Sportsboard Stiffening System

a technology of stiffening system and surfboard, which is applied in the field of sportsboards, can solve the problems of board breaking problems, limited vertical height of wood stringers, and high cost, and achieve the effects of enhancing safety for surfboard riders, reducing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

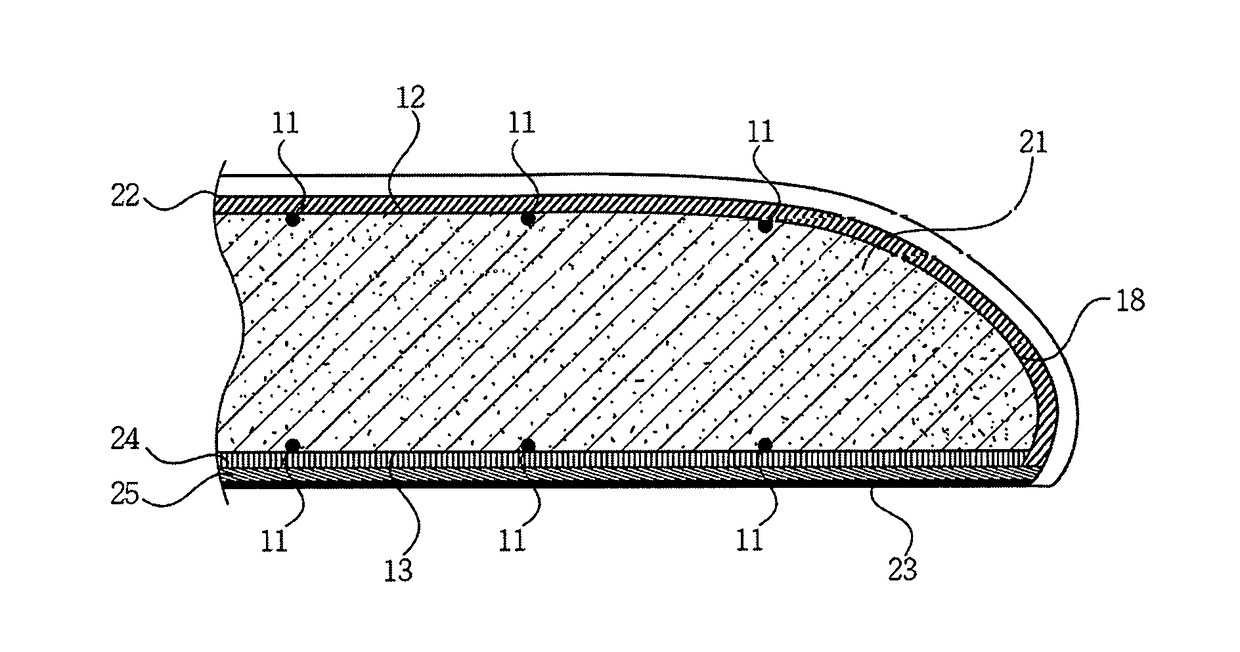

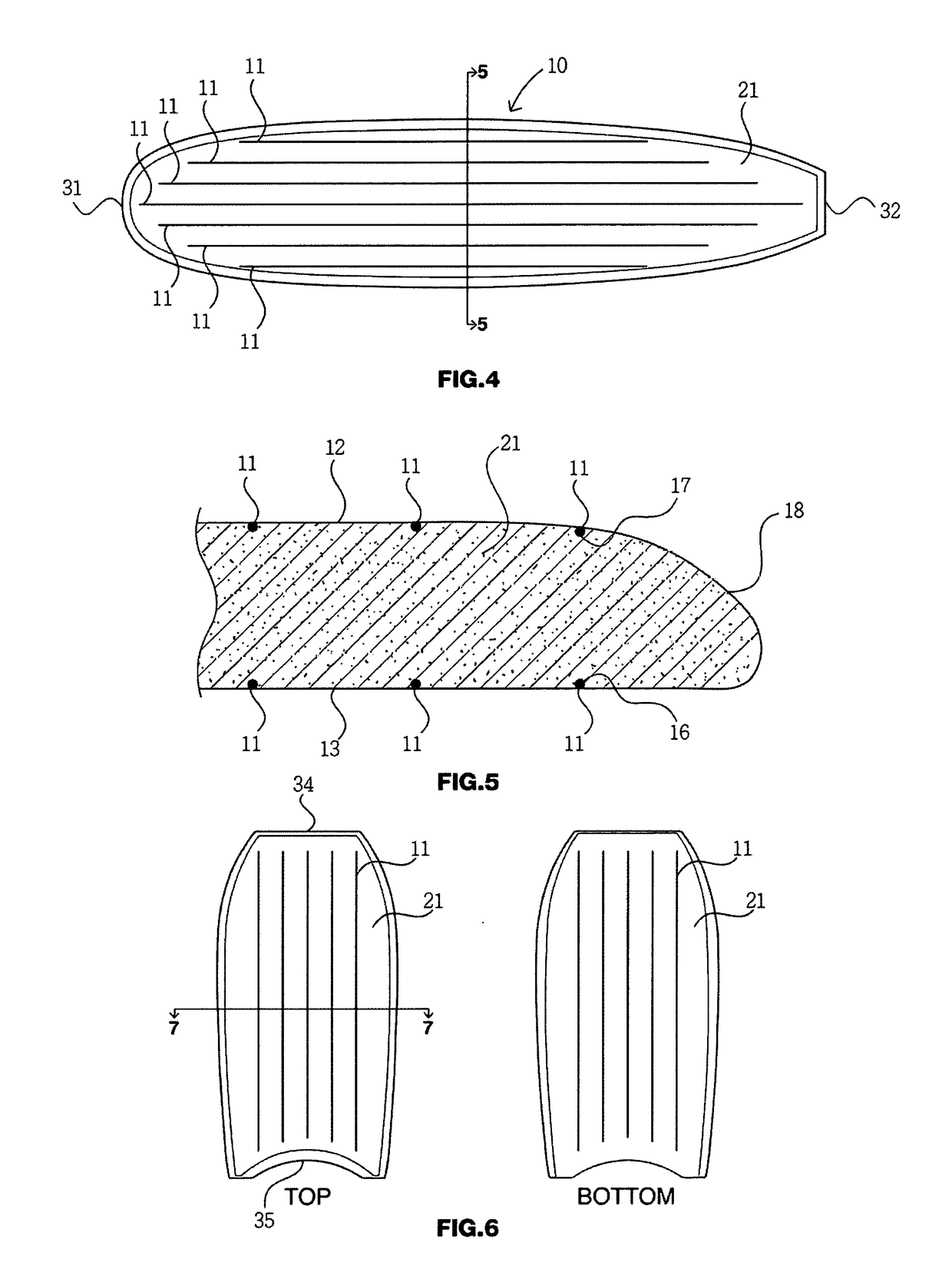

[0082]In the preferred first embodiment shown in FIGS. 4 and 5, the stiffening system 10 comprises fibrous profiles 11 adhered on both the foam core top surface 12 and the foam core bottom surface 13 of the surfboard foam core 21. A foam core groove 16 formed on the surface of the foam core 21 can receive the fibrous profiles 11. The foam core groove 16 is preferably deep enough to allow the fibrous profile 11 to be encapsulated within the foam core. A typical foam core suitable for the present invention is made of expanded polystyrene foam (EPS). In the preferred embodiment, the fibrous profiles are completely or partially embedded inside the foam core such as in foam core grooves 16. The grooves can be cut as slots with a blade to create an incision. The foam core grooves 16 can receive a fibrous profile adhesive coating 17 such as a glue. In an alternative embodiment, the fibrous profiles may be bonded to the surface of the foam core. In another embodiment, a backing layer may be...

third embodiment

[0083]In an alternative embodiment, the fibrous profiles may be adhered only on the top surface of the foam core. In another alternative third embodiment, the fibrous profiles may be adhered only on the bottom surface of the foam core. Various modifications can be made without departing from the spirit and scope of the invention. For example, the fibrous profiles may be adhered on any desirable position of the stringer body and additional number of fibrous profiles may be applied to the foam core according to the requirement of mechanical properties. For example, the foam core upper rail surface 28 and the foam core lower rail surface 29 can receive fibrous profiles as well.

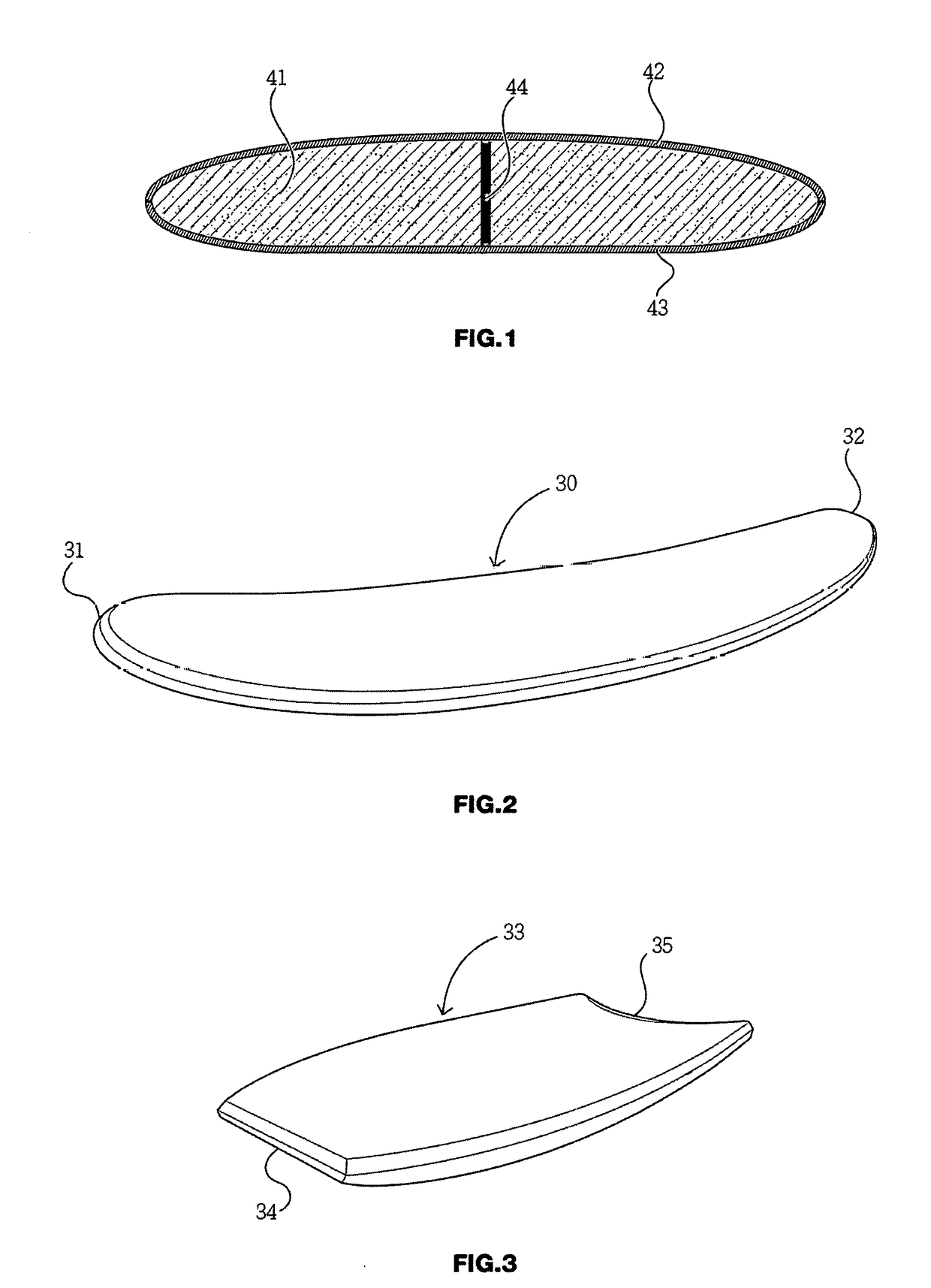

[0084]The fibrous profile has a cross-section of round shape, rectangle, parallelogram, triangle or any other profile shape, more preferable a round cross-section. As illustrated in FIG. 2, a typical surfboard 30 has an upturning front end 31 and an upturning tail end 32, which are commonly called the nose rocker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com