Method for monitoring a polymerization in a three-dimensional sample

a three-dimensional sample and polymerization technology, applied in chemical methods analysis, material heat development, instruments, etc., can solve the problems of composite polymeric materials that are not readily analyzed using thin films, take longer to reach peak temperatures of three-dimensional samples, and retain heat longer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

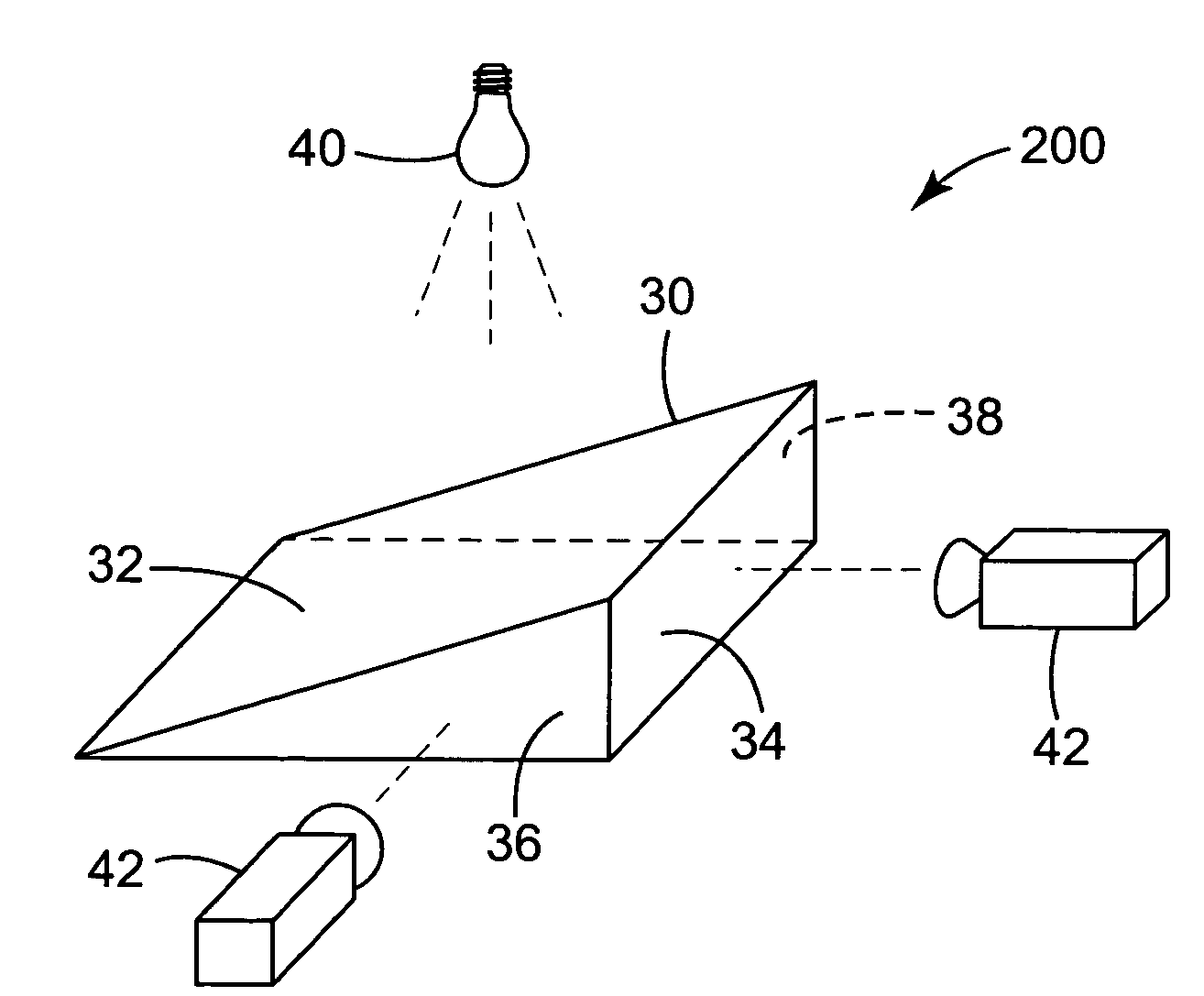

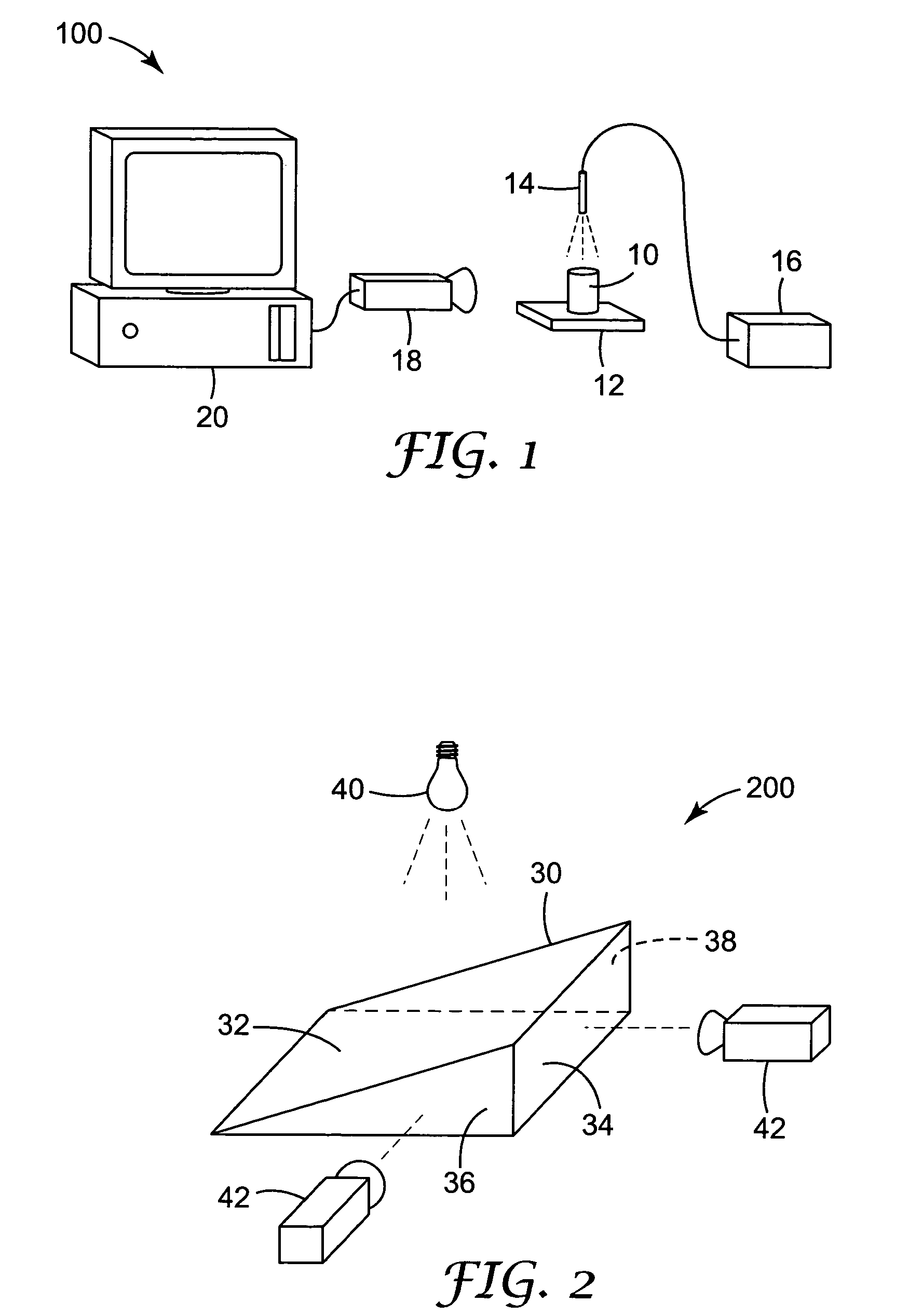

[0115]A cylindrical sample (6 mm×1 mm, 75 mg) of Z250 was placed on a glass slide and photocured using a Visilux 2™ Dental Blue light gun (available from 3M Dental Products Division, St. Paul, Min.) held approximately 1 centimeter directly above the sample. A Prism DS™ infrared camera with a 25 millimeter lens (Flir Systems, Boston, Mass.) was held about 46 centimeters (18 inches) away from the sample and temperature data was collected at approximately 10-second intervals. The temperature of the upper surface of the sample as a function of irradiation time is shown in Table 1 below.

[0116]

TABLE 1Elapsed TimeTemperature(seconds)(° C.)033.31233.71837.92336.42735.93435.53935.14534.85034.55634.56234.56934.47434.6

example 2

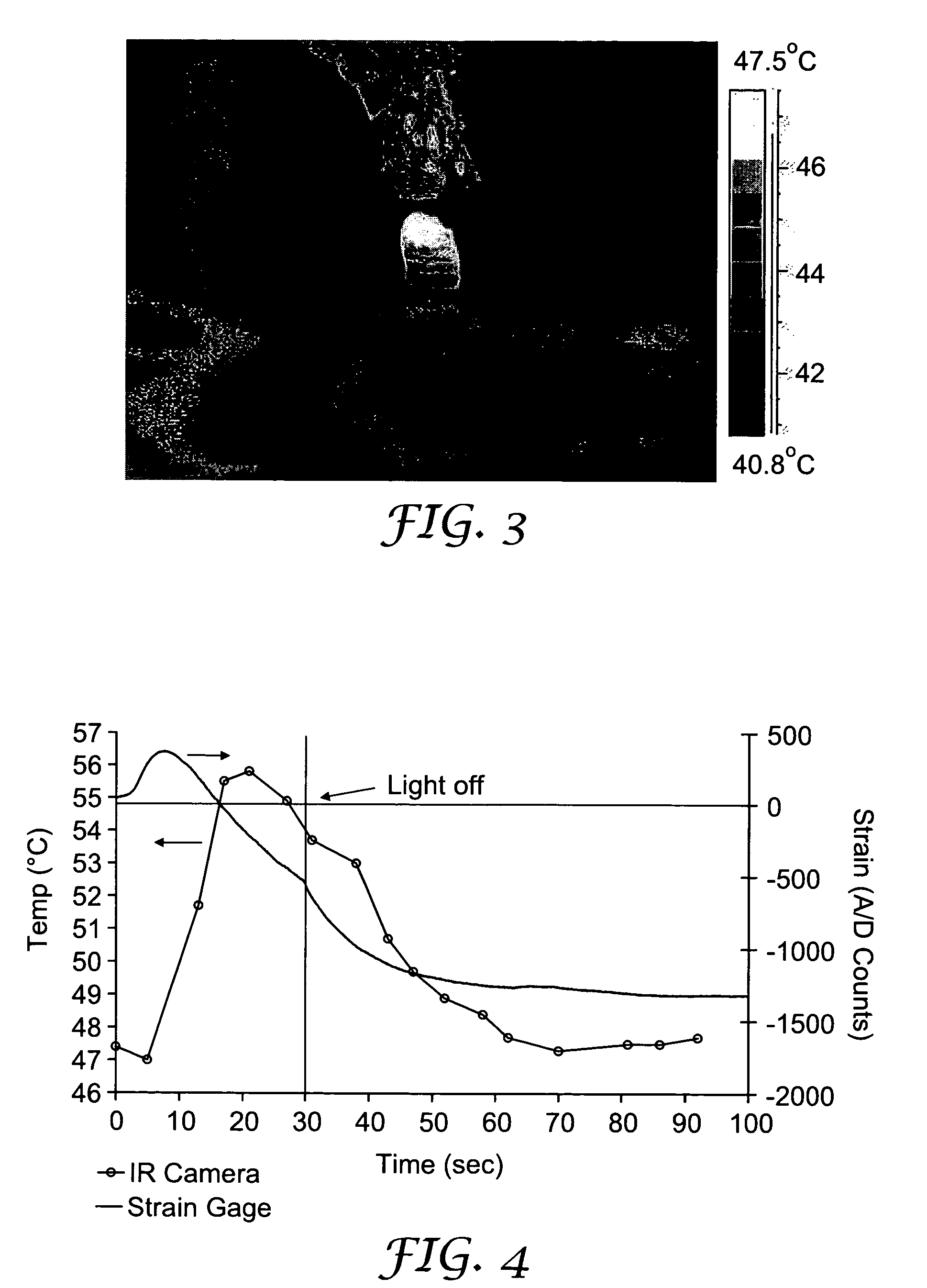

[0117]A small disc (6 mm×1 mm, 75 mg) of Z250 was placed on a CEA-06-062WT-120 strain gage (Vishay Measurements) and photocured using a Visilux 2 dental light gun held about 1 centimeter directly above the sample. Irradiation was carried out for 30 seconds. Upon photocuring, shrinkage caused the strain gage to curl up resulting in a signal in the strain gage that is recorded by a computer. The temperature of the sample was simultaneously monitored using a Prism DS camera held about 46 centimeters (18 inches) away from the sample on a tripod. The temperature and strain profile of the sample as a function of irradiation time are shown in Table 2 below. Data from the CEA-06-062WT-120 strain gauge was collected by a Model 5100A Scanner (Vishay Measurements) interfaced with a IBM compatible PC using a Model 5101 PCI Interface Card (Vishay Measurements). Analysis of the digitized signal was done using StrainSmart 5000 software (version 3.10, Vishay Measurements) and is presented in Table ...

example 3

[0119]The curing kinetics of a thick section of a composite formulation were studied by recording the heat propagation through the mass using a Prism DS camera. A sample of Z250 was shaped by hand into approximately a cylinder with dimensions 10.9 millimeters×6.7 millimeters. This cylinder was irradiated from the top with a Visulux dental blue light gun (Model 5560) fitted with an aperture of less than 1 millimeter by wrapping the tip of the light gun in perforated aluminum foil to reduce the intensity of light. The gun was held about 1 millimeter from the top of the cylinder to ensure that there was no irradiation of the sides of the cylinder. The thermal imaging camera was held normal to the axis of the cylinder, and upon irradiation the propagation of the exotherm down the axis of the cylinder was observed for 250 seconds at various points along the length of the cylinder. Temperature changes at each time point were obtained by subtracting the original image from all subsequent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com