Method for forming planarized etch mask structures over existing topography

a topography and etching technology, applied in the field of forming planarized etching mask structures over existing topography, can solve the problem of becoming more difficult to maintain the aspect ratios necessary for high fidelity pattern transfer, and achieve the effect of reducing the collapse of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

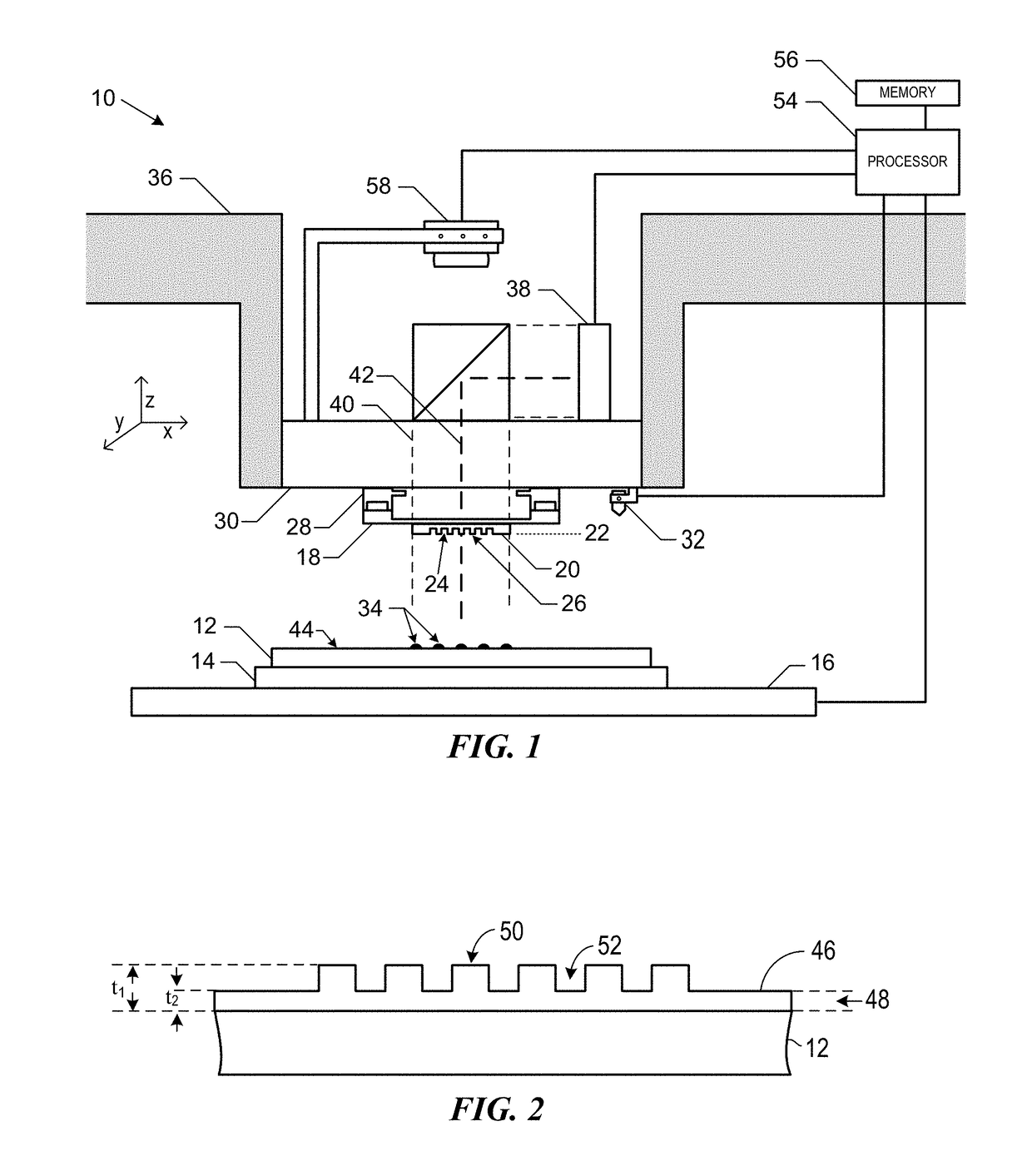

[0035]As previously noted, patterned features can be formed by a number of different lithographic techniques including photolithography, nanoimprint lithography, extreme ultraviolet lithography and electron beam lithography, and the like. The pattern features are used as an etch mask to define a pattern transferred into an underlying material, film or substrate. An exemplary nanoimprint lithography system is illustrated in FIG. 1. Nanoimprint lithography system 10 can be used to form a relief pattern on substrate 12. Substrate 12 may be coupled to substrate chuck 14. As illustrated, substrate chuck 14 is a vacuum chuck. Substrate chuck 14, however, may be any chuck including, but not limited to, vacuum, pin-type, groove-type, electrostatic, electromagnetic, and / or the like. Exemplary chucks are described in U.S. Pat. No. 6,873,087, which is hereby incorporated by reference herein.

[0036]Substrate 12 and substrate chuck 14 may be further supported by stage 16. Stage 16 may provide tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| feature size | aaaaa | aaaaa |

| feature size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com