Closing device on a plastic injection molding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The invention is now explained more detailed by way of example with reference to the accompanying drawings. However, the embodiments are only examples which should not restrict the inventive concept to one specific disposition.

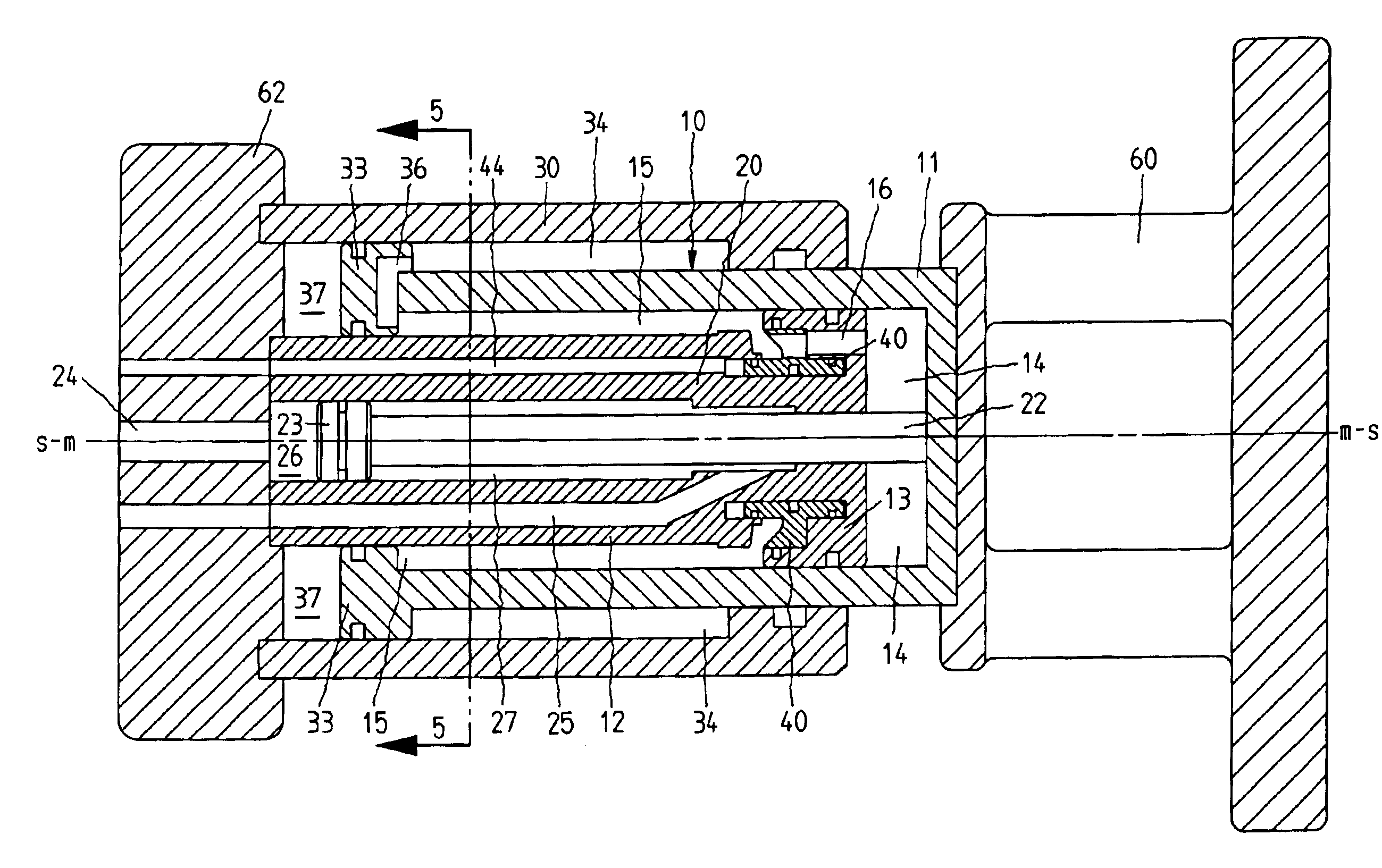

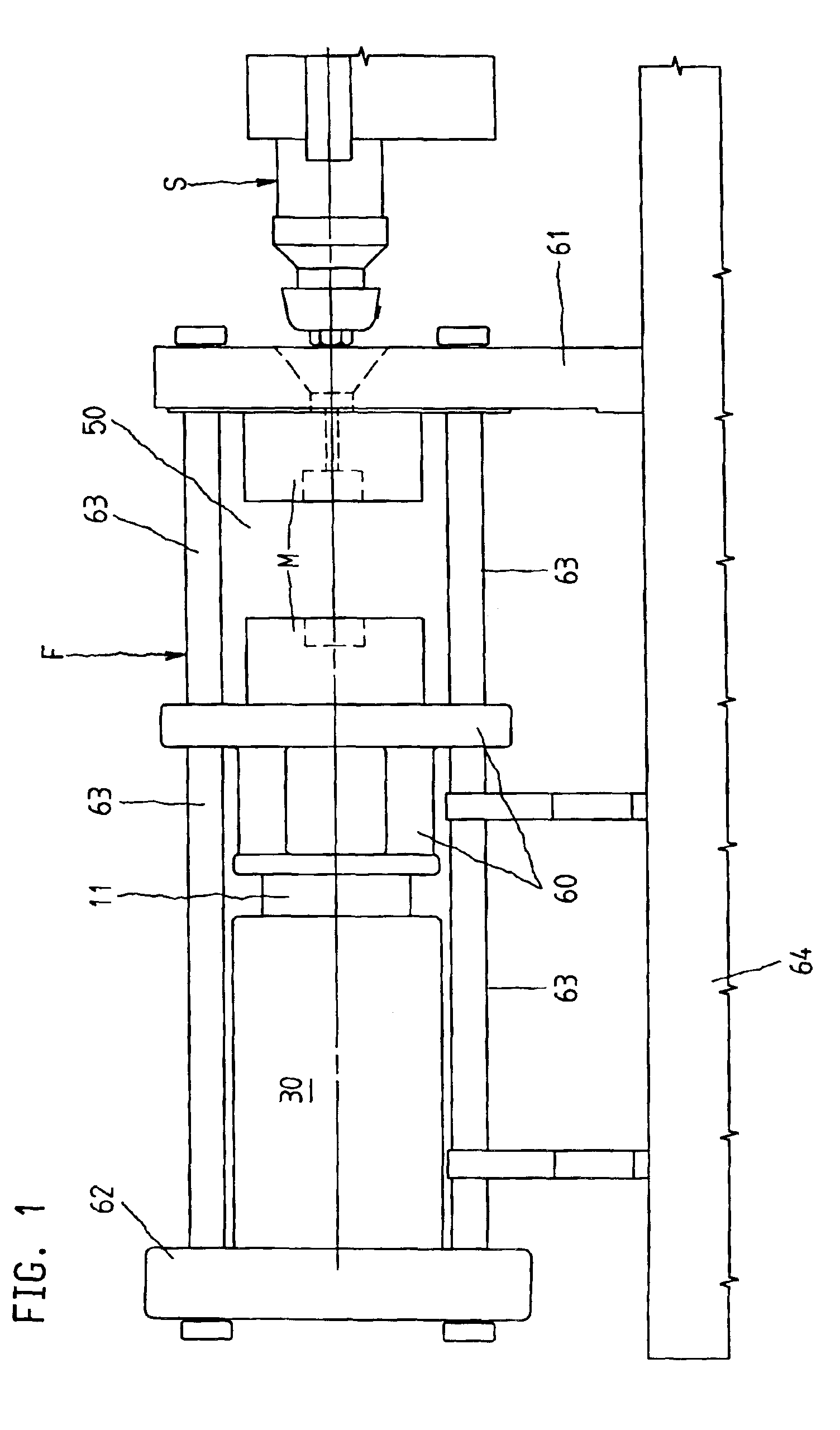

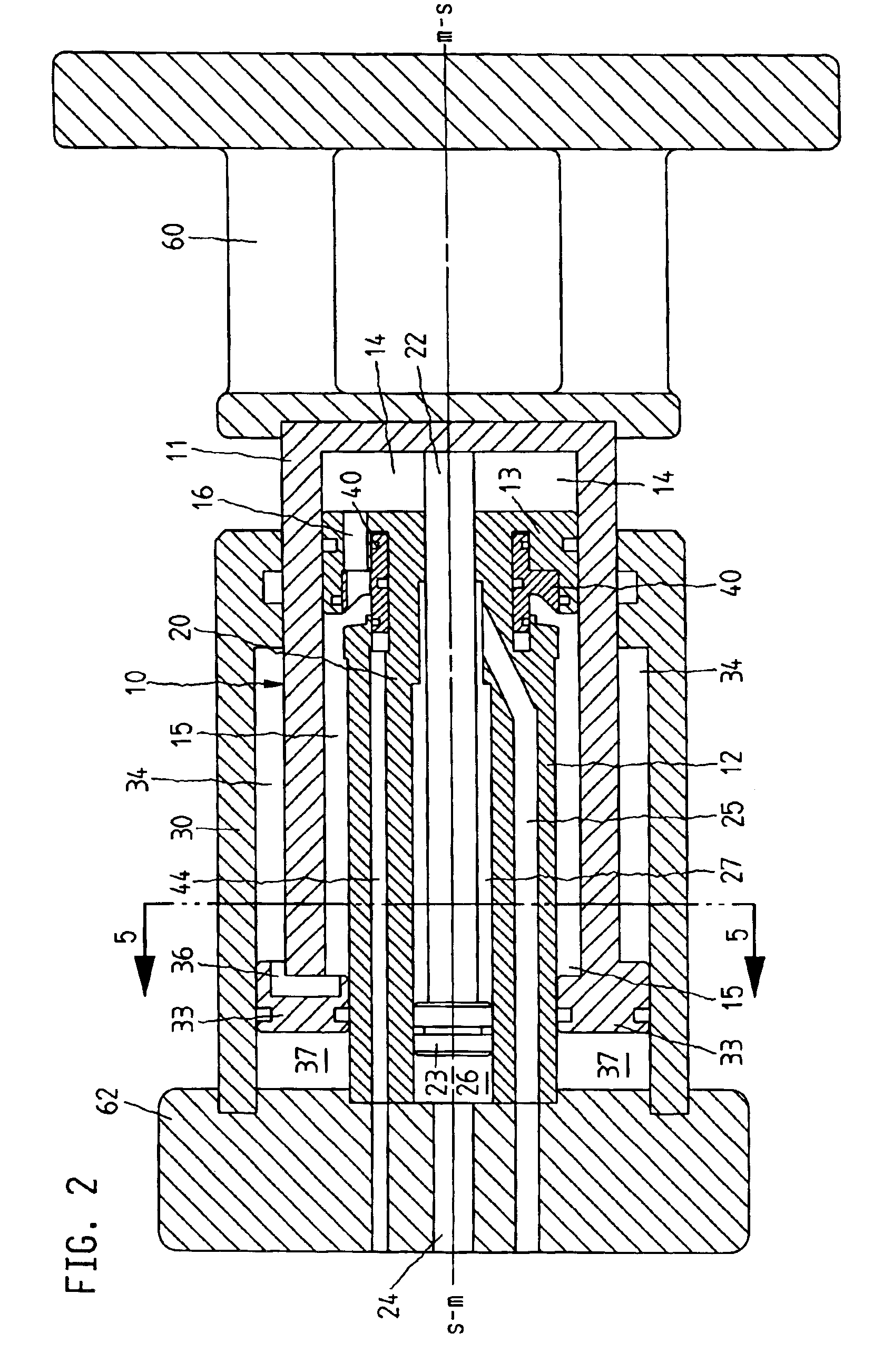

[0017]FIG. 1 illustrates the closing device for a mold dosing unit F of a plastic injection molding machine for processing plastics materials and other plasticizable substances, such as, for example, pulverulent substances or ceramic substances. The mold closing unit F is supported on a machine base 64 and includes a stationary mold carrier 61, a movable mold carrier 60, and a supporting element 62. The closing device is supported on the supporting element 62, of which device FIG. 1 illustrates the externally situated compensating cylinder 30 and the pressure cylinder 11, which serves as the piston for this compensating cylinder. During actuation of the pressure cylinder unit, which is to be discussed more fully hereinafter, the movable mold carrier 60 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com