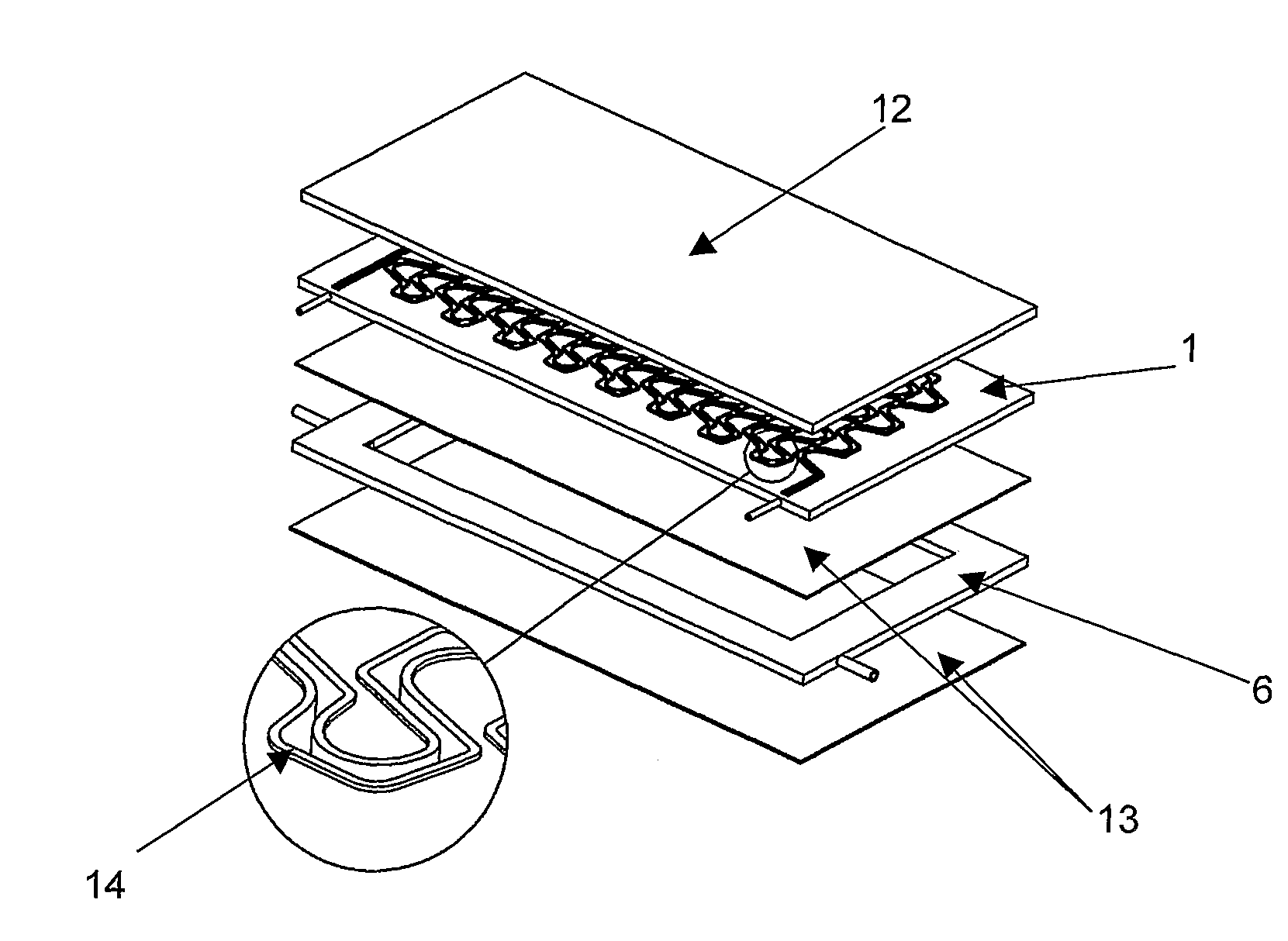

Multipurpose flow module

a flow module and multi-purpose technology, applied in the direction of liquid-gas reaction process, pipe heating/cooling, chemical/physical processes, etc., can solve the problems of more turbulence in the fluid flow, manufacturing limitations, and difficulty in creating the desired pressure condition, so as to prevent leakage and improve the effect of chemical resistance and good chemical resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

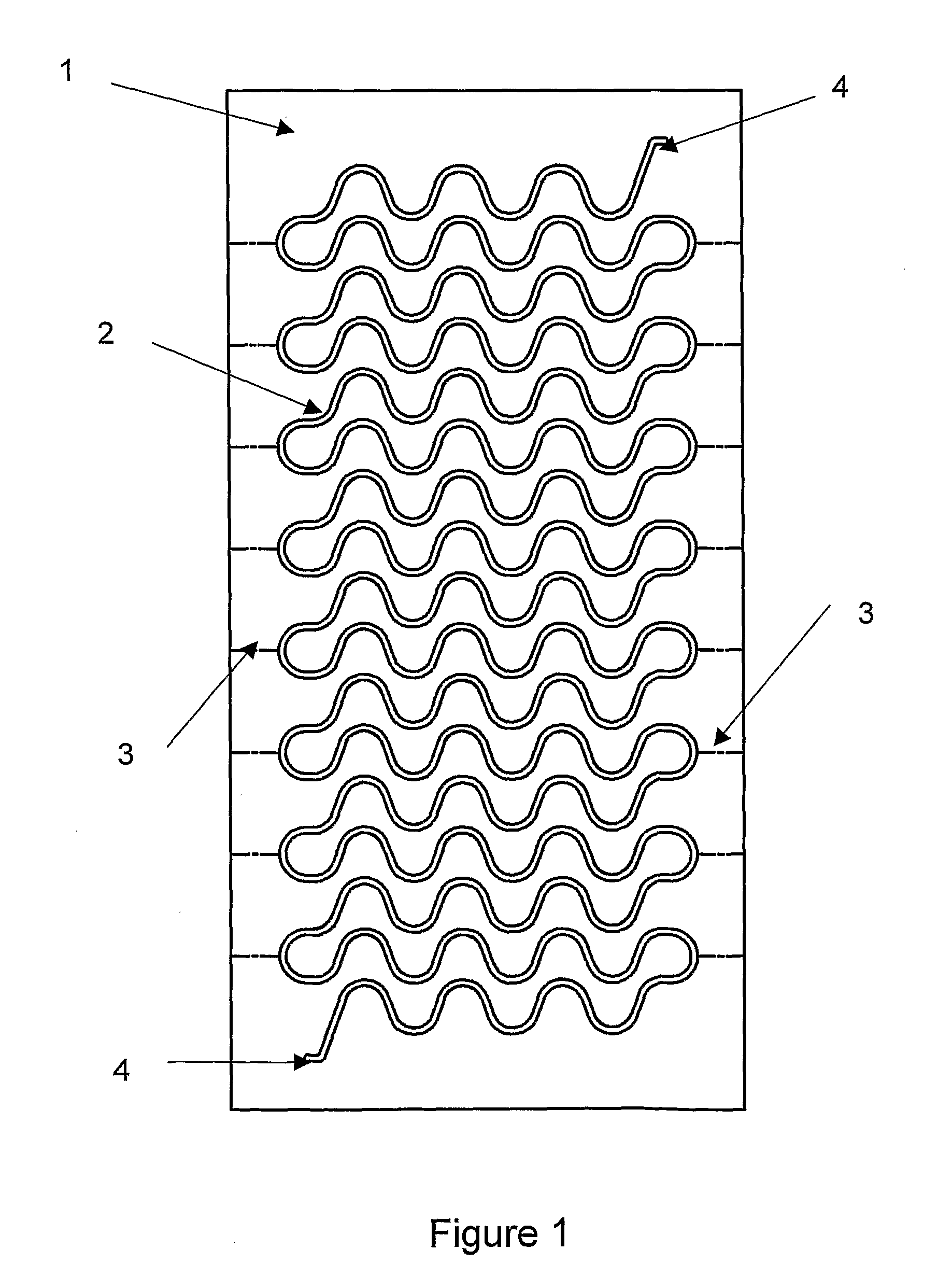

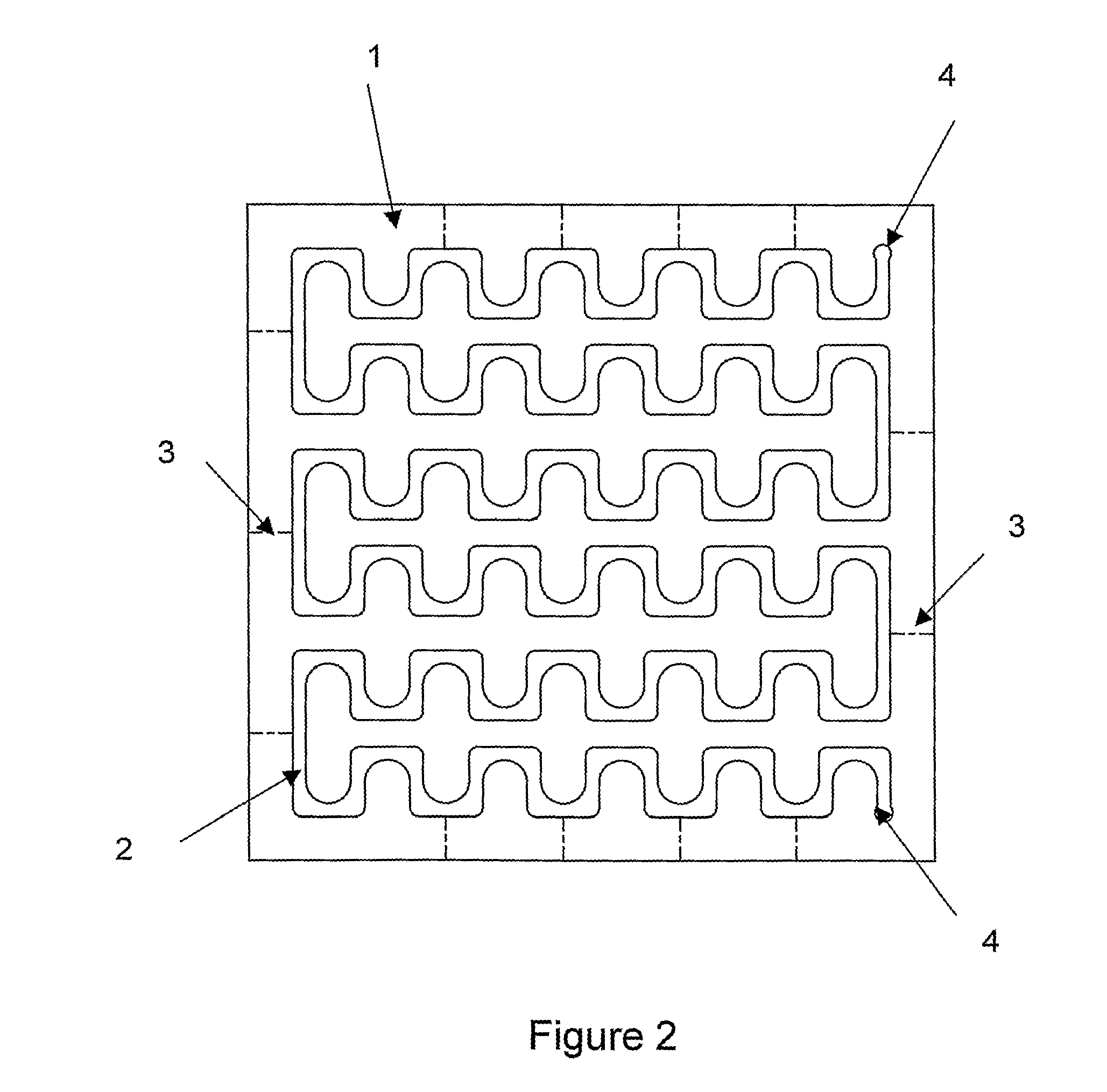

[0100]In Example 1 a multipurpose flow module was tested, which module operates at process flow rates of 1.5-10 l / hr (0.1-0.7 m / s). The flow rate in this example was 5 l / hr. The micro-mixing timescale in a water-like fluid, as determined by reactive mixing experiment, was 30 milliseconds. This corresponds to a pressure drop of 0.5 Bar per flow plate. The utility fluid was water having a temperature at about 10° C. and a flow rate of 40 l / hr was cooling a hotter process fluid, which had a flow rate of 5 l / hr—in the initial part of the module are cooling rates of more than 30° C. / s achieved for this pseudo co-current configuration.

[0101]The combination of good mixing and redistribution of fluid within the channel and the high heat transfer rates were combined to provide excellent thermal control of the reaction medium. The pressure was up to 20 bar—referring to a stainless steel reactor with GORE® ePTFE gasket and HPLC fittings.

[0102]The design of the multipurpose flow module also off...

example 2

[0103]A multipurpose flow module was tested in this example, the dimensions of the flow channel of the module were: cross-section 1.5 mm×2 mm in average, process hydraulic diameter 2.16 mm, length of the flow channel 3.113 m. The flow rates were within the range of 1-10 l / hr during the tests.

[0104]The shape of the residence time distributions were similar at all flow rates tested, which can be seen in FIG. 22, indicating common hydrodynamics across these conditions. FIG. 22 shows a smooth peak, with sharper rise and longer decrease. The width of the distribution decreases as the flow rate is increased. There are neither short cuts nor stagnant regions, thus a plug flow was created in the tested flow channel.

example 3

[0105]In Example 3 a disperser nozzle was tested in a multipurpose flow module. The nozzle flow was measured in continuous operating mode, for different sized nozzles, for a range of feed pump operating pressures.

[0106]The flow ranges are summarised in the graph of FIG. 23. The graph shows flow rates for different nozzle sizes with a fully open valve. By using an operating valve, i.e. pulsed mode, the flow rate could be lowered down to less than 1% of these flows for each nozzle size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com