Golf ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

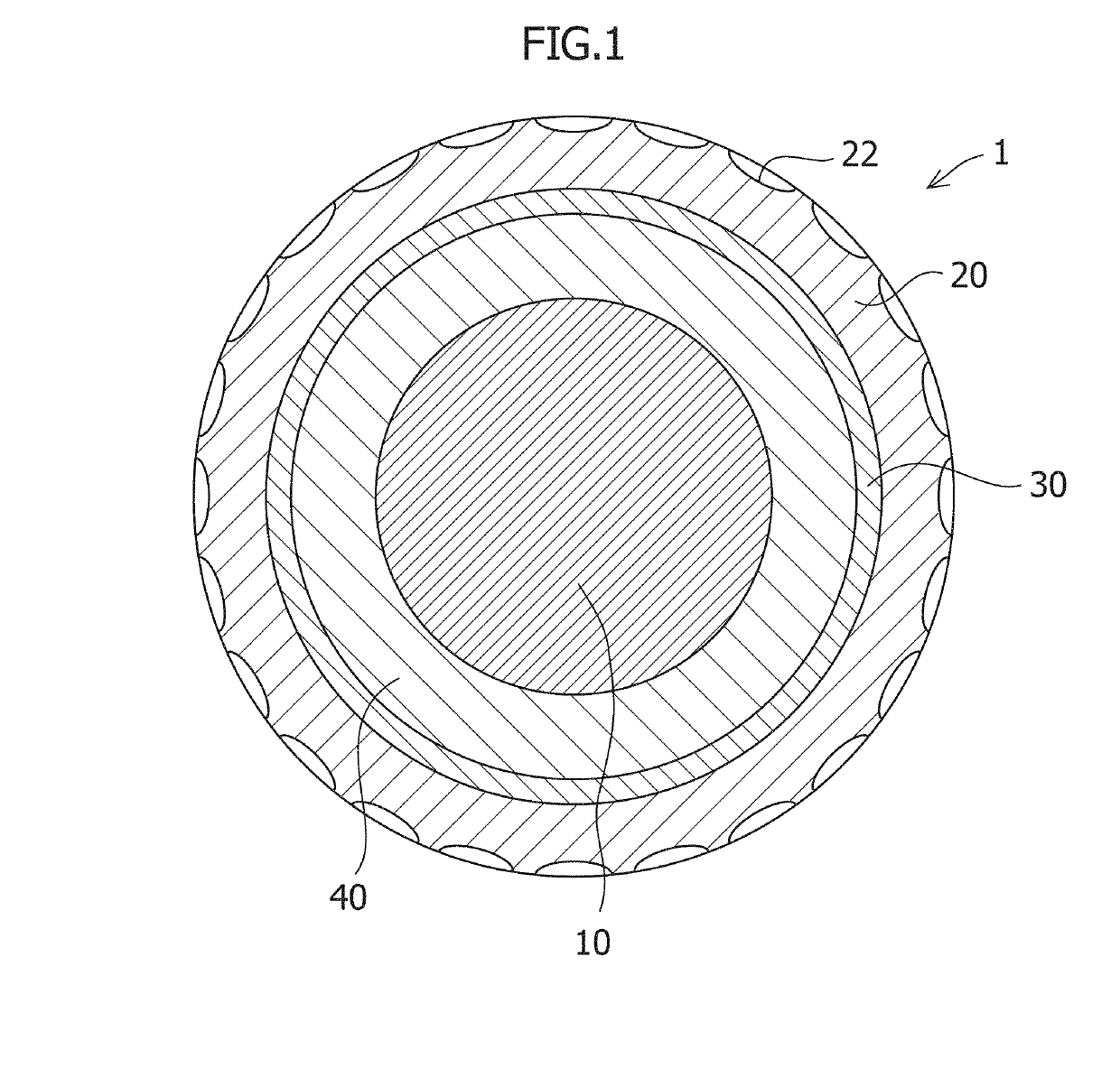

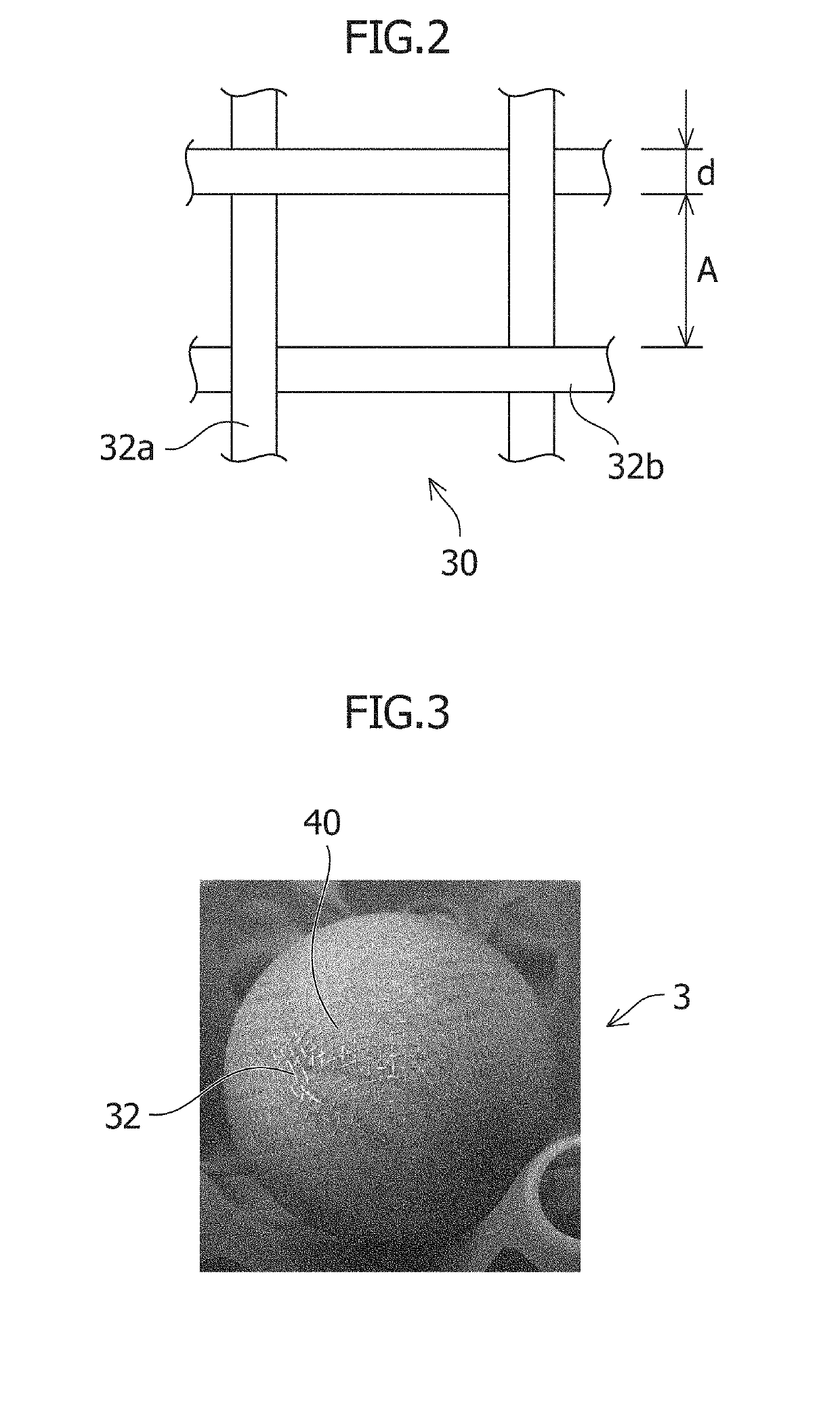

[0046]The golf balls of Examples and Comparative Examples having the constitutions shown in Table 1 were prepared, and the tests for measuring the performances of the prepared golf balls were performed. The compositions of the materials of the cores shown in Table 1 are shown in Table 2, and the compositions of the materials of the intermediate layers and the covers are shown in Table 3. It is to be noted that the mixing amounts of the individual components in Table 2 and Table 3 are represented in terms of parts by weight. The metal mesh layers of Examples were all made of the same metal, stainless steel. In addition, in all of Examples and Comparative Examples, the covers having the same dimple arrangement were formed. In addition, each of the golf balls was prepared by regulating the core composition in such a way that the deflection hardness was 2.5 mm, the outer diameter was 42.7 mm, the weight was 45.4 g, and the USGA initial velocity was 77 m / s.

TABLE 1ExamplesComparative Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com