Fluid-assisted thermal management of evaporation sources

a technology of evaporation source and thermal management, which is applied in the field of thermal evaporation, can solve the problems of less effective coupling heat into evaporation source operation, process loss, etc., and achieve the effects of high thermal mass, simplified control of thermal evaporation process, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

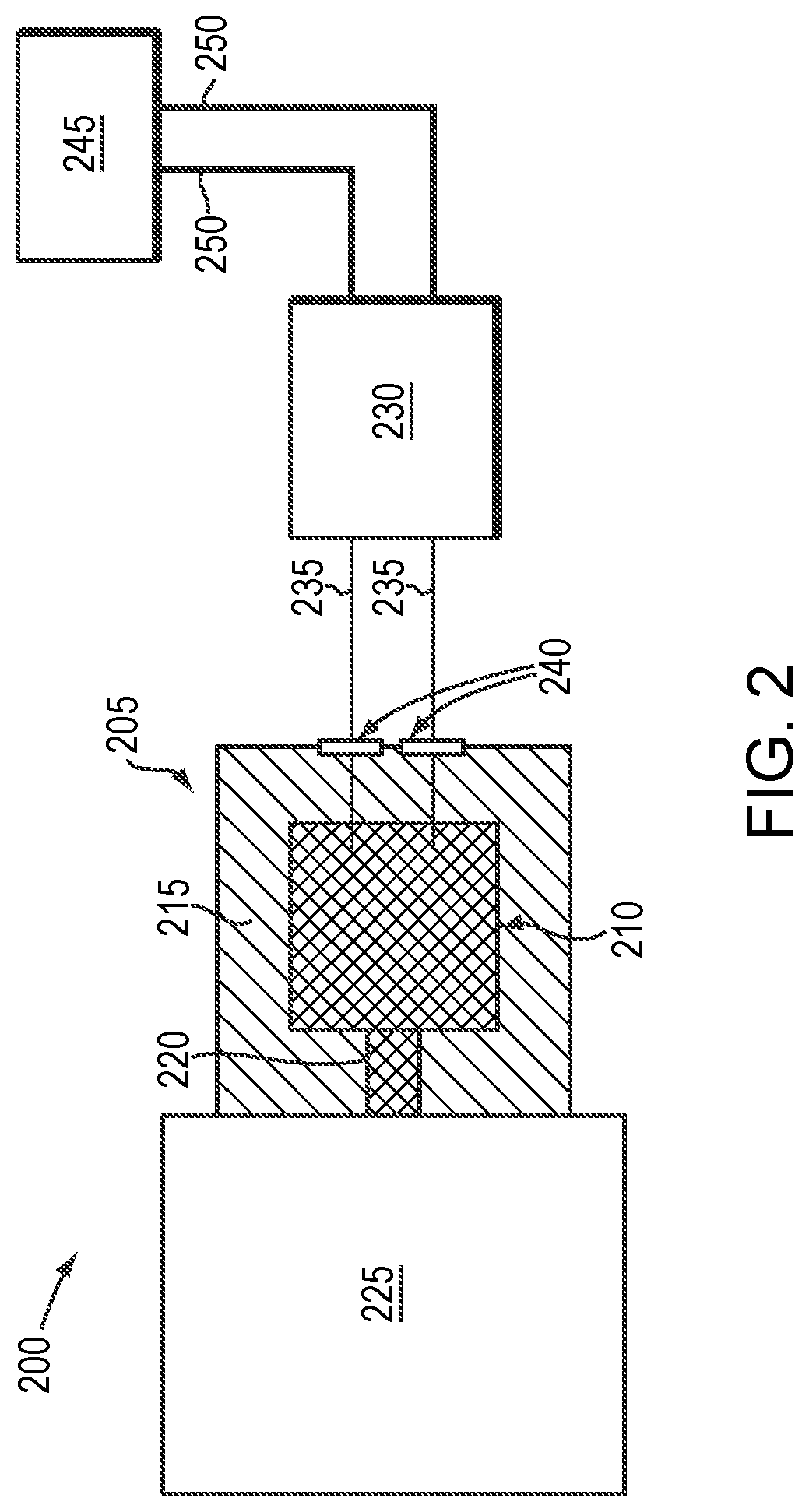

lass="d_n">[0039]FIG. 2 is a schematic diagram of an exemplary deposition system 200 in accordance with embodiments of the present invention. As shown, the system 200 features a thermal evaporation source 205 incorporating a reservoir 210 for feedstock material to be evaporated. The reservoir 210 is at least partially surrounded by a vacuum shell 215 that enables the establishment and maintenance of very low pressures (i.e., very high vacuums) in the deposition system 200. The source reservoir 210 has an evaporation port 220 through which the evaporant leaves the source 205 and enters a deposition chamber 225 for, e.g., deposition on one or more substrates. While only one evaporation source 205 is depicted in FIG. 2 for simplicity, embodiments of the present invention utilize two or more evaporation sources (e.g., for evaporation of different materials). Multiple evaporation sources may share a single fluid-based thermal management system, or each evaporation source may utilize its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com