High aspect ratio, microstructure-covered, macroscopic surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

HARMs Fabricated on a Cylindrical Shaft

The novel process has been used to fabricate HARMs on a nickel cylinder of diameter 1.0 cm. A square-grid mask was used to lithographically pattern a free-standing sheet of PMMA of thickness 300 .mu.m using the CAMD synchrotron x-ray radiation source. The nickel cylinder was placed vertically on a hot plate and brought to a temperature of approximately 100.degree. C. The exposed PMMA sheet was held above the same hot plate until it became flexible, at which point it was wrapped around the cylinder and secured with a clamp. The cylinder was removed from the hot plate and cooled to room temperature. Because the thermal expansion coefficient of PMMA is greater than that of nickel, the PMMA shrink-fit onto the nickel cylinder.

The PMMA was then developed by immersing the PMMA-coated nickel cylinder into GG developer (V. Ghica and W. Glashauser, "Verfahren fur die Spannansfreie Entwicklung von Bestrahlten Polymethyl-methacrylat-Schichtyen," Offenlegu...

example 3

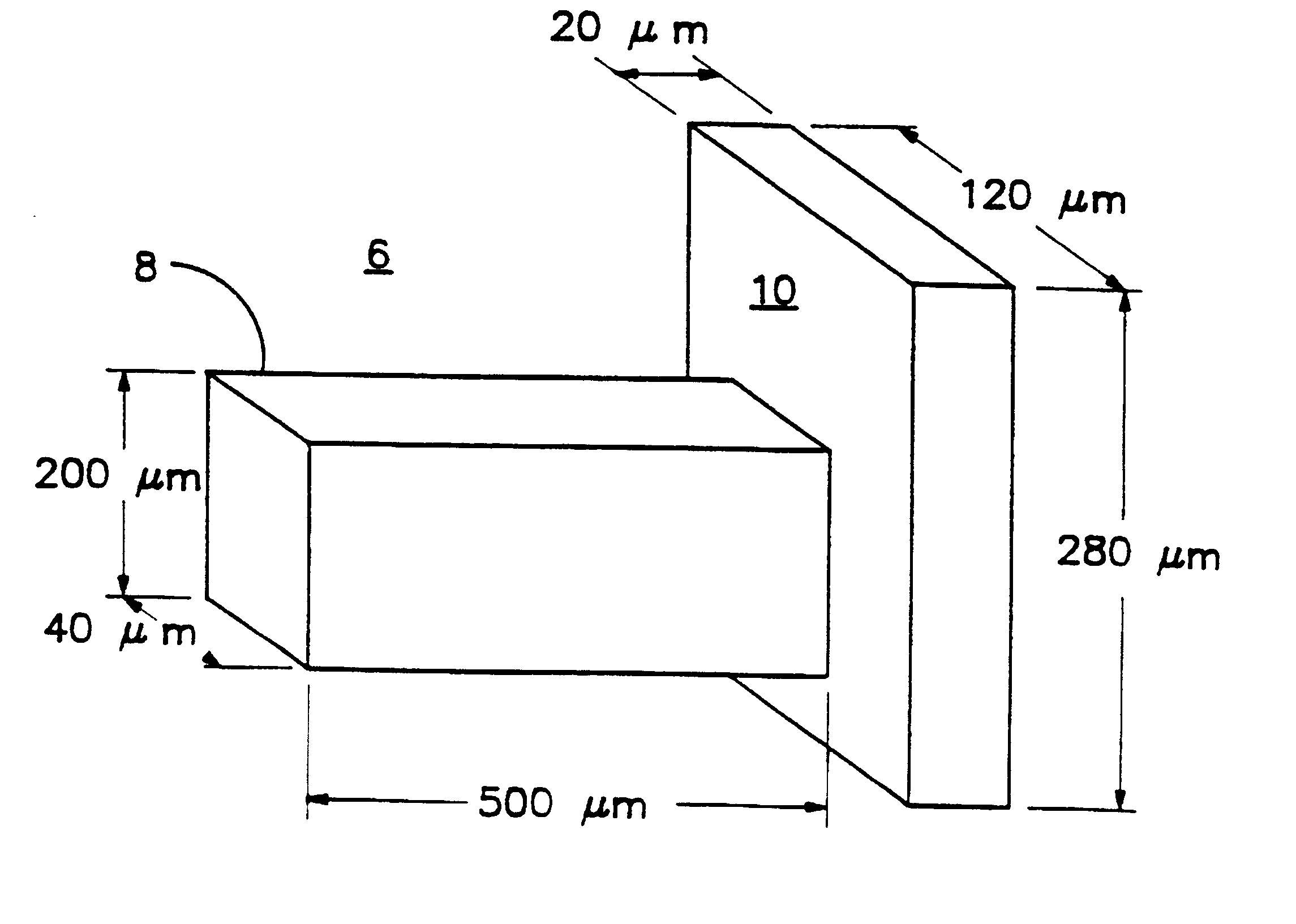

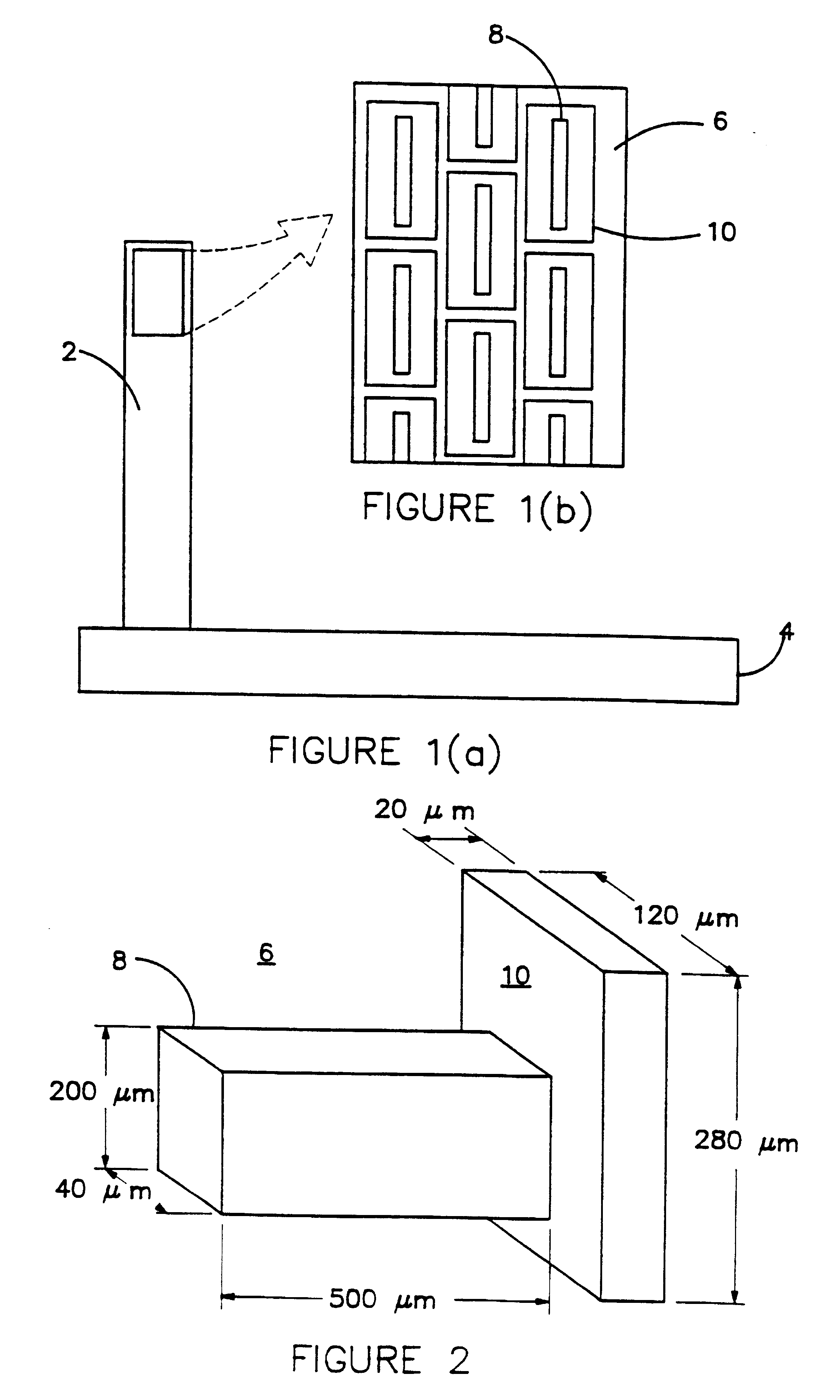

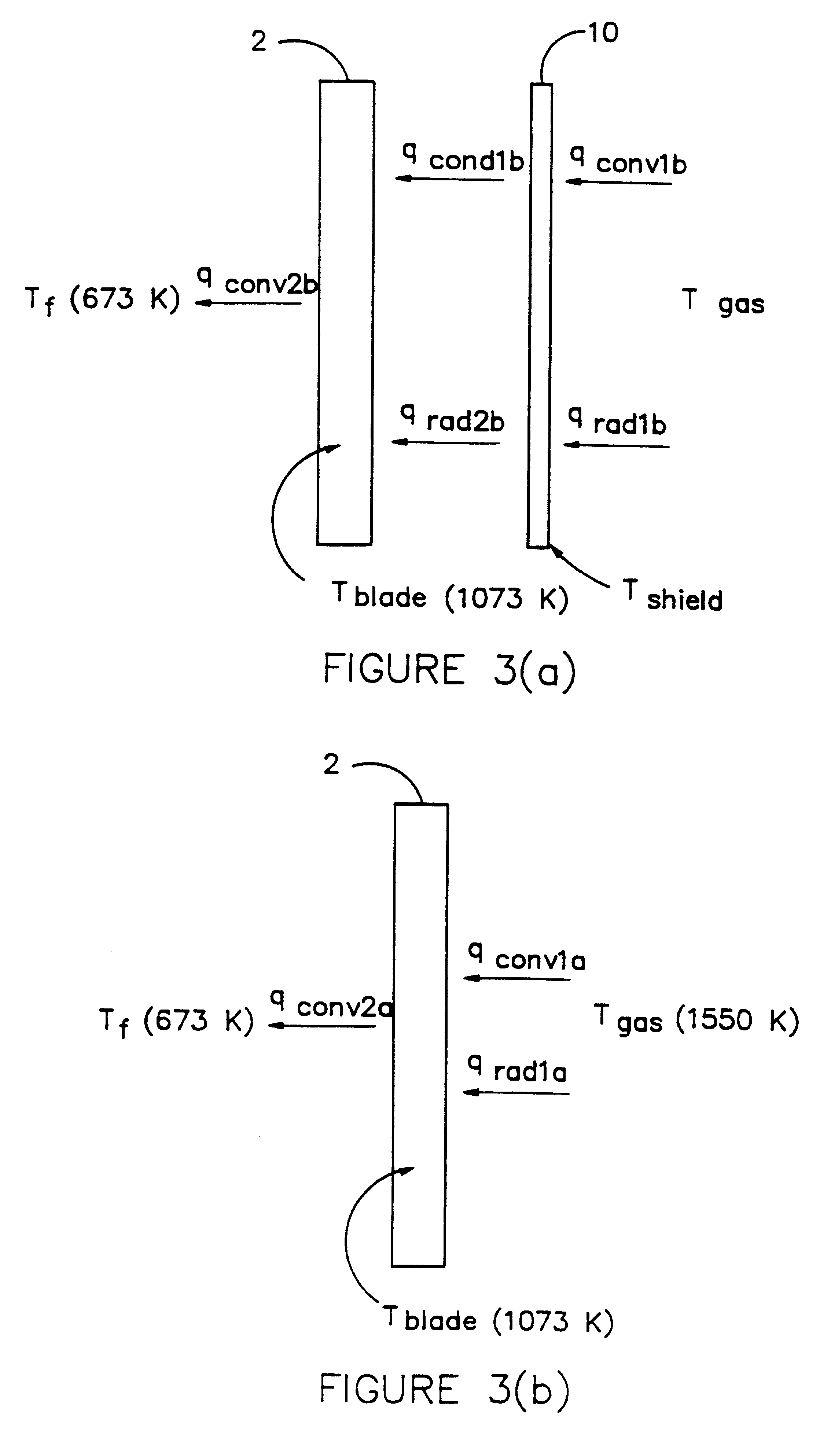

Thermal banners; application to turbine blades

In one embodiment, thermal barrier microstructures will be manufactured on a turbine blade. A mold insert will be manufactured to mold or emboss a pattern of microstructures into a thin film of polymer as described above. The polymer film, containing voids where structures in the mold insert were present, is applied to the blade surface. An electroplating process then fills voids in the polymer with metal, thereby building a field of microstructures on the blade surface. By overplating beyond the height of the polymer, caps can be grown on top of the posts if desired; if the caps are allowed to grow large enough, they can form a continuous wall connected to the substrate by numerous microposts. Following the electroplating process, the polymer film is removed, for example with a solvent, leaving a metallic microstructure canopy on the surface.

It is preferred that there be a smooth transition from a material at the base of the microstruct...

example 4

Prototype Manufactures

In one prototype, "mushroom" shaped canopies were manufactured 300 .mu.m tall, with 170.times.170 .mu.m square posts, topped by square canopies 300 to 300 .mu.m in diameter at the base.

A 0.1 .mu.m-thick nickel film, deposited from a modified Watts bath, adhered well to a silicon wafer. The composition of the modified Watts bath was as follows: NiSO.sub.4. 6H.sub.2 O (300 grams / liter), NiCl.sub.2.6H.sub.2 O (45 grams / liter), boric acid (45 grams / liter), sodium lauryl sulfate (0.3-0.5 grams / liter), saccharin (0.5-1.0 grams / liter), coumarin (0.5 grams / liter), pH 2.0, temperature 55.degree. C. The sodium lauryl sulfate acted as a surfactant, and the saccharin acted as a stress reliever to help produce fine grains. The anode was a nickel foil. High current densities of 0.1 to 0.2 A / cm.sup.2, corresponding to a nickel deposition rate of 100-150 .mu.m / hour, lowered the time required to electroplate the 490 .mu.m tall nickel prototype structures to just four hours. Pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

| Microstructure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com