Method for producing thioester group-containing organosilicon compound, thioester group-containing organosilicon compound, compounding agent for rubber, rubber composition, and tire

a technology of organosilicon and thioester group, which is applied in the direction of organic chemistry, transportation and packaging, and rolling resistance optimization, can solve the problems of low workability, high cost, and inability to achieve the desired low fuel consumption of the rubber composition of the tire, so as to achieve the desired low fuel consumption, reduce scorching, and improve the effect of reactivity and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

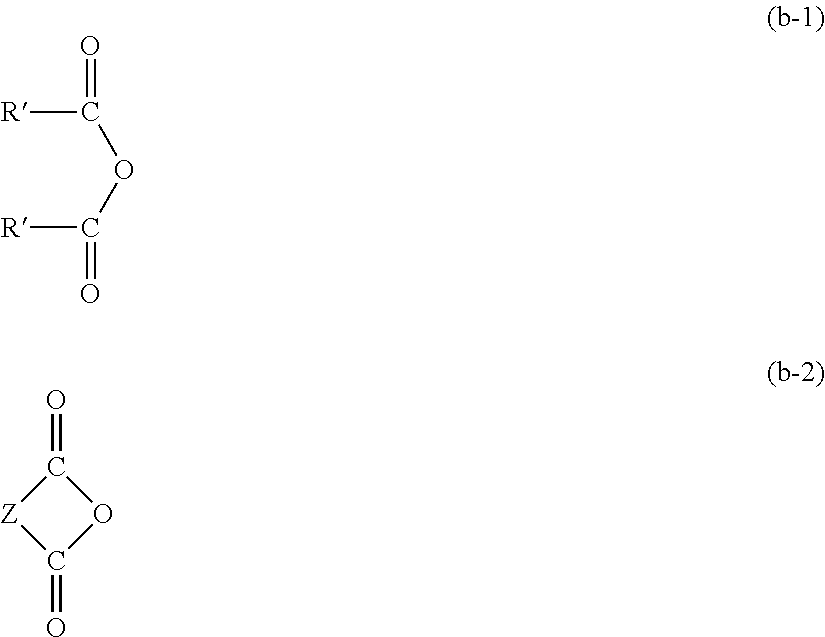

[0090]A 1 L separable flask equipped with an agitator, a reflux condenser, a dropping funnel, and a thermometer was charged with 102.1 g (1.0 mol) of acetic anhydride, 1.0 g (0.01 mol) of N,N-dimethylaminopyridine, and 300 g of toluene, and the mixture was heated to 70° C. in an oil bath. To this mixture, 243.2 g (1.0 mol) of γ-mercaptopropyltriethoxysilane (KBE-803 manufactured by Shin-Etsu Chemical Co., Ltd.) was added dropwise, and then, the mixture was stirred for 2 hours by heating to 70° C. Reaction was completed after confirming the complete disappearance of the peak from the mercaptosilane of the starting material and appearance of the peak from the thioesterified moiety by GC. The reaction solution was distilled at reduced pressure to remove toluene and obtain a colorless transparent liquid (yield, 310.7 g). The thus obtained reaction product had a viscosity of 2.7 mm2 / s, a specific weight of 1.026, and a refractive index of 1.477. 1H NMR spectrum revealed that the reaction...

example 2

[0092]A 1 L separable flask equipped with an agitator, a reflux condenser, a dropping funnel, and a thermometer was charged with 270.4 g (1.0 mol) of octanoic anhydride, 1.0 g (0.01 mol) of N,N-dimethylaminopyridine, and 300 g of toluene, and the mixture was heated to 70° C. in an oil bath. To this mixture, 243.2 g (1.0 mol) of γ-mercaptopropyltriethoxysilane (KBE-803 manufactured by Shin-Etsu Chemical Co., Ltd.) was added dropwise, and then, the mixture was stirred for 2 hours by heating to 70° C. Reaction was completed after confirming the complete disappearance of the peak from the mercaptosilane of the starting material and appearance of the peak from the thioesterified moiety by GC. The reaction solution was distilled at reduced pressure to remove toluene and obtain a yellow transparent liquid (yield, 416.1 g). The thus obtained reaction product had a viscosity of 250.7 mm2 / s, a specific weight of 1.031, and a refractive index of 1.484. 1H NMR spectrum revealed that the reactio...

example 3

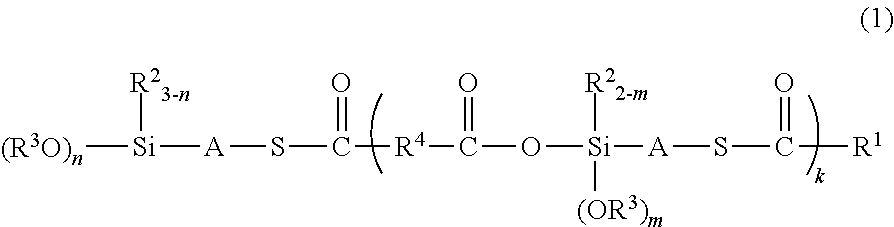

[0094]A 1 L separable flask equipped with an agitator, a reflux condenser, a dropping funnel, and a thermometer was charged with 100.1 g (1.0 mol) of succinic anhydride, 1.0 g (0.01 mol) of N,N-dimethylaminopyridine, and 300 g of toluene, and the mixture was heated to 70° C. in an oil bath. To this mixture, 243.2 g (1.0 mol) of γ-mercaptopropyltriethoxysilane (KBE-803 manufactured by Shin-Etsu Chemical Co., Ltd.) was added dropwise, and then, the mixture was stirred for 2 hours by heating to 70° C. Reaction was completed after confirming the complete disappearance of the peak from the mercaptosilane of the starting material by GC. The reaction solution was distilled at reduced pressure to remove toluene and obtain a colorless transparent liquid (yield, 326.2 g). The thus obtained reaction product had a viscosity of 232 mm2 / s, a specific weight of 1.029, and a refractive index of 1.483. 1H NMR spectrum revealed that the reaction product was a mixture of the compounds represented by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction temperature | aaaaa | aaaaa |

| reaction temperature | aaaaa | aaaaa |

| reaction temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com