Polyamide fiber with improved comfort management, process thereof and article made therefrom

a polyamide fiber and comfort management technology, applied in the field of polyamide fiber with improved comfort management, process thereof and articles made therefrom, can solve the problems of post-chilling effect, reduced comfort, and moisture may remain after cessation of activity, so as to improve the hydrophilic behavior of hydrophobic textiles, improve the handle and softness of the fiber, and reduce the flexural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

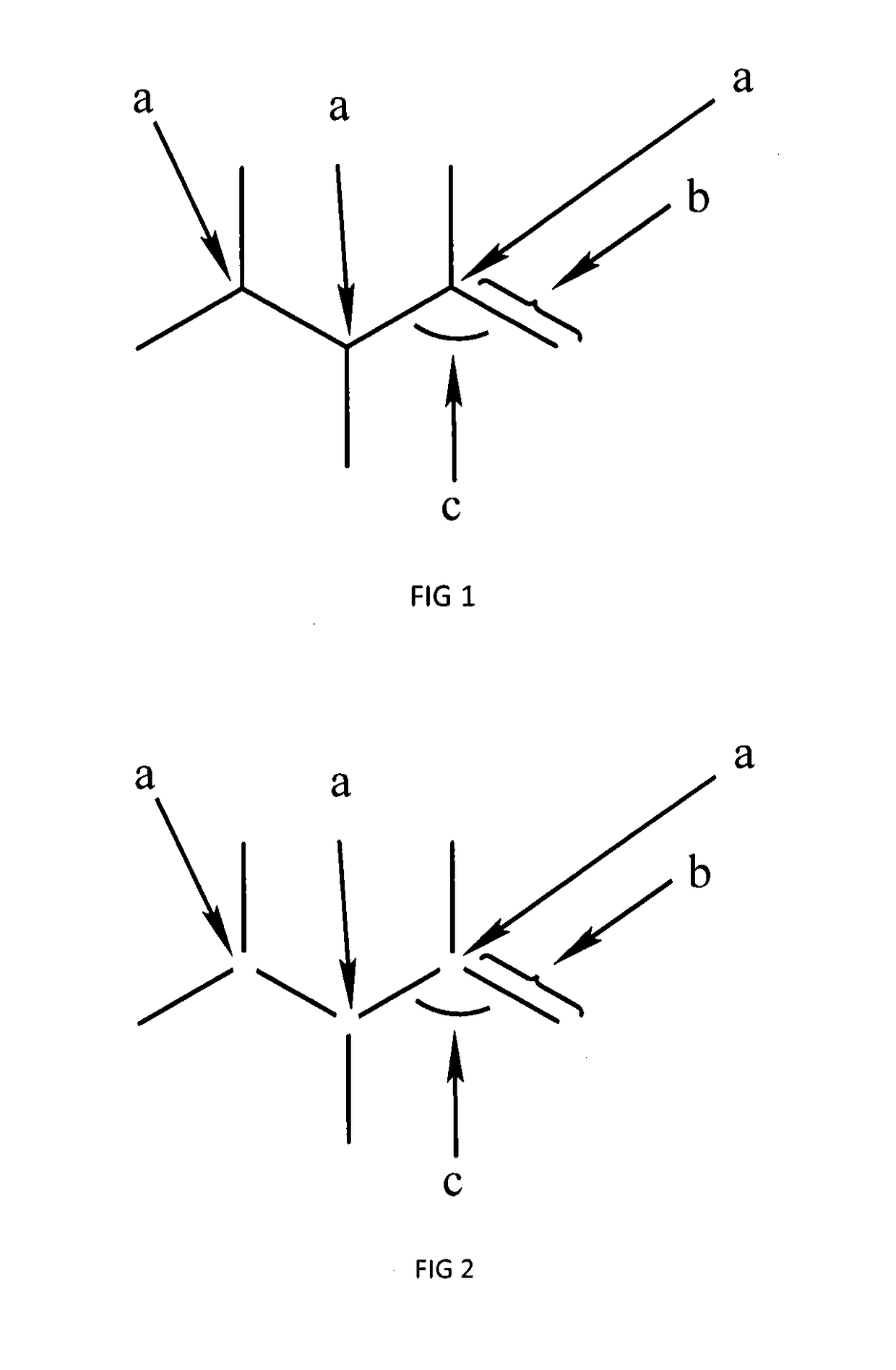

[0061]The invention also provides a method for obtaining the polyamide fiber with improved comfort management as described above. The polyamide fiber is obtained by melt-spinning extrusion. The “melt-spinning extrusion” is understood to mean the extrusion process of converting the polyamide into polyamide fibers. The polyamide(s) may be fed to the melt-spinning device in pellet, powder or melt form. The method includes any conventional extrusion spinning means suitable for melt-spinning extrusion of polyamides, these means being well known by a person skilled in the art, such as single-screw extruder, double-screw extruder, bi-component extruder and grid spinning head. The melt-spinning extrusion can be further defined as being LOY (low-oriented yarn), POY (partially oriented yarn), FDY (fully drawn yarn), FOY (fully oriented yarn), LDI (Low denier Industrial) or HDI (High denier Industrial).

[0062]The melt-spinning extrusion advantageously comprises the following steps:[0063]a1. Fee...

second embodiment

[0086]According to a second embodiment of the present invention, the polyamide fiber obtained from the first embodiment is then texturized to produce textured yarns with higher elasticity, volume and softness. This process comprises any technology known by those skilled in the art such as false-twist texturizing, false-twist-fixed texturizing and air-jet texturizing. Most preferably false-twist texturing.

[0087]The method can include the following steps:[0088]b1. The fiber is removed from the package and passes to the delivery rolls.[0089]b2. The fiber passes through a heater, then to a cold zone.[0090]b3. The fiber passes through a spindle containing rotating discs (friction aggregates)[0091]b4. intermingling points and coning oil are applied to the fiber.[0092]b5. The fiber is wound into bobins.[0093]Wherein a drawing ratio is given to the fiber by altering the speed ratio of the b1 and b5.

[0094]In step b1, the fiber is advantageously placed in a creel and is unwound from the bobbi...

examples

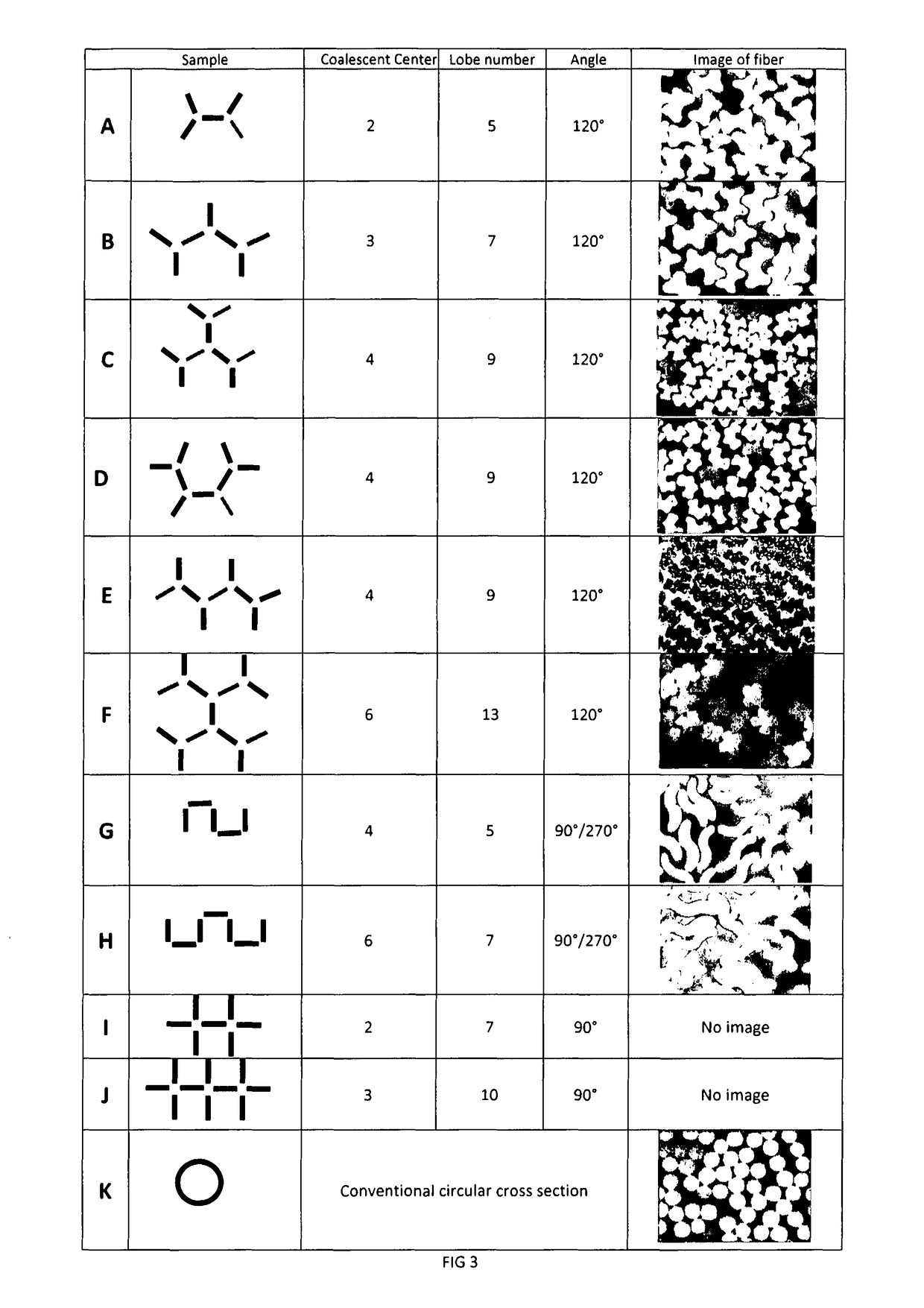

[0117]A series of polyamide articles, including comparative polyamide articles and control polyamide articles are formed and evaluated for process ability, water wicking rate, water absorption rate, water drying rate, hygroscopicity, mechanical properties, IVN (viscosity index), ATG (terminal amino groups) and CTG (carboxylic terminal groups). Table 1 summarizes the samples.

Amino Terminal Group Content (ATG)

[0118]The amino end group (ATG) content was determined by a potentiometric titration method. The quantity of 2 grams of polyamide is added to about 70 ml of phenol 90% wt. The mixture is kept under agitation and temperature of 40° C. until complete dissolution of the polyamide. The solution is then titrated by 0.1N HCl at about 25° C. The result is reported as equivalent / ton (eq / ton). In the case of analyzing fibers and articles, any residue or spin-finish must be previously removed.

Solution Viscosity (IVN)

[0119]The determination of the solution viscosity (IVN) is performed accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com