Medical film

a medical film and film technology, applied in the field of medical film, can solve the problems of pain or impair function, difficult follow-up operation with respect to primary disease, and the living body adhesion to one, and achieve the effects of excellent biocompatibility, excellent strength in suturing and bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Manufacture of Fabric Body

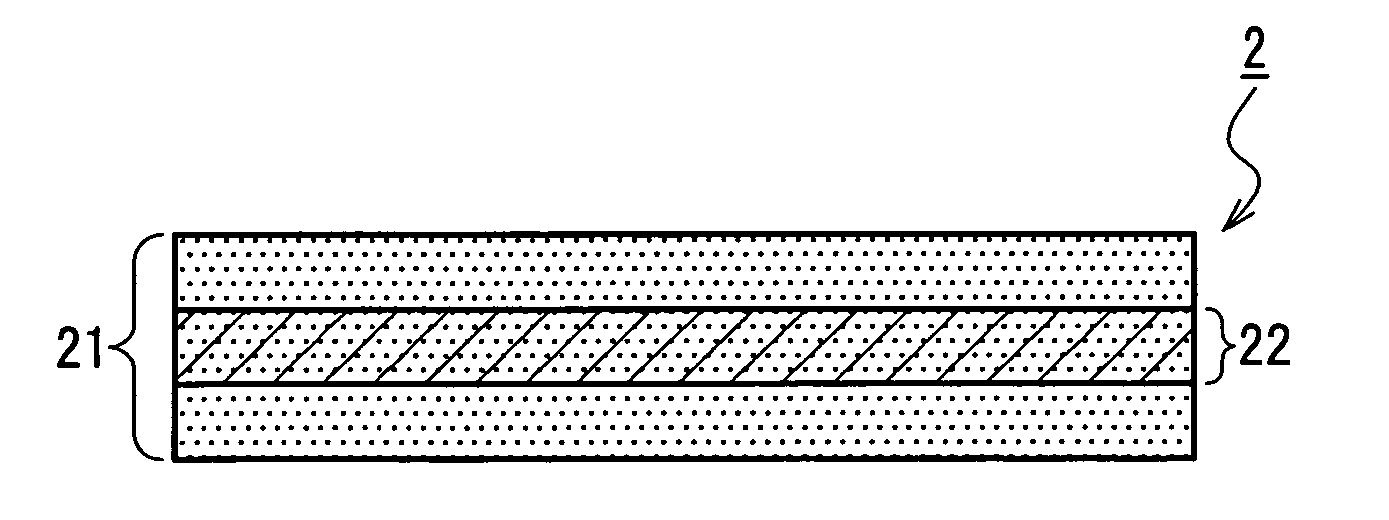

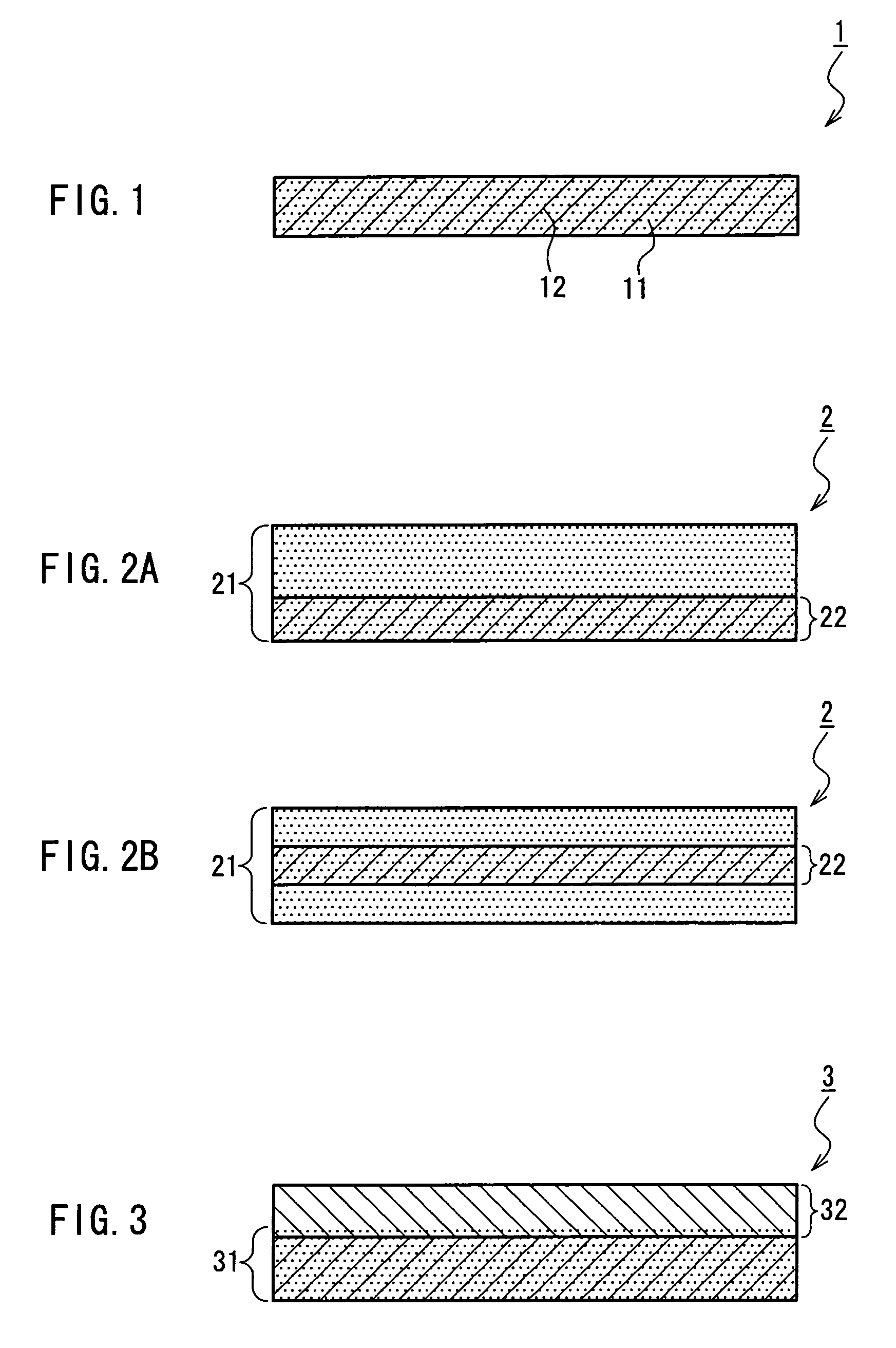

[0106]Using a lactic acid-caprolactone copolymer multifilament yarn (thickness: 42 decitex (dtex)), a twin loop knit (thickness: 200 μm) in which a vertical length and a horizontal length of a unit of stitches were both 3.5 mm and a twin loop knit (thickness: 200 μm) in which a vertical length and a horizontal length of a unit of stitches were both 1.5 mm were prepared. The “dtex” (decitex: 1 dtex=1.111×1 denier) is a thickness unit according to the International System of Units (SI). As described above, FIG. 7 illustrates a schematic diagram of a knit stitch structure of a twin loop knit. Each of the twin loop knit fabric bodies was held between two glass plates and subjected to a vacuum heat treatment at 120° C. for 3 hours. Subsequently, each of the heat-treated twin loop knit fabric bodies was subjected to a plasma treatment at room temperature, in oxygen gas at 67 Pa (0.5 torr), with 50 W, for 30 seconds.

Integration with Gelatin Film

[0107]Each of the f...

example 2

[0121]As fabric bodies, complex films were prepared using a twin knit and a warp knitted fabric shown below, respectively, and the strength of the thus-obtained films were determined. Note here that a lactic acid-caprolactone copolymer multifilament yarn used for the preparation of the films was prepared using lactic acid-caprolactone copolymer containing lactide (a dimer of lactic acid) and caprolactone at a composition ratio (a molar ratio) of 75:25 by a known method (see JP 8(1996)-317968 A, for example).

Reinforcing Material

[0122](Twin Knit 2-1)

[0123]Using a lactic acid-caprolactone copolymer multifilament yarn (thickness: 75 decitex (dtex)), a twin loop knit in which a vertical length of a unit of stitches was 2.7 mm and a horizontal length of the same was 3.1 mm was prepared. FIG. 10A is a photograph showing a knit stitch structure of the twin knit 2-1 (25× magnification).

[0124](Twin Knit 2-2)

[0125]Using a lactic acid-caprolactone copolymer multifilament yarn (thickness: 67 dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| horizontal length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yarn threading tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com