Cooling Apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

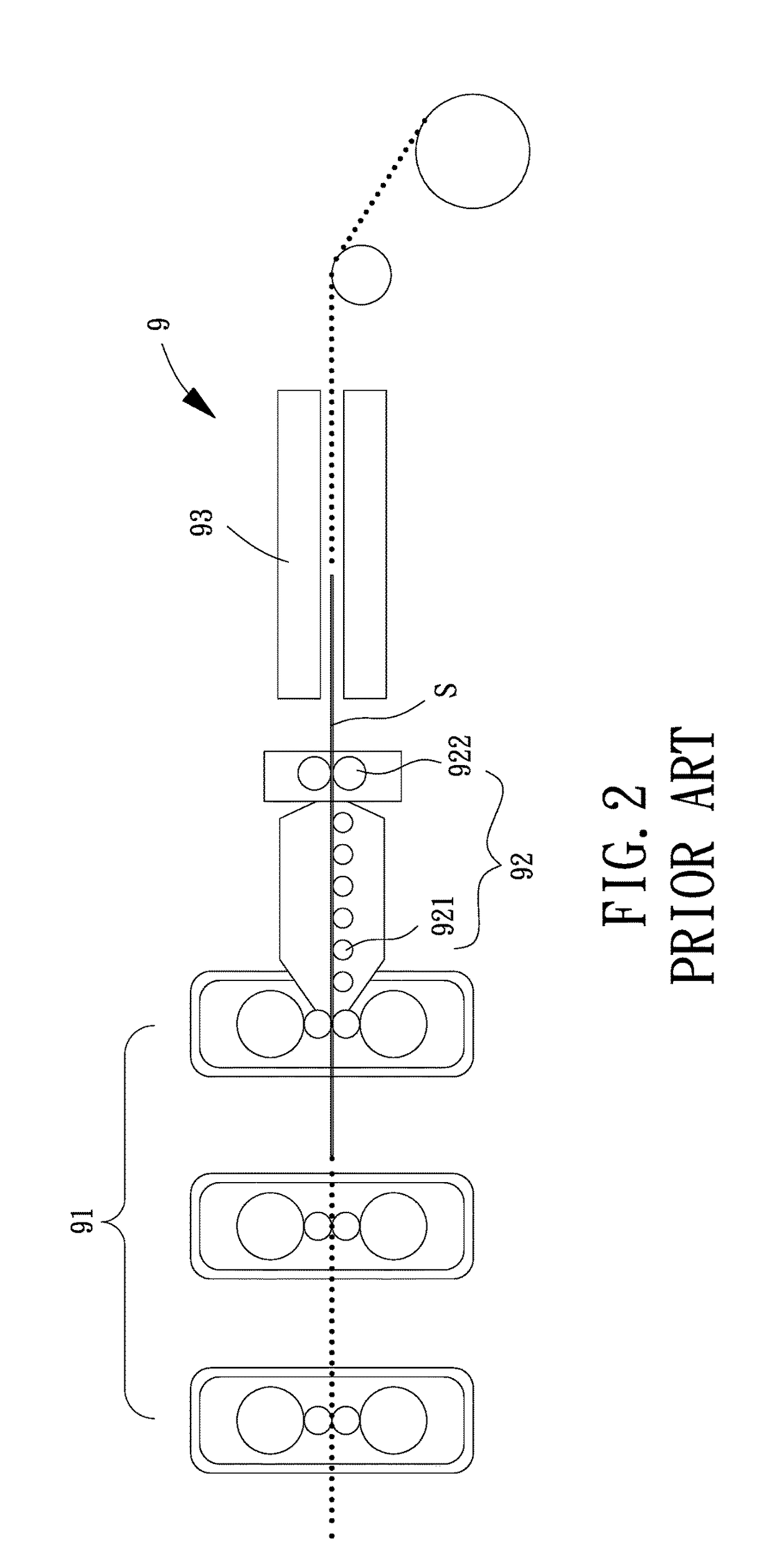

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]FIGS. 3 and 4 show a cooling apparatus according to an embodiment of the disclosure. The cooling apparatus includes a convoying unit 1 and a spraying unit 2. The spraying unit 2 is arranged at one side of the convoying unit 1.

[0039]Referring to FIGS. 3-5, the convoying unit 1 includes a base 11 and a plurality of rollers 12. The base 11 includes a feeding end 111 and a discharging end 112 in which a convoying direction D1 extends from the feeding end 111 to the discharging end 112. The rollers 12 are arranged on the base 11. Each of the rollers 12 includes a convoying portion 121. The convoying portion 121 has a diameter which reduces from two ends to the center thereof.

[0040]Referring to FIG. 6, the convoying portion 121 of the roller 12 has a varying diameter in this embodiment. The convoying portion 121 has an outer face which forms a curved face in a linear manner. In the embodiment, the outer face of the convoying portion 121 is in the form of a concave curved face. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com