Combination multi-effect distillation and multi-stage flash evaporation system

a multi-effect distillation and flash evaporation technology, applied in the field of desalination, can solve the problems of increasing turbulent flow, limiting the design capacity of the unit and the maximum permissible operating temperature, and evaporators are susceptible to fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

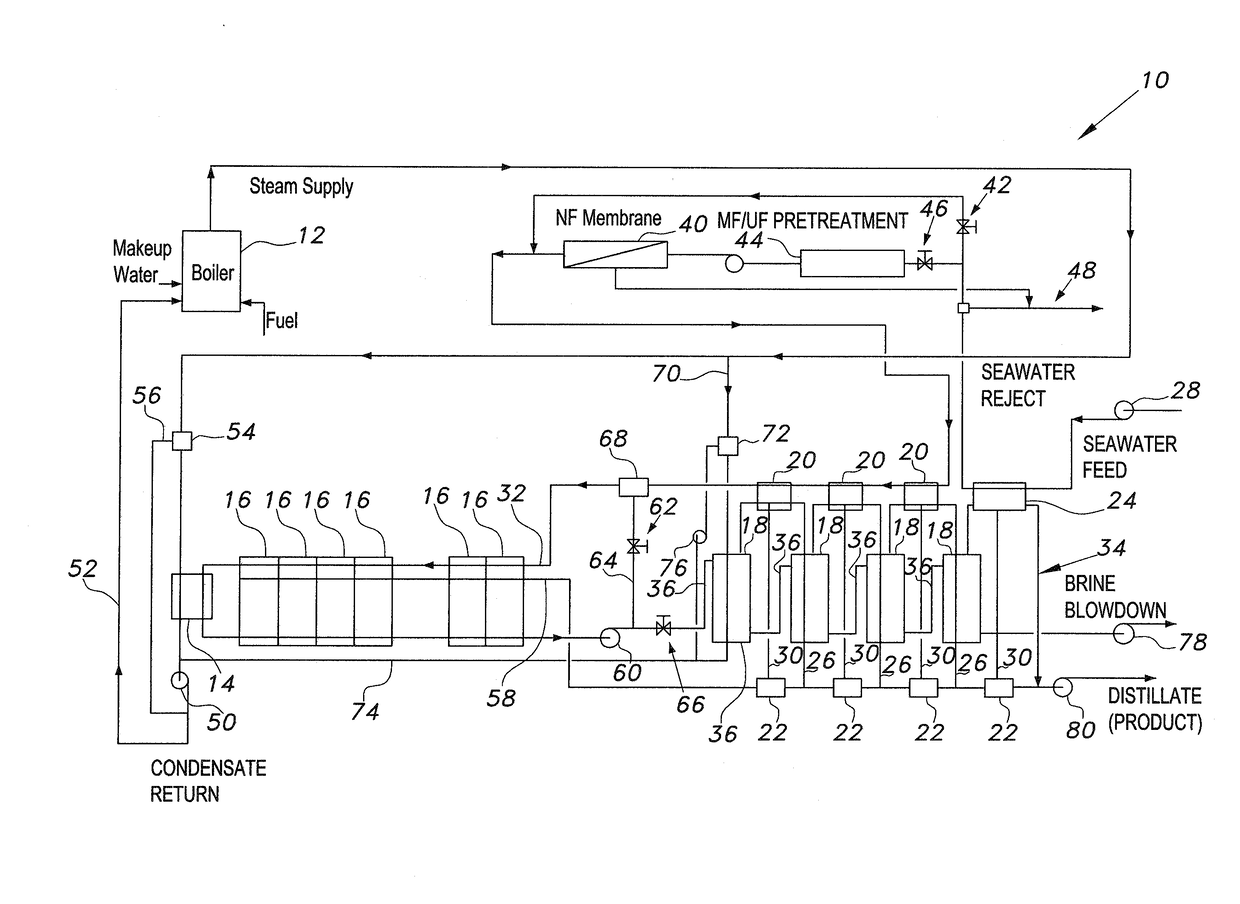

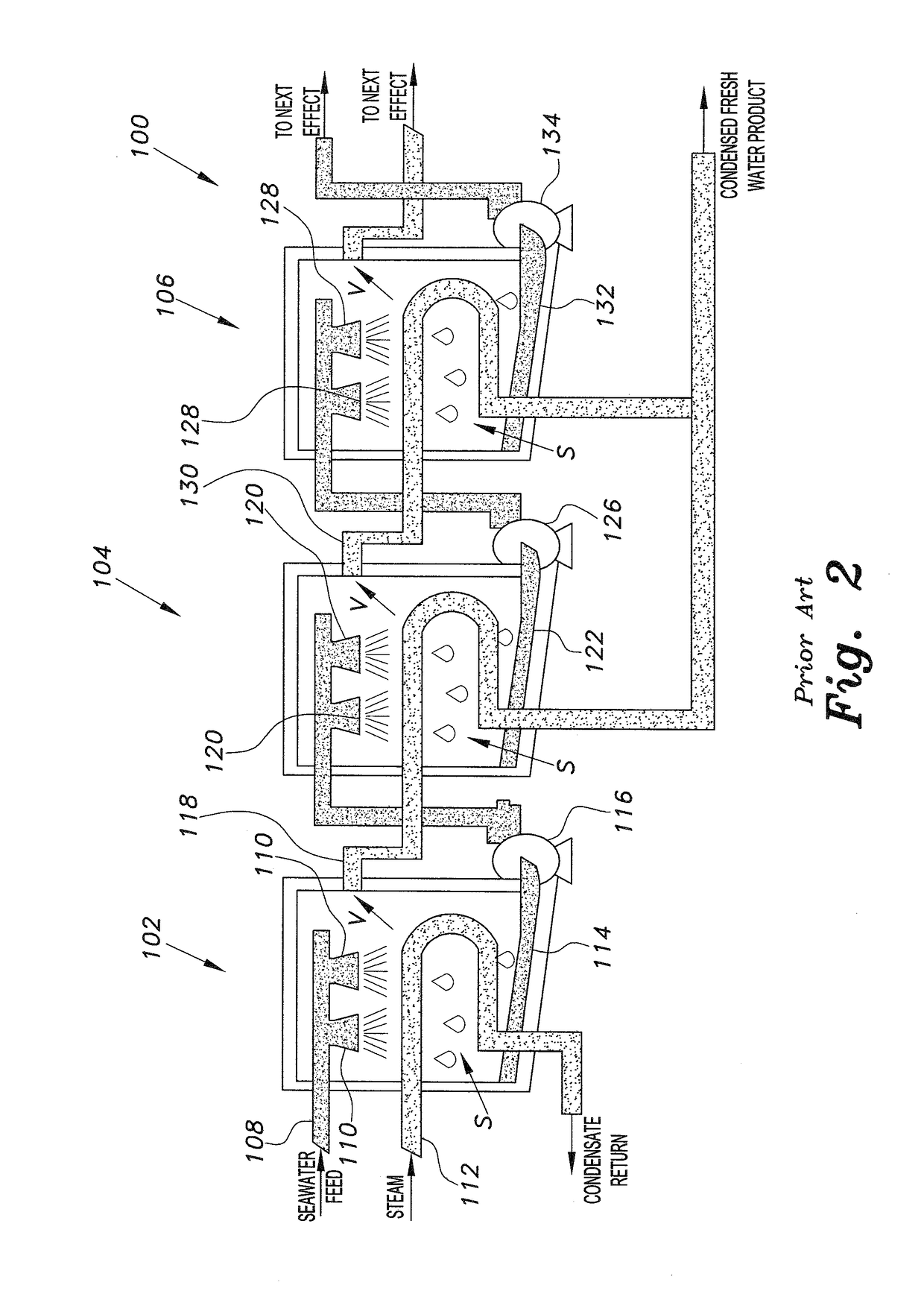

[0041]The combination multi-effect distillation and multi-stage flash evaporation system 10, as shown in FIG. 1, combines a multi-effect distillation (MED) system, similar to the MED system 100 of FIG. 2, with a multi-stage flash (MSF) evaporation system, similar to the MSF evaporation system 200 of FIG. 3. The multi-stage flash evaporation portion of system 10, shown in FIG. 1, begins with a mixture of seawater feed and recycled concentrated brine entering the system under pressure, being drawn into conduits or pipes 32 via a mixer 68 or the like. The seawater feed is drawn from an outside source by a pump 28 and passes through the final condenser 24 of the multi-effect distillation portion of system 10, as will be described in detail below. Prior to injection into the MSF process, the total volume (or, alternatively, only a first portion) of seawater feed is preferably pre-treated by passage through a filtering system 40 using a nanofiltration (NF) membrane or the like. Selective ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com