Method and apparatus for producing bag with mouth member

a mouth member and bag technology, applied in the field of bag production can solve the problems of thinning the film or forming holes in the film, affecting the production efficiency of bags, etc., and achieves the effect of preventing liquid leakage from the bag with a mouth member, stable inhibition, and high drop strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

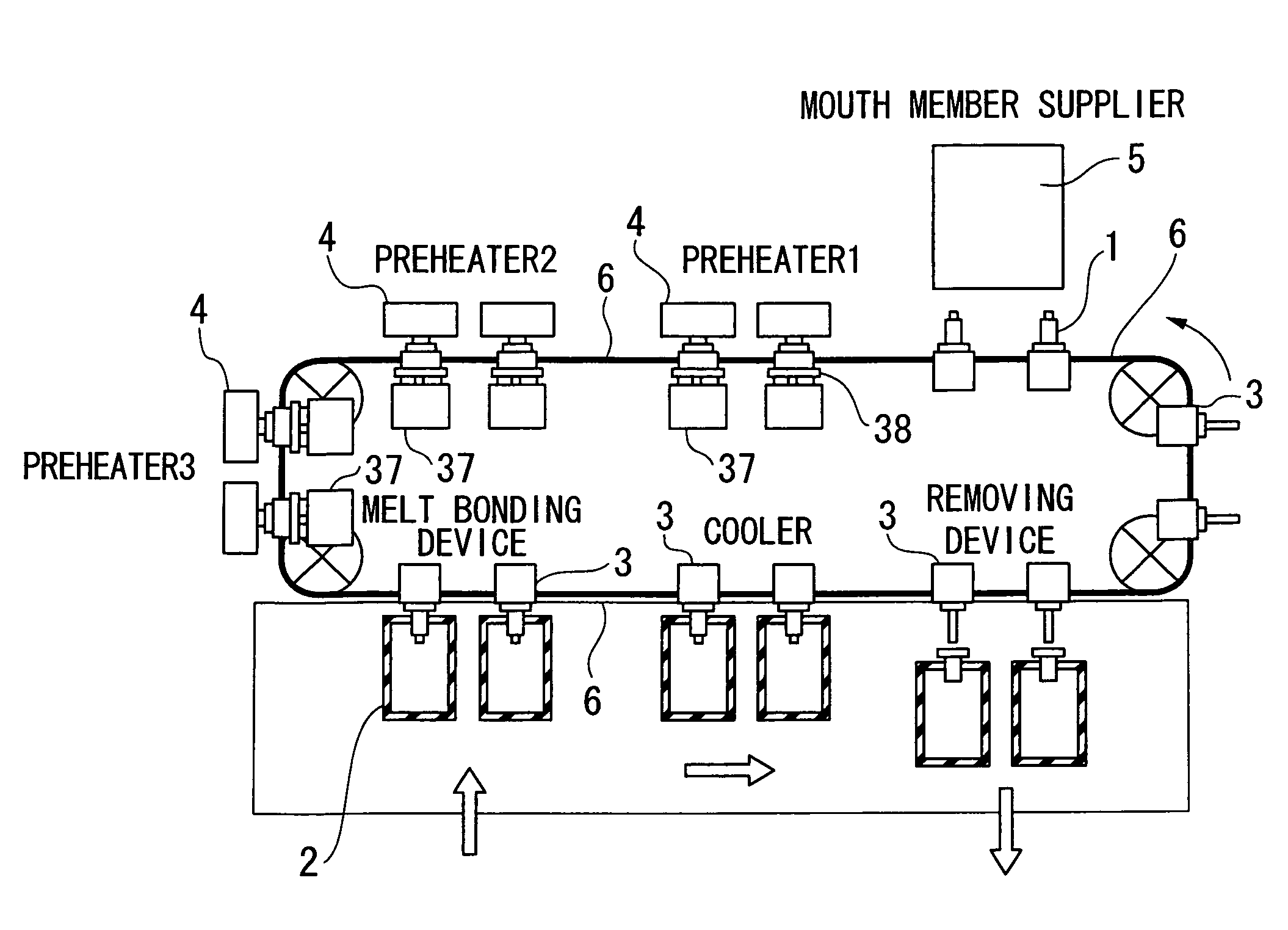

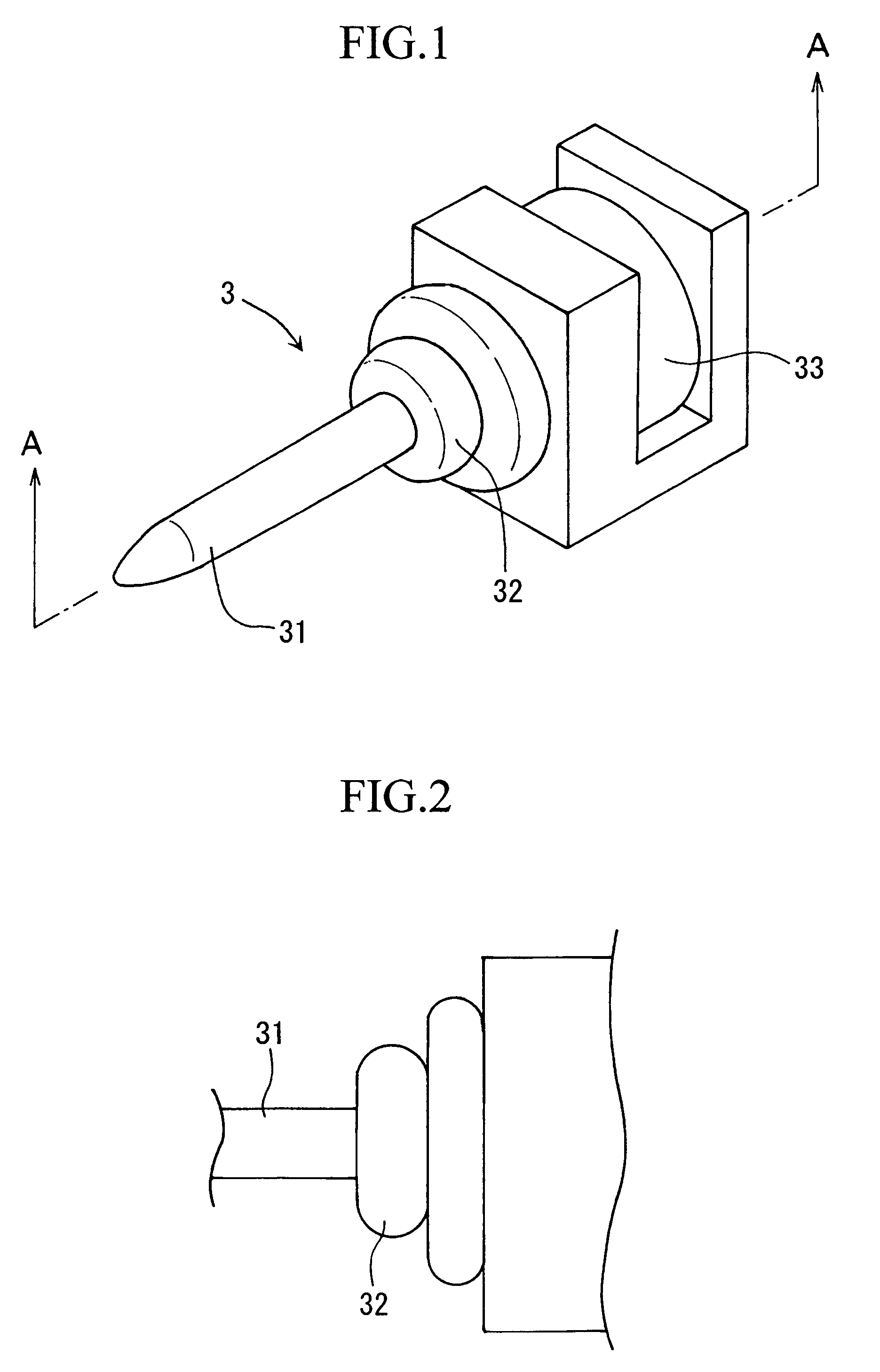

[0084]A mouth member comprising a melt-bonding part having an outer diameter of 13 mm and an inner diameter of 11 mm was produced by injection molding of polyethylene. Also, a bag having a width of 140 mm and a length of 300 mm, in which the outer periphery except for the opening part to be fixed with a mouth member was melt-bonded, was produced from a 300 μm-thick tubular film obtained by inflation molding of polyethylene. From this mouth member and this bag, a bag with a mouth member was produced by using the apparatus shown in FIG. 5.

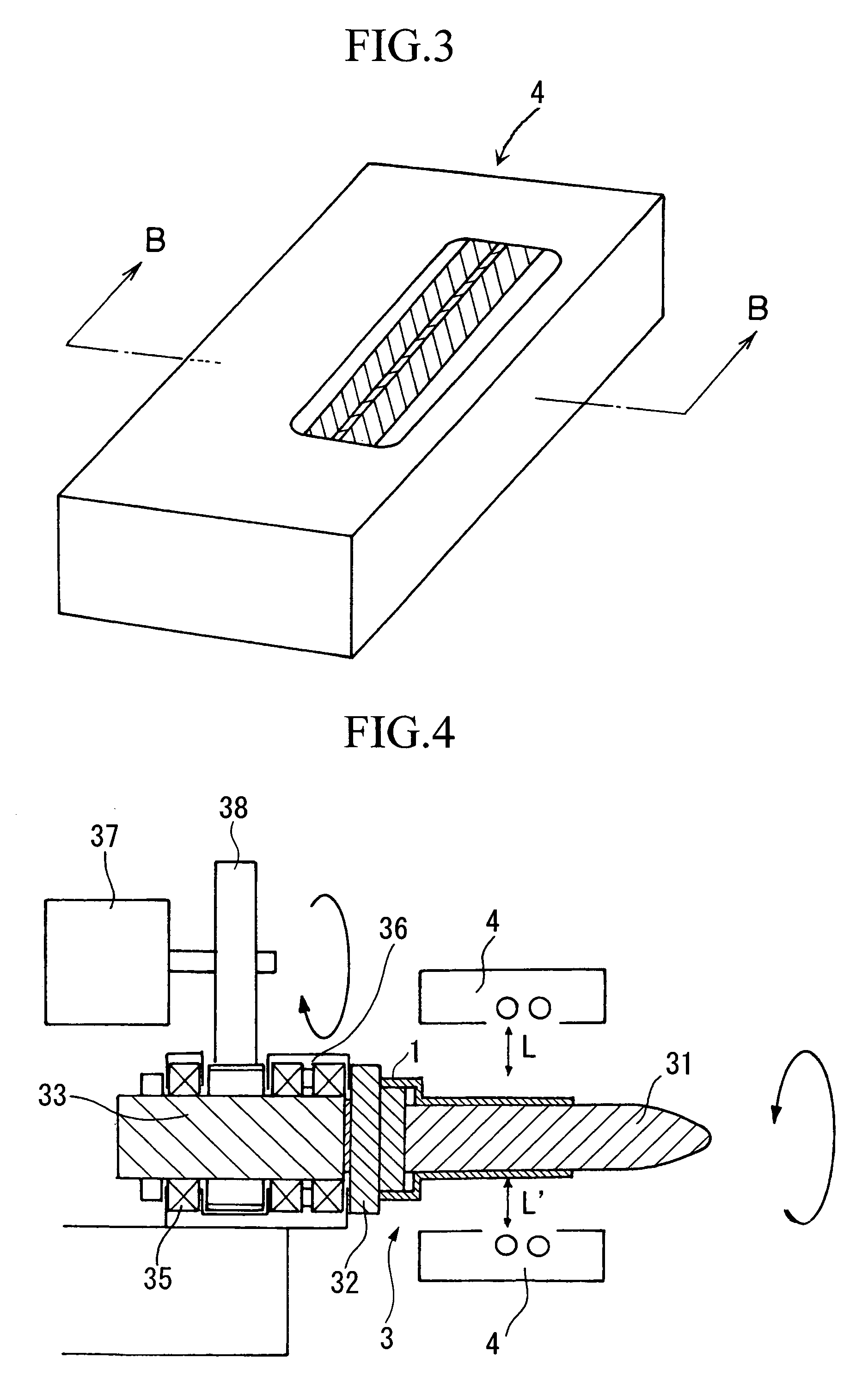

[0085]By using, as the preheater, a heating device in which a linear infrared lamp at a temperature of 600° C. was provided in the upper and lower portions at the position of 3 mm from the surface of the mouth member, the mouth member held on a support member was heated in preheating parts 1 to 3 each for 4 seconds at a rotation speed of 40 rpm. Subsequently, the opening part of the bag was fitted into the heated mouth member in the melt-bonding part...

example 2

[0087]A bag with a mouth member was produced in the same manner as in Example 1 except that a mouth member comprising a melt-bonding part having an outer diameter of 17 mm and an inner diameter of 13 mm was used, a nozzle having an air suction port was used for the support member, and air inside the bag was sucked out from the start of pressing by the sealing mold until the opening of the cooling mold.

[0088]100 Units of this bag with a mouth member were prepared and after filling 500 mL of water into each bag, the bags were tightly plugged, externally pressed to give an internal pressure of 0.07 MPa, and then left standing for 5 minutes. No water leakage was observed in any of the bags with a mouth member.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com