A kind of disc-shaped suspension porcelain insulator processing equipment

A porcelain insulator and shape suspension technology, which is applied in the field of disk suspension porcelain insulator processing equipment, can solve the problems of porcelain insulators such as insufficient ability to eliminate pores, and achieve the goal of improving steep wave performance, improving degassing effect, and ensuring uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

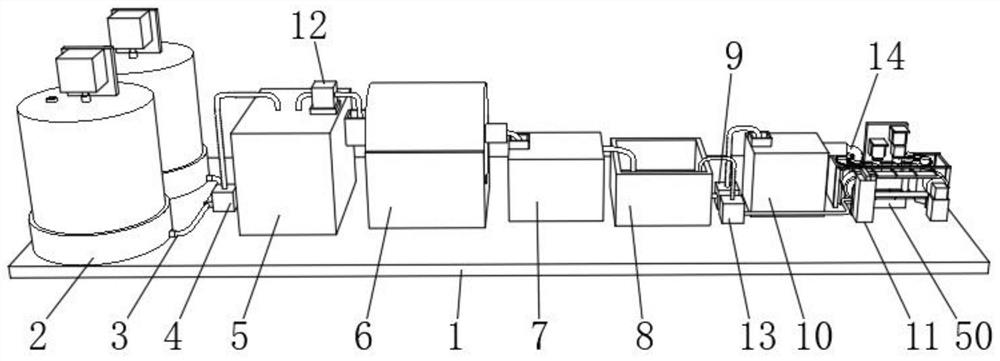

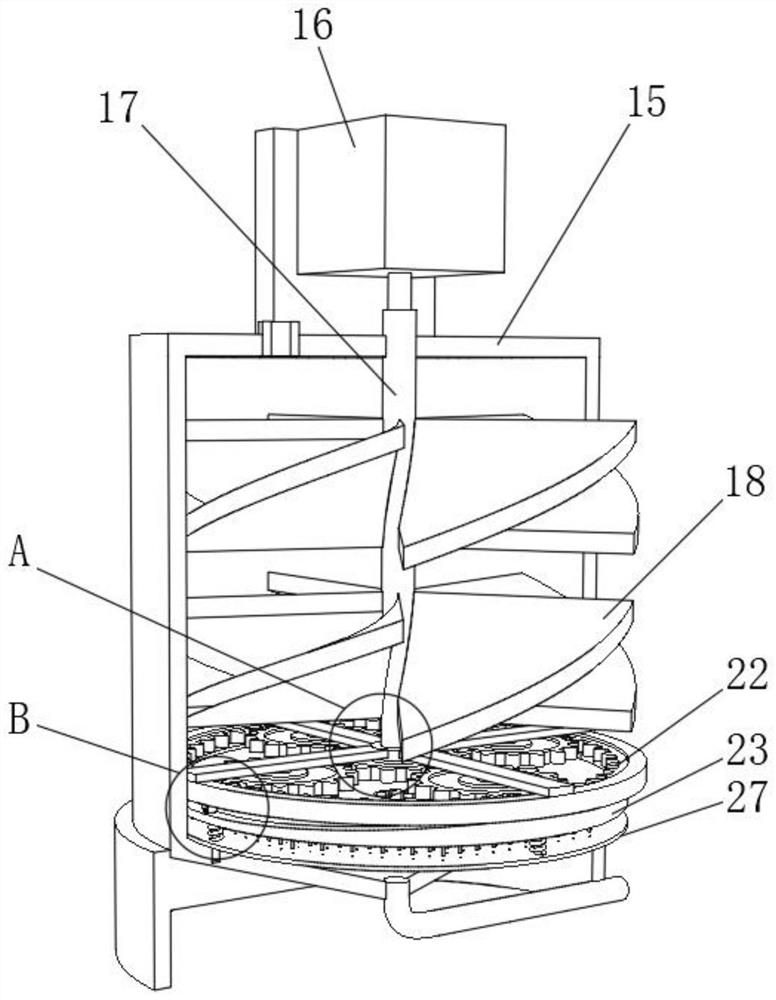

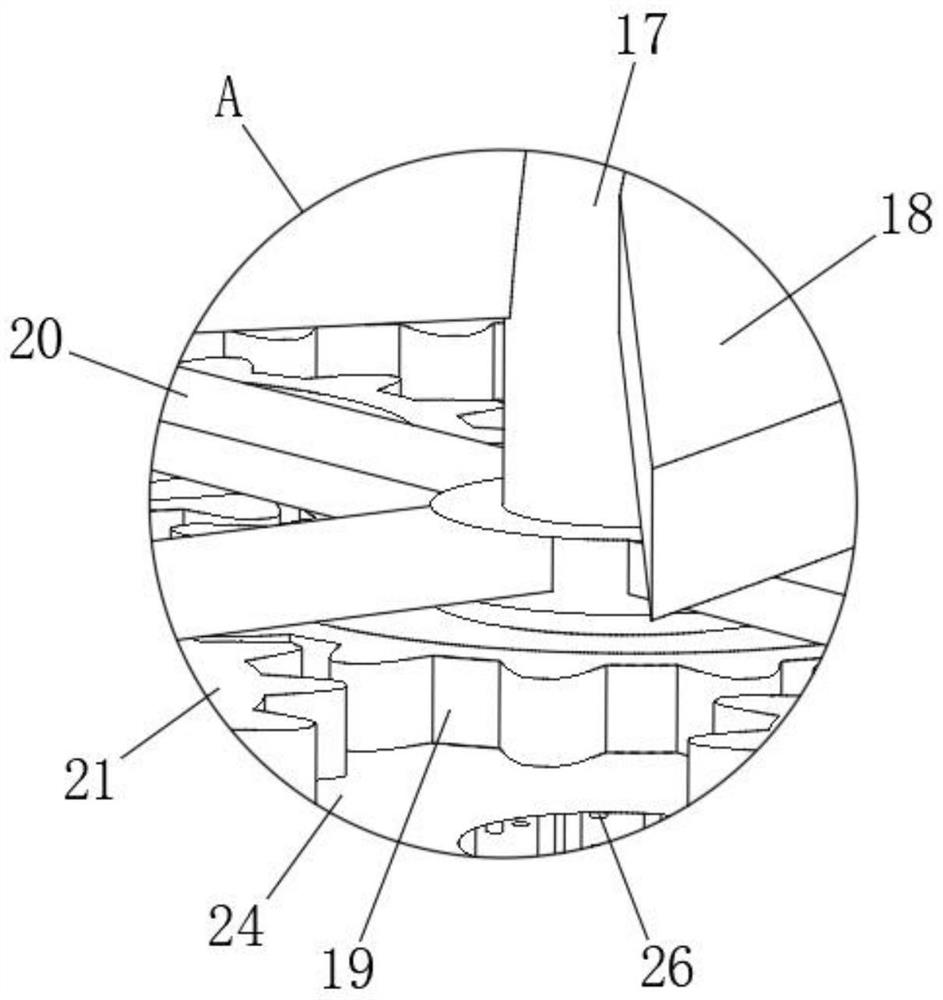

[0030] like Figure 1-9 As shown, the embodiment of the present invention provides a disc-shaped suspension type porcelain insulator processing equipment, including a base 1, a stirring mill 2 is provided on the front and rear sides of the top of the left end of the base 1, and the stirring mill 2 includes an abrasive tank 15, a first Motor 16, rotating shaft 17, first gear 19, cross 20, second gear 21, ring gear 22, dredging plate 23, annular groove 25, thin rod 26, sieve plate 27, guide rod 28, spring 29 and roller 30, abrasive The tank 15 is fixedly connected to the top of the base 1, the top of the abrasive tank 15 is fixedly connected with a first motor 16, the output end of the first motor 16 is fixedly connected with a rotating shaft 17, and the outer side of the bottom end of the rotating shaft 17 is fixedly connected with a first gear 19, the rotating shaft 17 A cross 20 is rotatably connected to the outer side of the bottom and the cross 20 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com