Densified foam core (DFC) board for use as a backing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

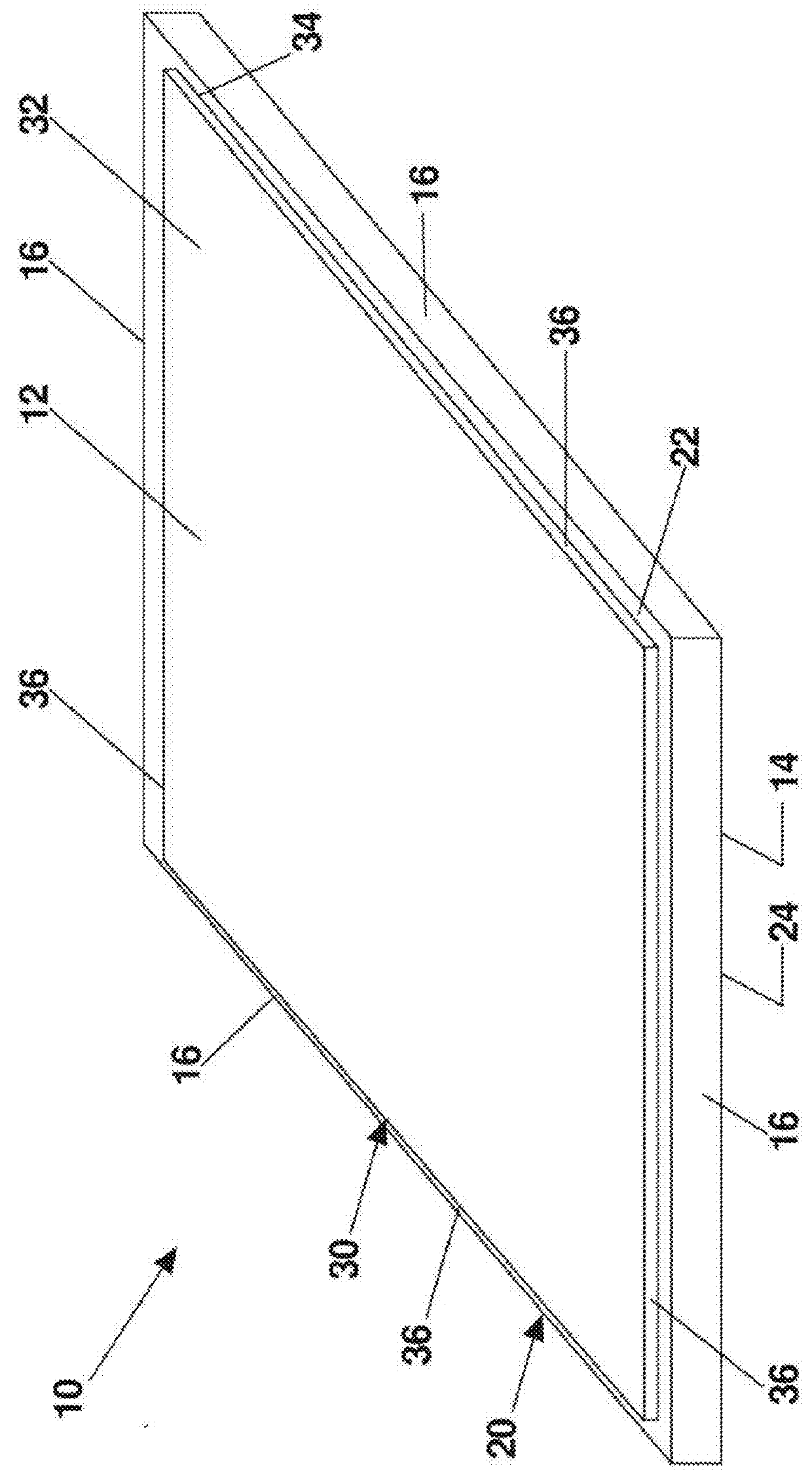

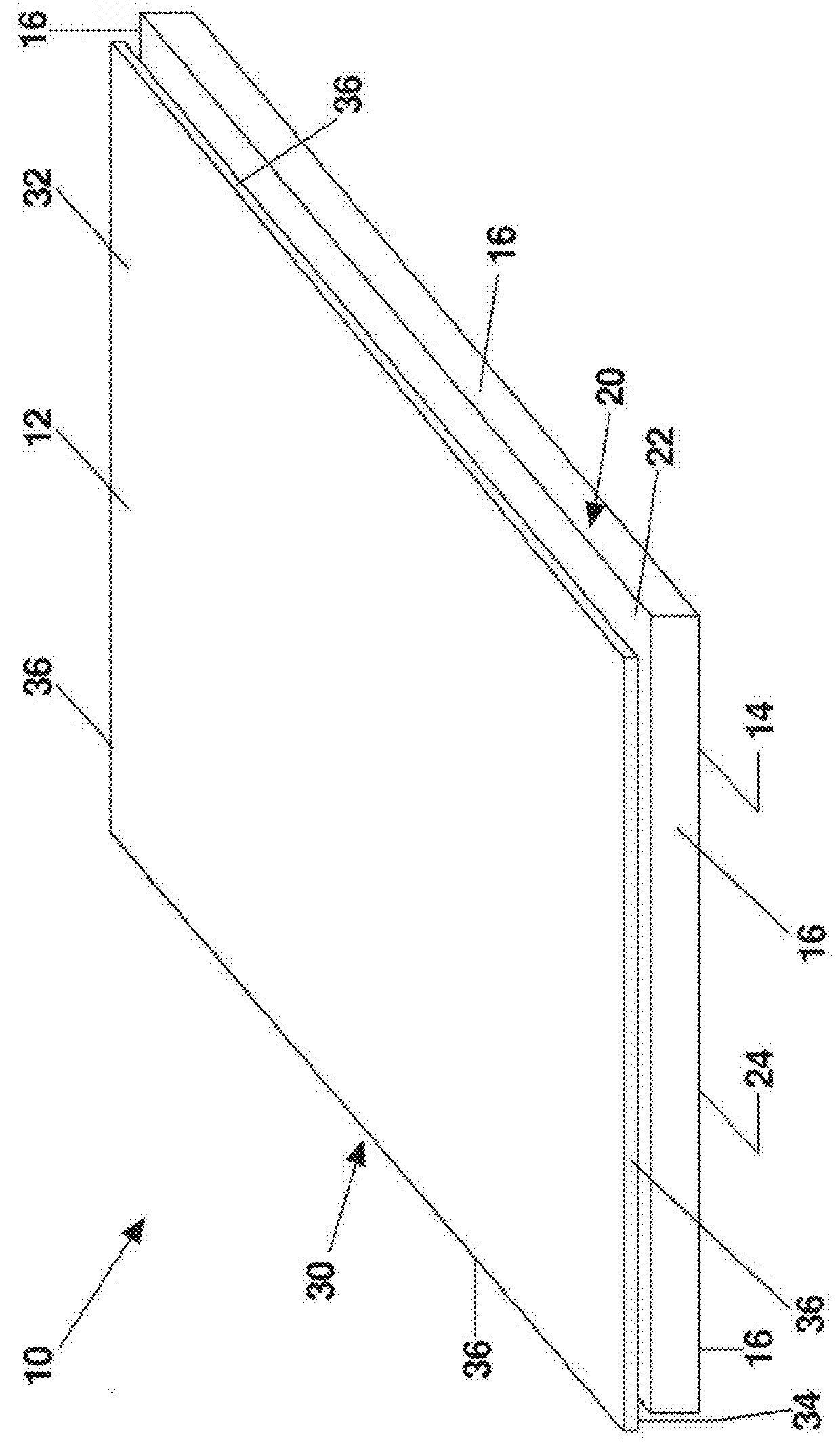

[0022]The present invention is directed towards a panel or board, generally indicated as 10, that may be used as backing support for a variety of different applications. While the present invention is referred to herein primarily as a board or panel, it may also comprise a sheet or other similar structure, and consequently, this terminology should not be deemed a limiting factor.

[0023]As will be explained in greater detail below, the board 10 of the present invention is intended for installation on an unfinished floor, wall, soffit, ceiling, or other similar surface. By way of example, the board 10 may be secured to an unfinished wall such as a masonry wall or a concrete wall, or against an unfinished floor such as a concrete slab or floor. In most instances, the board 10 will typically be nailed, screwed or drilled into place, but may also be secured by other methods. Also, the board 10 of the present invention is well suited to level an otherwise uneven surface, but it may also be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com