Preparation method of porous-ceramic-supported graphene film

A graphene film and porous ceramic technology, applied in the field of graphene film preparation, can solve problems such as inability to use, and achieve the effects of low mass transfer resistance, simple and economical process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

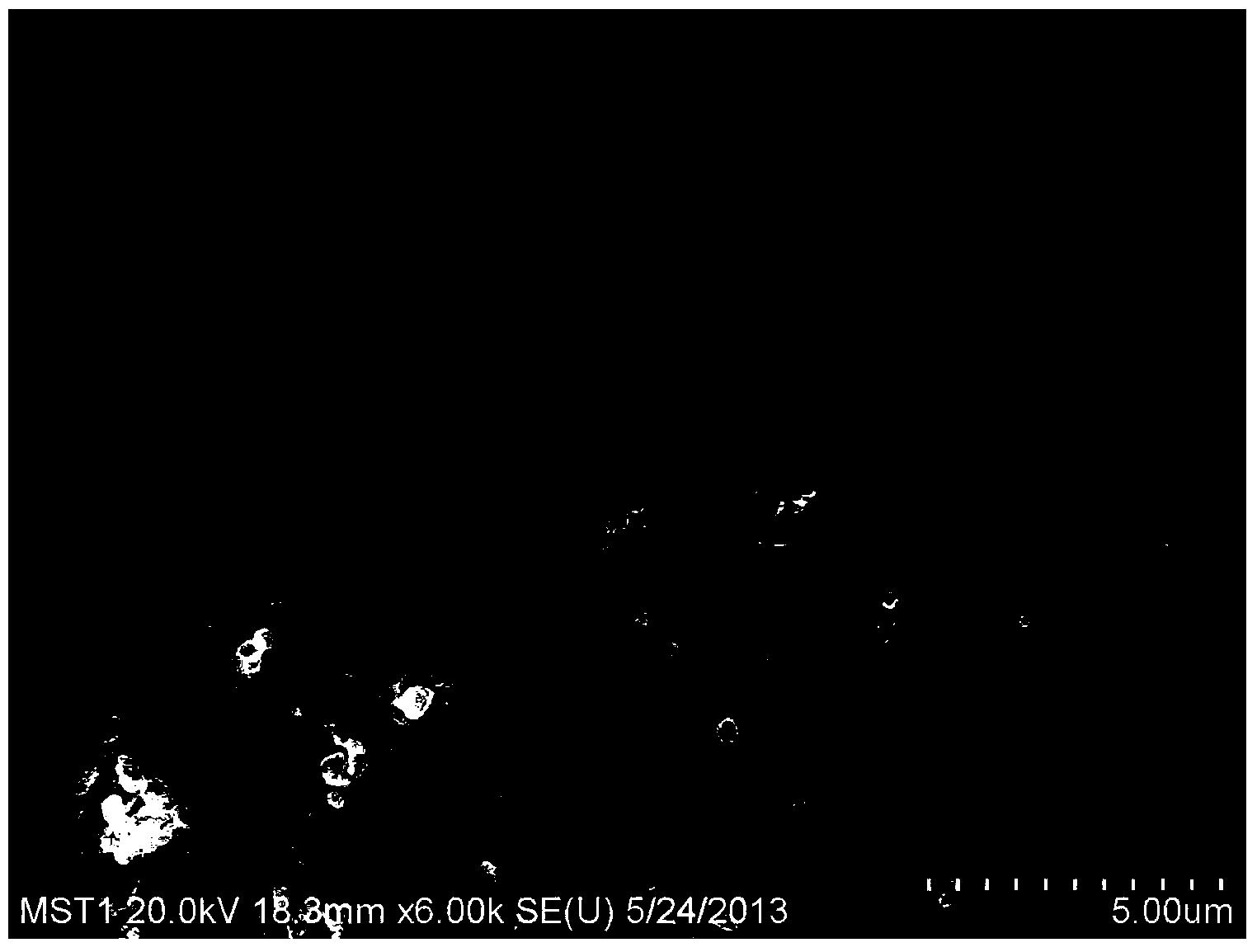

Image

Examples

Embodiment 1

[0020] 1) Mix γ-chloropropyltrimethoxysilane and toluene at a ratio of 3:40 to prepare a silane modification solution.

[0021] 2) The flake TiO with an average pore size of 50nm 2 The support body was placed in the modification solution and treated at 80°C for 2 hours. The support body was taken out from the modification solution, put into an oven, and treated at 110° C. for 4 hours.

[0022] 3) Weigh 0.15g of hydroxylated graphene, add 50mL of deionized water, stir for 5 hours, and then perform ultrasonication for 5 minutes until the hydroxylated graphene is completely dispersed in water;

[0023] 4) Coating the coating liquid on the outside of the inorganic ceramic support by the dip coating method, and the coating time is 40 seconds. After coating, the film was treated in an oven at a temperature of 70°C for 1 day.

[0024] 5) Repeat the film coating and drying process of 4) twice to obtain an organic-inorganic composite film of graphene material.

[0025] Measure the ...

Embodiment 2

[0027] 1) Mix γ-chloropropyltrimethoxysilane and absolute ethanol at a ratio of 2:40 to prepare a silane modification solution.

[0028] 2) The average pore size is 200nm tube type is Al 2 o 3 / ZrO 2 The support body was placed in the modification solution and treated at 90°C for 3 hours. The support body was taken out from the modification solution, put into an oven, and treated at 120° C. for 2 hours.

[0029] 3) Weigh 0.01g carboxylated graphene, add 50mL DMSO, stir for 8 hours, and then perform ultrasonication for 15 minutes until carboxylated graphene is completely dispersed in DMSO;

[0030] 4) Coating the coating liquid on the outside of the inorganic ceramic support by the dip coating method, and the coating time is 60 seconds. After coating, the film was treated in an oven at a temperature of 60°C for 2 days. An organic-inorganic composite film of a graphene material is obtained.

[0031] Measure the pervaporation separation performance of the composite membrane...

Embodiment 3

[0033] 1) Mix γ-chloropropyltrimethoxysilane and xylene at a ratio of 2:40 to prepare a silane modification solution.

[0034] 2) Tubular Al with an average pore diameter of 400nm 2 o 3 / ZrO 2 The support body was placed in the modification solution and treated at 80°C for 4 hours. The support body was taken out from the modification solution, put into an oven, and treated at 110° C. for 3 hours.

[0035] 3) Weigh 0.15g of mercaptographene, add 50mL of deionized water, stir for 7 hours, and then perform ultrasonication for 5 minutes until the mercaptographene is completely dispersed in deionized water;

[0036] 4) Coating the coating liquid on the outside of the inorganic ceramic support by the dip coating method, and the coating time is 50 seconds. After coating, the film was treated in an oven at a temperature of 70°C for 1 day.

[0037] 5) Repeat the coating and drying process of 4) three times to obtain an organic-inorganic composite film of graphene material. Measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com