Fill packaging method and fill packaging machine for liquid packing material

a liquid packing material and packaging machine technology, applied in the directions of transportation and packaging, packaging, transit packaging, etc., can solve the problems of insufficient suppression of packing material intrusion poor sealing, and inability to push out granulates by the heat sealing bars, so as to improve productivity, suppress the effect of biting into the lateral sealing portion and more effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]An embodiment of the invention will be described with reference to the accompanying drawings below.

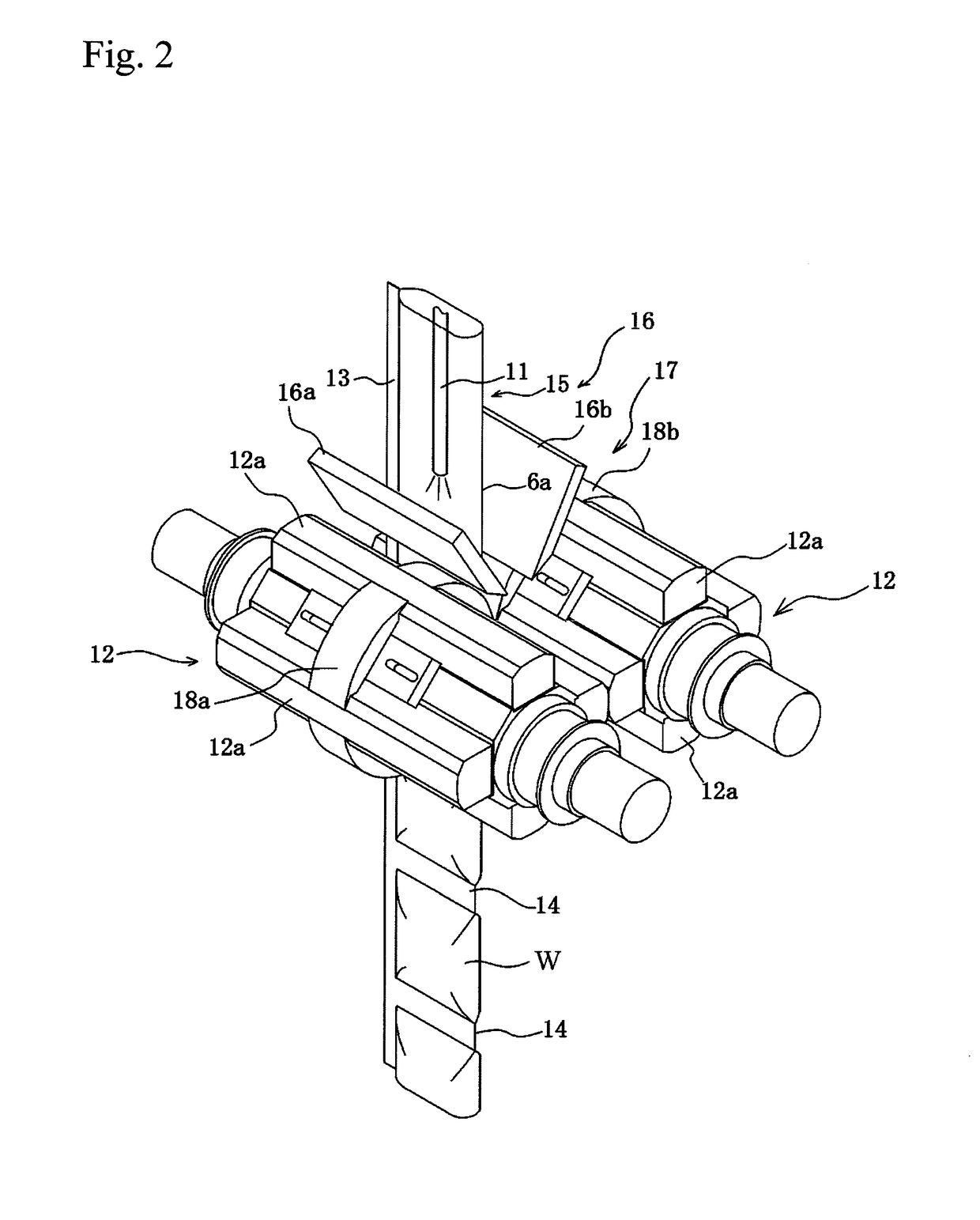

[0039]FIG. 1 is a schematic view illustrating a construction of a vertical fill packaging machine as an example of the fill packaging machine according to the invention.

[0040]In the vertical fill packaging machine, an elongated packaging film made of a laminate film by laminating a base film layer made, for example, from a biaxially oriented ethylene-vinyl alcohol copolymer resin or the like and a sealant layer made, for example, from a non-oriented ethylene-vinyl acetate copolymer resin or the like is folded in a widthwise direction so as to face the sealant layers to each other to overlap both side edge parts with each other while being run in its longitudinal direction, and many package bags are made from the packaging film and a packing material such as food and drink, seasonings, medicines, cosmetics and other liquidus, viscous or jelly fluidizing material is automatically f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com