Machine and method for the automatic preparation of substances for intravenous application

a technology of automatic preparation and intravenous application, which is applied in the direction of packaging, pharmaceutical product form change, liquid material, etc., can solve the problems of insufficient and unsatisfactory capacity/preparation speed, low productivity, and no machine known in the prior art for preparing mixtures for intravenous application allows the preparation of paediatric medicines, etc., to achieve improved capacity and preparation speed, improve the speed of substance preparation, and improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

of the Preparation Zone

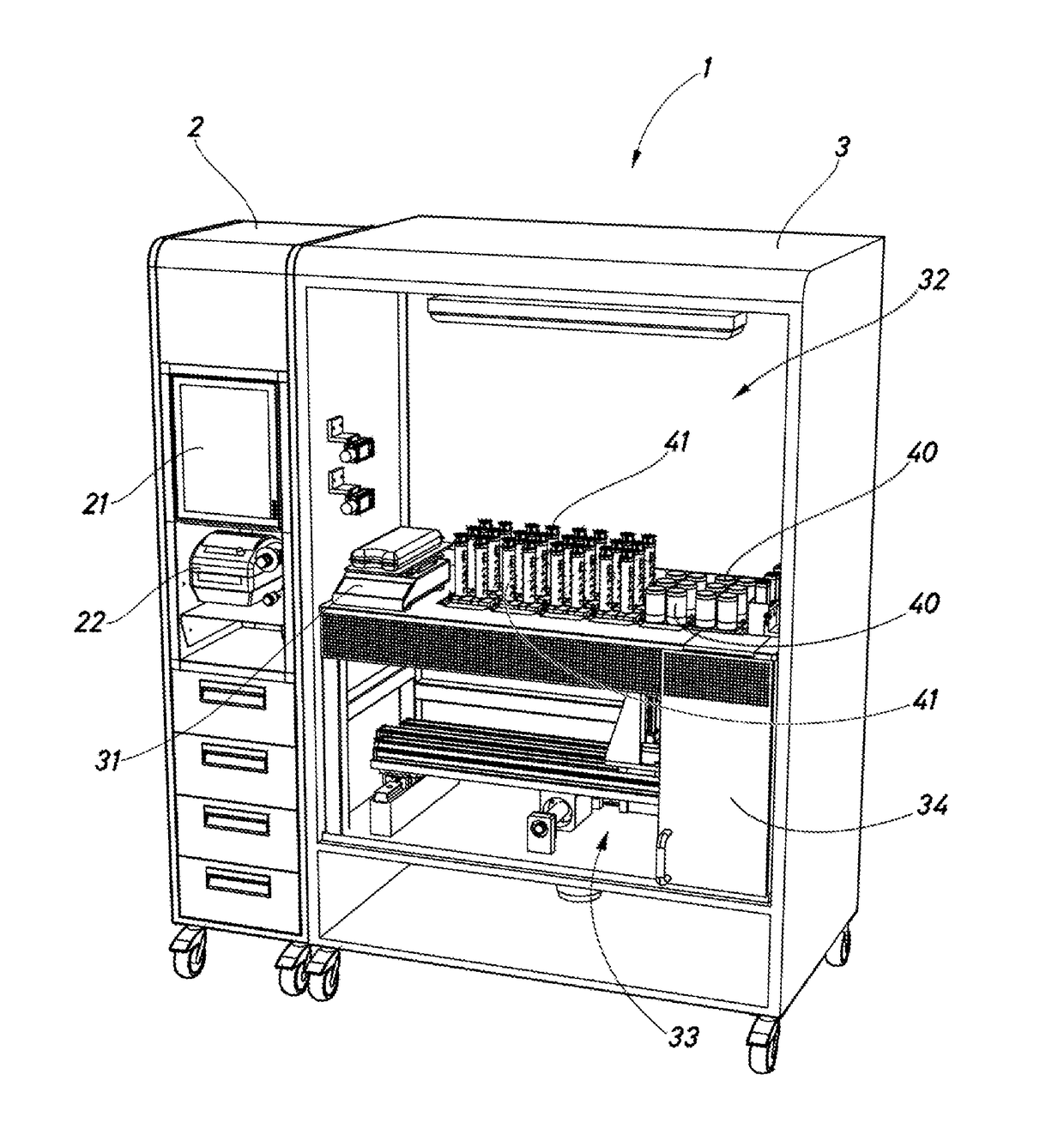

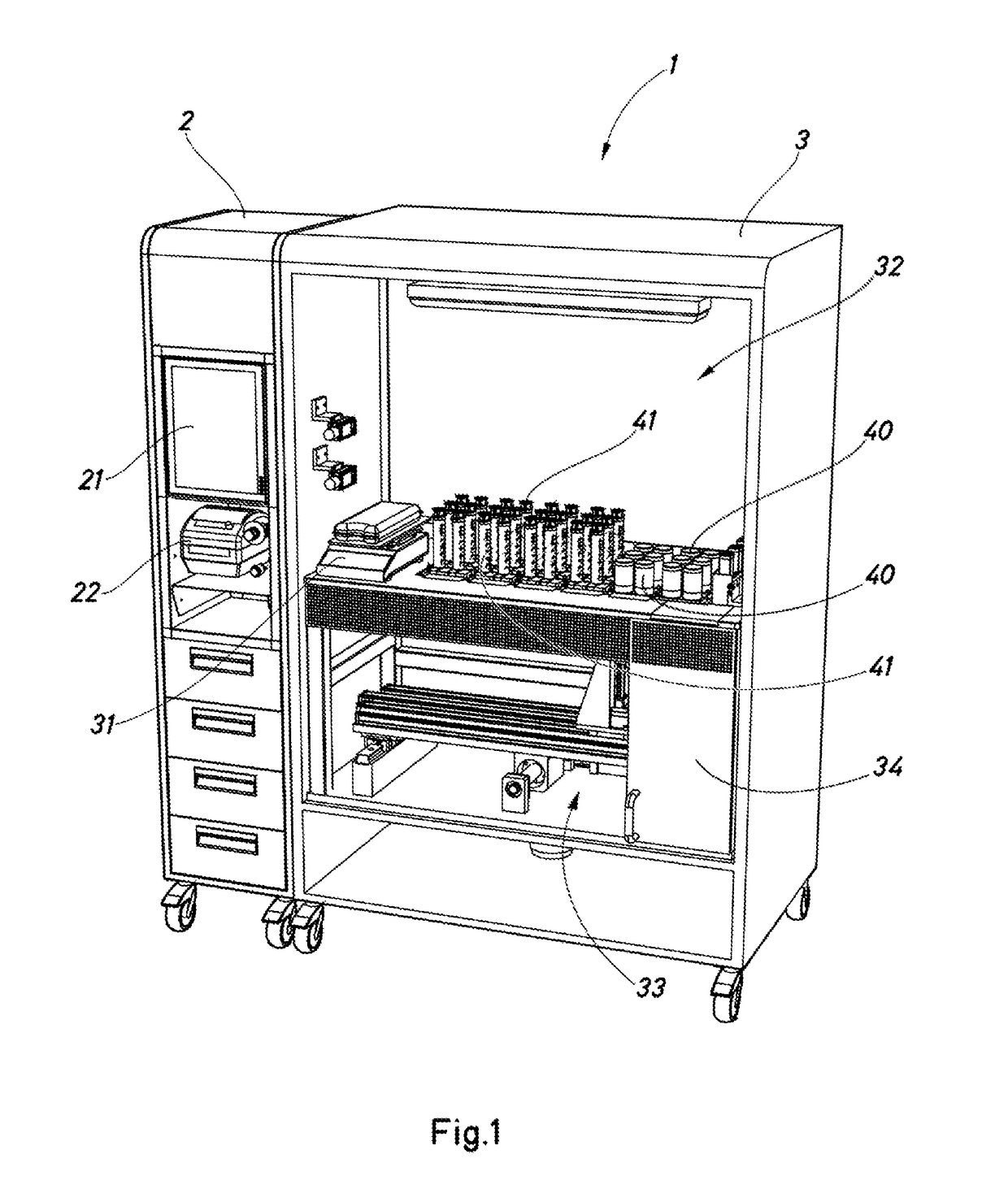

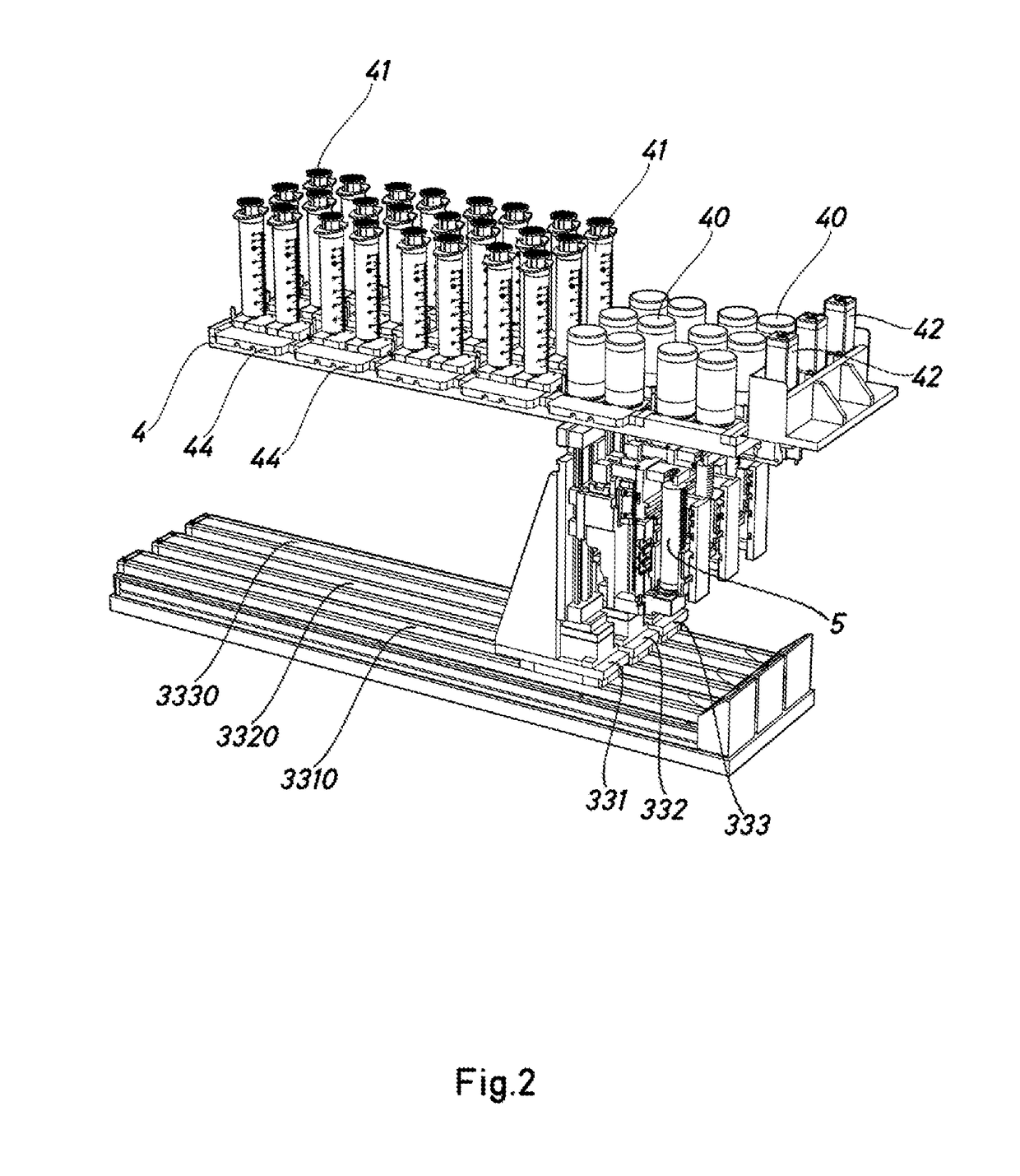

[0054]FIG. 2 shows a first embodiment of the preparation zone of the machine according to the present invention. Some elements and / or devices of the machine -1- have been omitted in order to more clearly show the arrangement of the different containers on the tray -4- as well as the arrangement and interaction of the actuators of the different substance metering lines. In this embodiment, as will be explained in more detail below, the metering is carried out using syringes -5- having a piercing point or needle operated by each actuator (-331-, -332-, -333-) of each metering line, respectively. As indicated above, the terms needle or piercing point shall be understood as the tube that is typically made of metal and of small diameter, of which the free distal end is bevel-cut and the other end of which is provided with a bushing that is connected to the distal portion of the barrel of the syringe for the injection, insertion or removal of substances.

[0055]Accord...

second embodiment

of the Preparation Zone

[0074]FIG. 8 shows a second embodiment of the preparation zone of the machine -1- according to the present invention, and in particular a second embodiment of a syringe actuator -6- according to the present invention. Some elements and / or devices have been omitted from the machine -1- to more clearly show the structure of the actuator -6- arranged in a substance metering line along a horizontal guide -60-.

[0075]In this second embodiment, as will be explained in more detail below, metering takes place using syringes -7- having no piercing point, operated by a respective actuator -6- along a horizontal guide -60-. The barrel -71- of each syringe -7- comprises a female-female “Luer-Lock” adaptor -710- arranged on its respective inlet / outlet nozzle, as shown in FIG. 9, for direct connection to / disconnection from the male “Luer-Lock” nozzles of the initial and final containers. In addition, according to this second embodiment, the initial containers may be flasks, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width×height×depth | aaaaa | aaaaa |

| width×height×depth | aaaaa | aaaaa |

| volumes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com