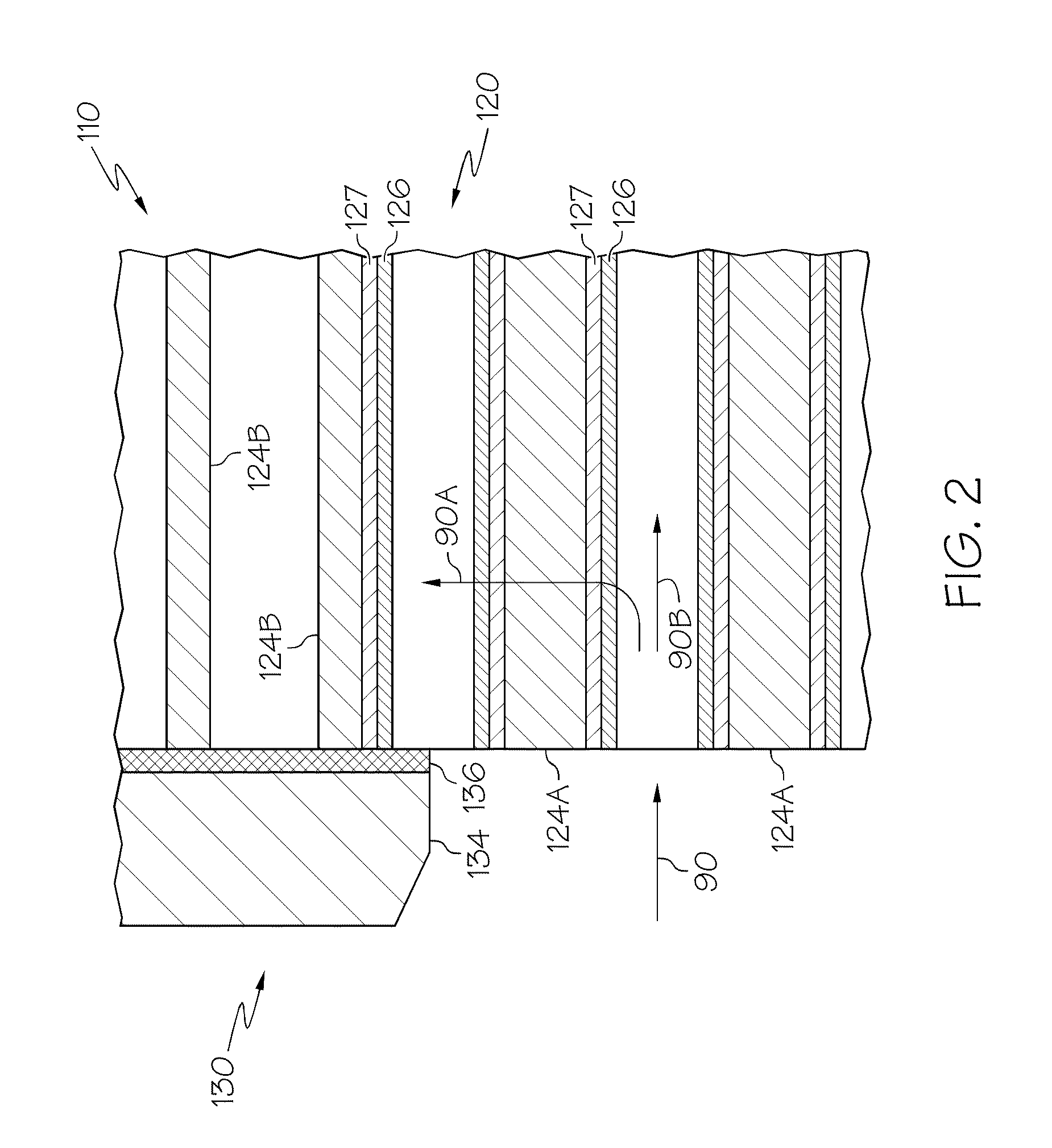

[0092]A nominally 2.4″ dia.×8″ long porous Mullite monolith, having nominally 1.8 mm channel diameter, was coated with a series of microparticulate metal oxide slurries and calcined as described in U.S. Pat. Pub No. 2008 / 0035557 to obtain a porous substrate having a titania surface of nominal 0.01 micron porosity. The monolith was partitioned into quadrant segments by fastening and sealing end rings with a ceramic filled epoxy cement. Each quadrant segment had 82 channels, with a surface area of 0.087 m2 and a total area of 0.348 m2. The partitioned ceramic monolith was designated 2L2R-33M.

[0093]The 0.01 micron porosity partitioned monolith was coated with a DENO-D400 polymer precursor prepared as described in Example 1 and coated in a manner similar to that described in Provisional US Pat Application based on 2011EM006 Example 4. Several coatings (7) were required to obtain a leak free polymer film. The first two coatings were preceded by wetting of t...

example 3

Gasoline Testing of Partitioned Monolith

[0097]The partitioned membrane monolith from Example 3 was evaluated for separation of gasoline into higher and lower octane fractions as described in U.S. Pat. No. 7,803,275 B2. The monolith was mounted vertically, with the inlet at the top of the housing and the retentate and permeate outlets at the low side. A regular grade 87 AKI (92.6 RON) US E10 gasoline was used as feed. Process conditions were established with a feed rate of 0.35 g / s at 400 kPag and about 155° C. inlet temperature. At these conditions about 80% of the gasoline feed is vaporized. The mixed phase feed was fed through a Bete WL½-90 spray nozzle (Bete Fog Nozzles, Inc, Greenfield, Mass.) to distribute the feed to the monolith channels of the segment selected. Unused sections were masked with a Viton face seal (160) at both ends of the monolith as described earlier and illustrated in FIGS. 6 and 7. The membrane module was insulated and operated adiabatically. A vacuum was m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com