Valve timing control apparatus for internal combustion engine and internal combustion engine using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

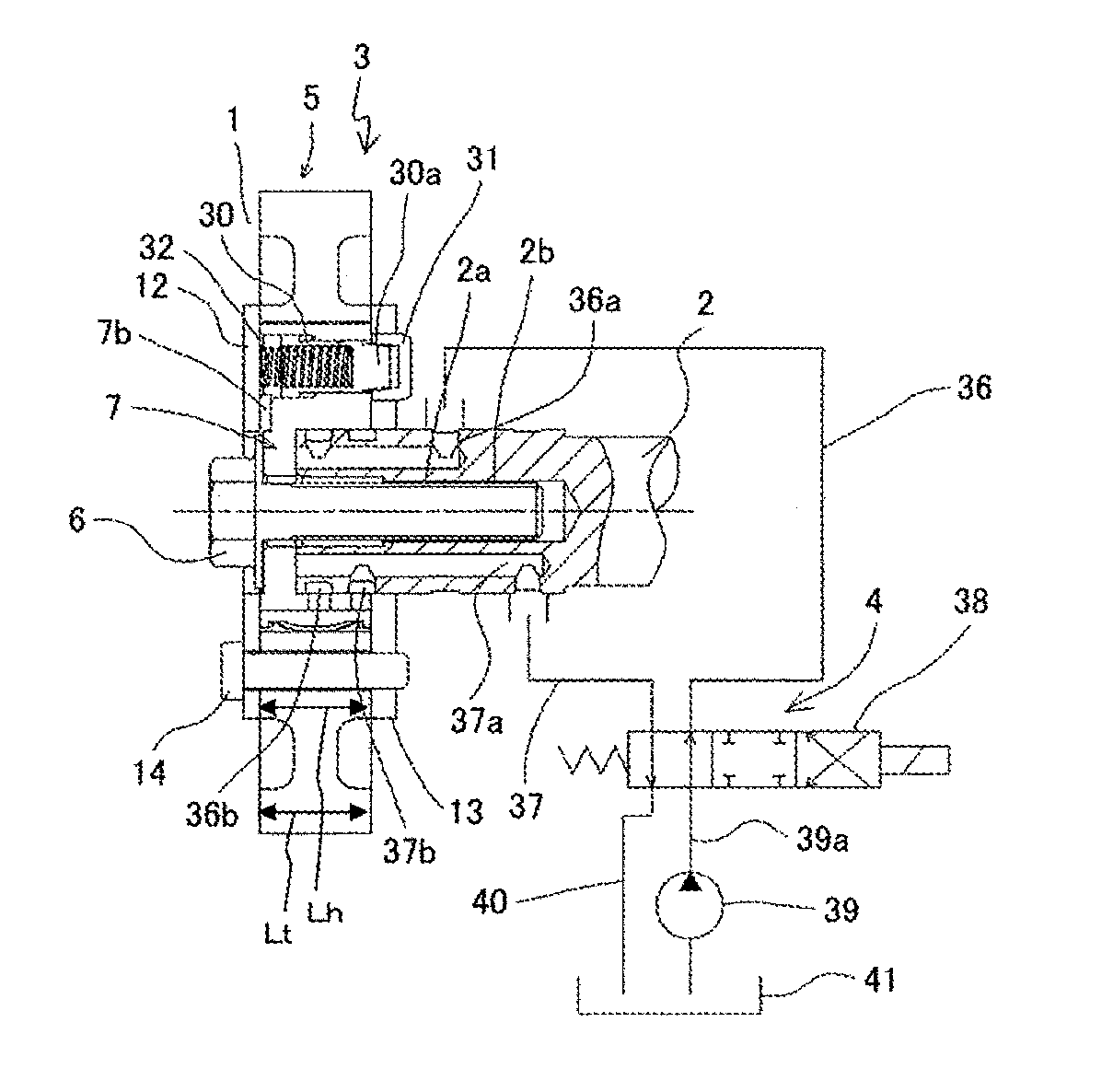

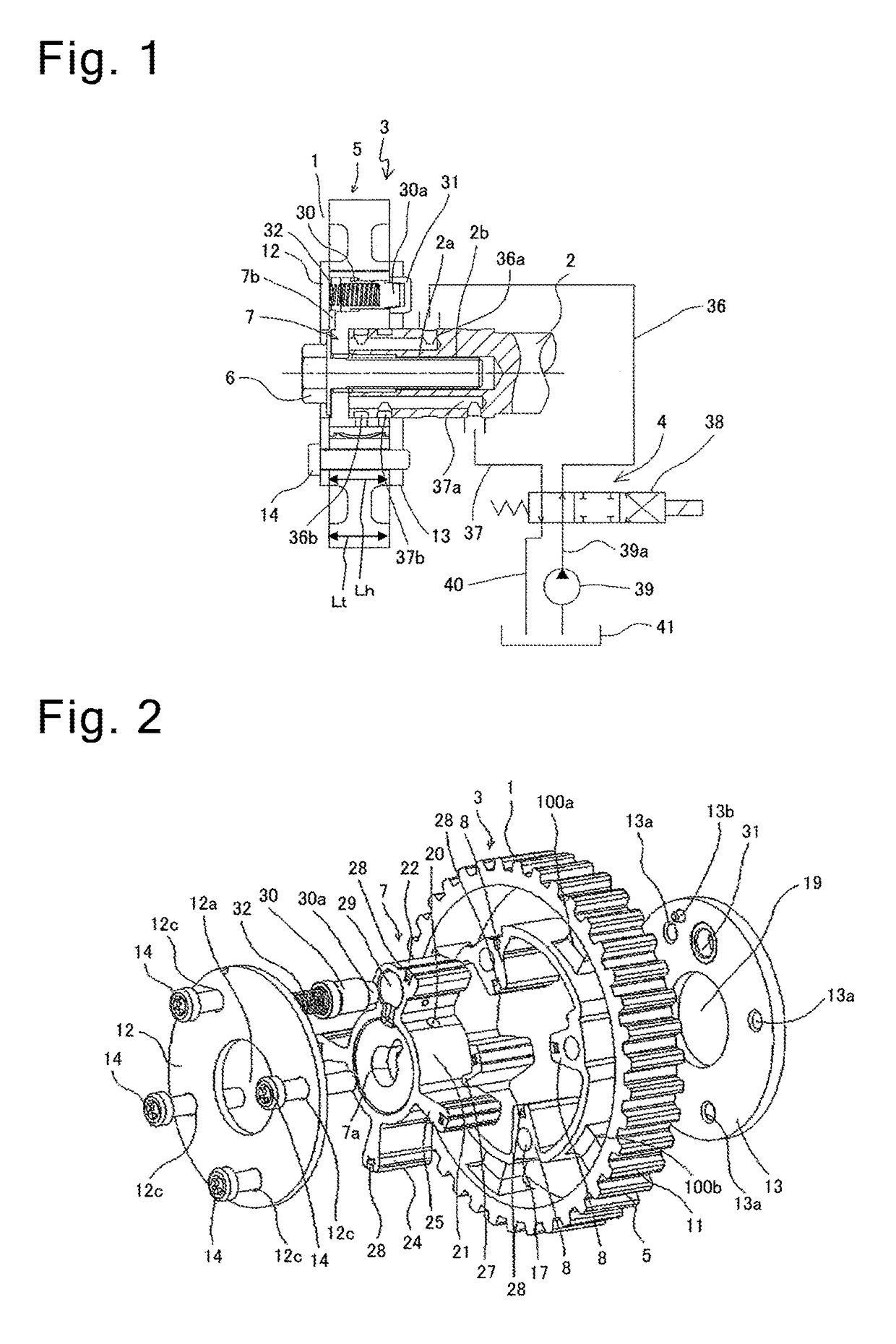

[0020]In the following description, a valve timing control apparatus for an internal combustion engine according to a first embodiment of the present invention will be described in detail with reference to FIGS. 1 to 5.

[0021]The valve timing control apparatus illustrated in FIG. 1 is disposed on an upper surface of a cylinder head of an engine, and functions to control an opening / closing timing of an engine valve. Then, the valve timing control apparatus includes a timing pulley 1, a camshaft 2, a phase conversion mechanism 3, and a hydraulic circuit mechanism 4. The timing pulley 1 is rotationally driven by a crankshaft rotatable according to activation of a not-illustrated piston of the engine via a timing belt. The camshaft 2 is provided rotatably relative to the timing pulley 1. The phase conversion mechanism 3 is disposed between the timing pulley 1 and the camshaft 2, and converts a relative rotational position between them. The hydraulic circuit mechanism 4 supplies hydraulic...

second embodiment

[0067]Next, a valve timing control apparatus according to a second embodiment of the present invention will be described with reference to FIGS. 6 and 7. The present embodiment is basically similar to the first embodiment, and therefore similar functions and effects to the first embodiment will not be described below.

[0068]FIG. 6 illustrates a maximum retard angle state, and FIG. 7 illustrates a maximum advance angle state. A retard angle-side stopper surface 200a and an advance angle-side stopper surface 200b are formed on both side surfaces of the vane 22 having the maximum width. Then, a retard angle-side abutment surface 300a is formed on a wall surface of a shoe 8r which the retard angle-side stopper surface 200a hits and abuts against, and an advance angle-side abutment surface 300b is formed on a wall surface of a shoe 8a which the advance angle-side stopper surface 200b hits and abuts against.

[0069]Then, when the valve member 7 is controlled to the maximum retard angle posit...

third embodiment

[0075]Next, a valve timing control apparatus according to a third embodiment of the present invention will be described with reference to FIG. 8. The present embodiment is basically similar to the first embodiment, and therefore similar functions and effects to the first embodiment will not be described below.

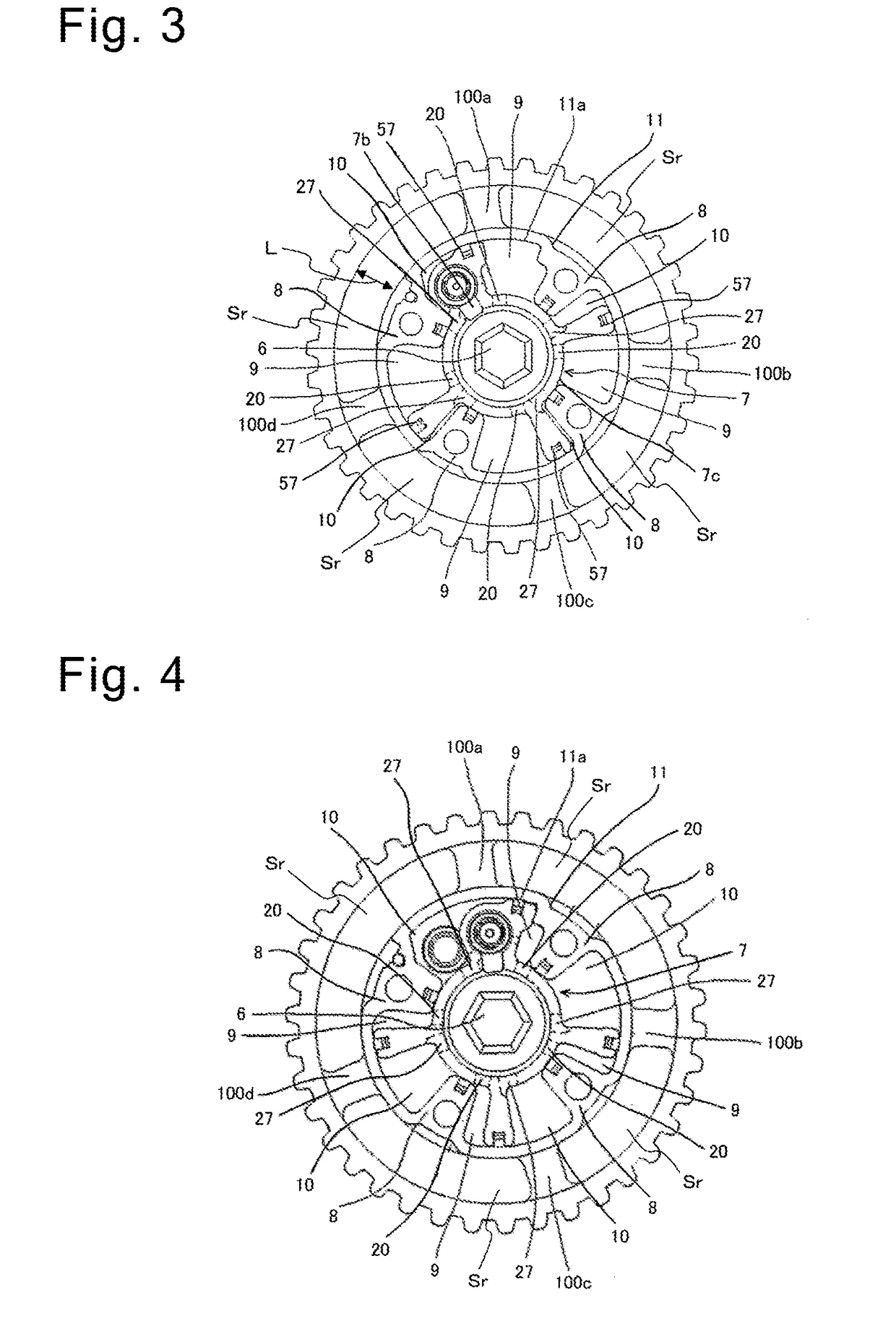

[0076]In the present embodiment, the coupling beam portions 100a to 100d are disposed at positions where the individual shoes 8 formed on the housing main body 11 and the timing pulley 1 face each other as illustrated in FIG. 8. In other words, the coupling beam portions 100a to 100d are provided while being arranged on outer sides in the radial directions of the individual shoes 8 as indicated by an arrow A. Such a configuration is employed for the following reason.

[0077]The bolt 14 is inserted through the bolt insertion hole 17 of each of the shoes 8, and the front plate 12, the housing main body 11, and the rear plate 13 are securely fastened. Therefore, side clearances betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com