Contact grid array system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

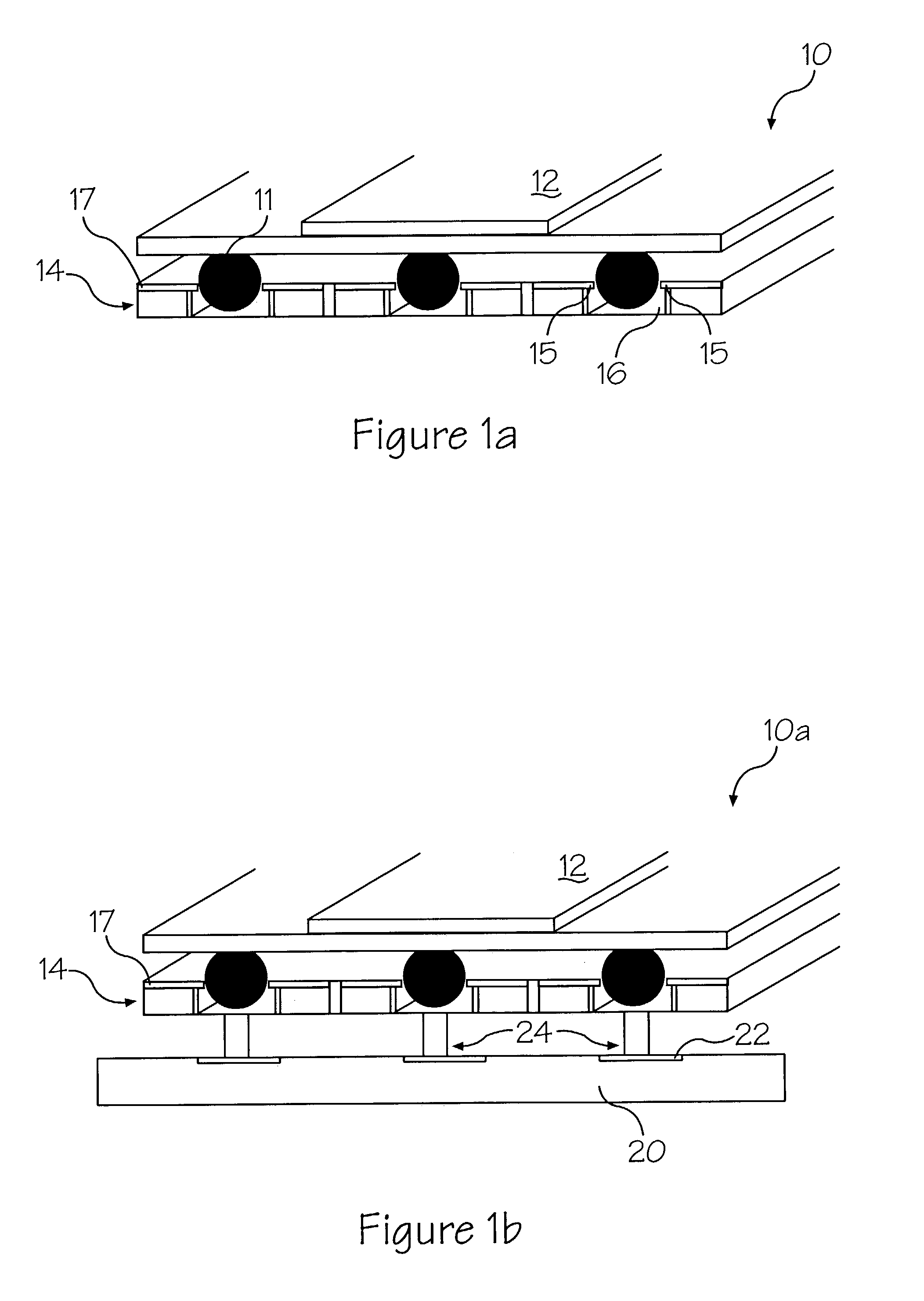

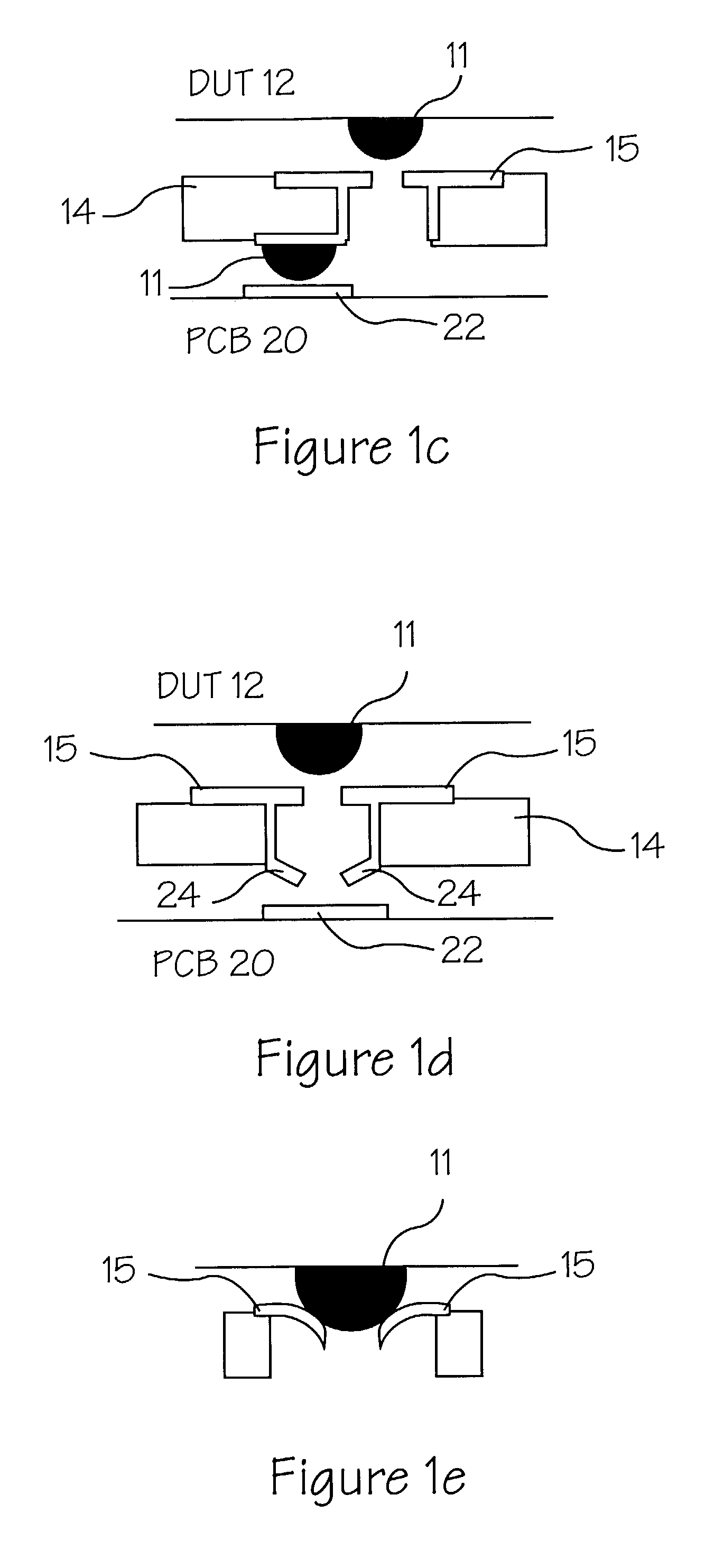

[0080]Generally speaking, the invention features a scalable, low cost, reliable, compliant, low profile, low insertion force, high-density, separable and reconnectable electrical connection for high speed, high performance electronic circuitry and semiconductors. The electrical connection can be used, for example, to make electrical connections from one PCB to another PCB, MPU, NPU, or other semiconductor device.

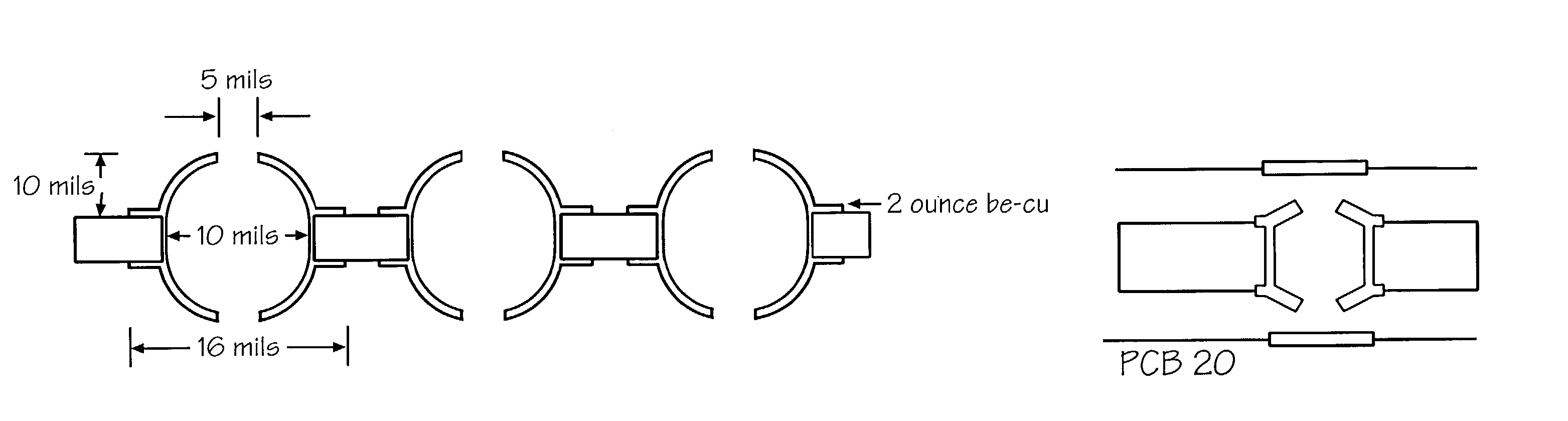

[0081]The invention comprises a connection system consisting of a beam land grid array (BLGA) or a ball beam grid array (BBGA). The electrical and mechanical functionality of the BLGA and / or BBGA lends itself to numerous applications in the electronics space. It allows for short interconnections to be established between almost any electrical contact surfaces, thus maintaining high electrical performance. Some suitable applications include test, burn-in, prototyping, and full wafer burn-in applications, which require high electrical performance. Optimized electrical, thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com