High-temperature-resistant scale inhibition dispersing agent and preparation method thereof

A scale-inhibiting dispersant, high-temperature-resistant technology, applied in chemical instruments and methods, scale removal and water softening, water/sludge/sewage treatment, etc., can solve time-consuming and labor-intensive equipment, system failure to operate normally, and poor scale-inhibiting ability and other issues, to achieve the effect of promoting the development process, excellent scale inhibition and dispersibility, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

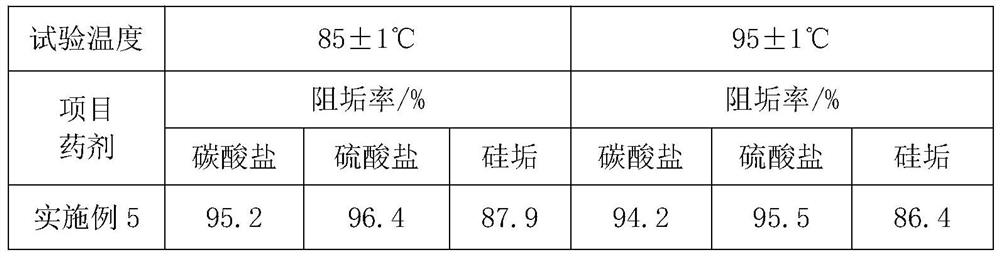

Examples

Embodiment 1

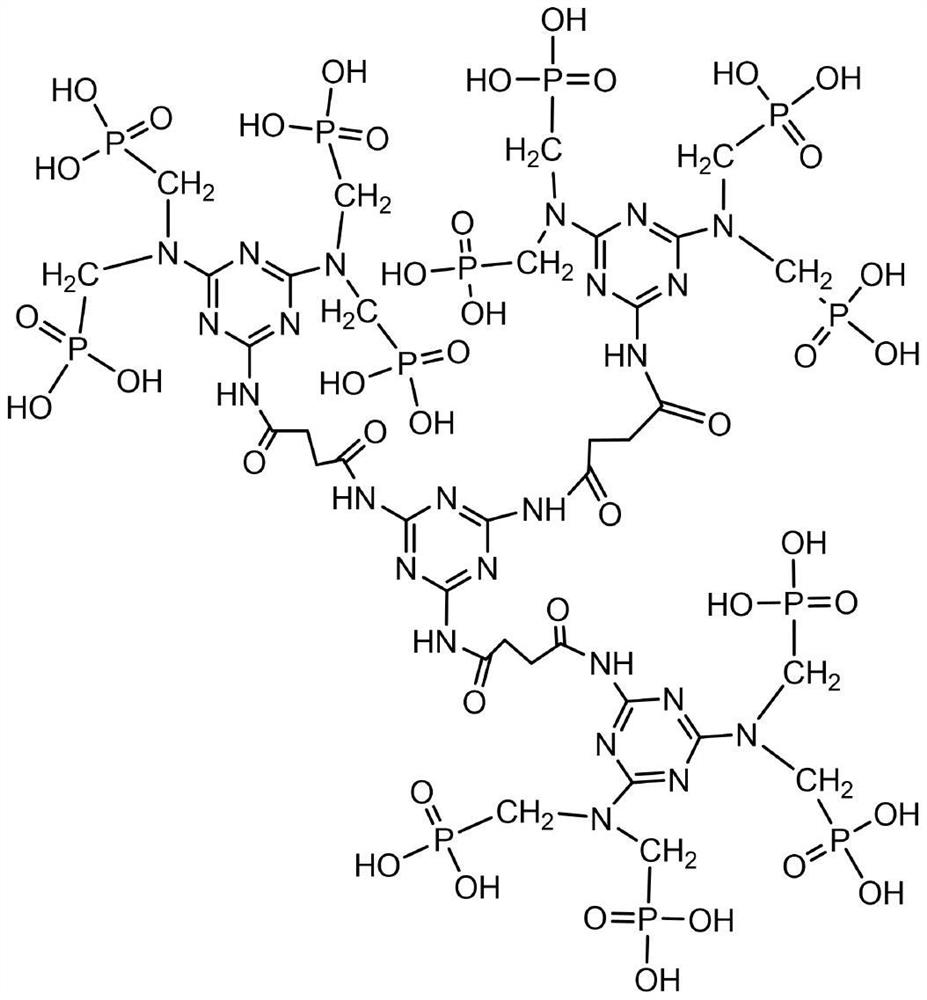

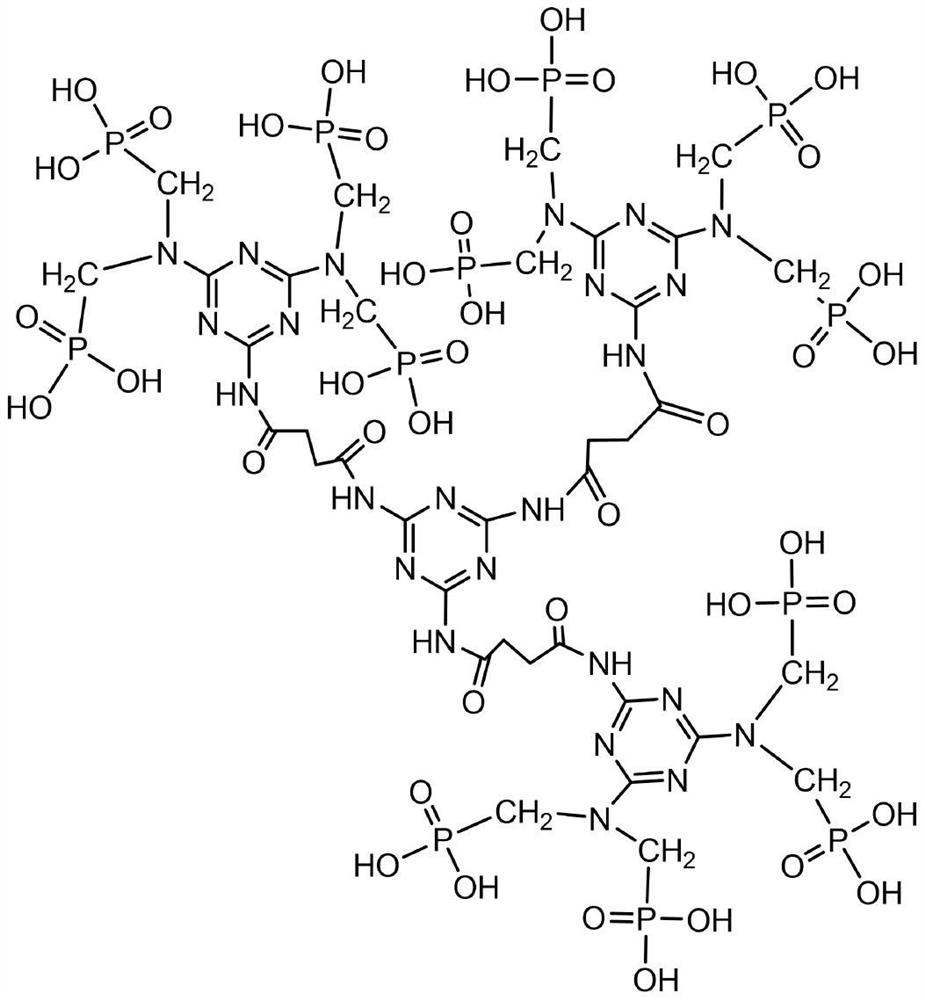

[0038] Preparation of Organophosphine Hyperbranched Macromolecules

[0039] In the reaction kettle, add 1000ml deionized water, heat up to 80-90°C, add 1mol melamine to slowly dissolve, then add 3.5mol succinic anhydride at 110-120°C for 1.5h reaction, then add 3mol melamine, and react at 130°C for 1.5h , lower the temperature to below 60°C, add 20mol 37wt% formalin and 25mol hydrochloric acid, mix well, add dropwise a solution containing 20mol phosphorous acid in the mixture, the dropping temperature is lower than 60°C, after the dropwise addition, 105°C Reflux for 2 hours to obtain organic phosphine hyperbranched macromolecules.

Embodiment 2

[0041] Preparation of multiple copolymers

[0042] S1: Add 10 parts by weight of sodium 2-acrylamide-2-methylpropanesulfonate and 15 parts by weight of deionized water into the reactor, and stir to dissolve;

[0043] S2: Dissolve 5 parts by weight of sodium 2-acrylamide-2-methylpropanesulfonate in 10 parts by weight of deionized water, and add it to the head tank 1;

[0044] S3: Add 20 parts by weight of hydrogen peroxide (27.5% content) into the head tank 2;

[0045] S4: Add 5 parts by weight of L-aspartic acid, 20 parts by weight of succinic anhydride, and 0.005 parts by weight of vanadium pentoxide to the reaction kettle, stir and mix evenly, heat up to 110-115°C and reflux for 1.5h, then cool down to 105°C -110°C;

[0046] S5: slowly drop the sulfonate solution in the head tank 1 and the initiator in the head tank 2 into the reactor, and continue to react for 1.5 hours after the drop addition is completed to obtain the multi-component copolymer A1.

Embodiment 3

[0048] Preparation of multiple copolymers

[0049] S1: Add 10 parts by weight of sodium 2-acrylamide-2-methylpropanesulfonate, 5 parts by weight of sodium styrene sulfonate and 35 parts by weight of deionized water into the reactor, and stir to dissolve;

[0050] S2: Dissolve 5 parts by weight of sodium styrene sulfonate in 15 parts by weight of deionized water, and add it to the head tank 1;

[0051] S3: Add 15 parts by weight of hydrogen peroxide (27.5% content) into the head tank 2;

[0052]S4: Add 10 parts by weight of glutamic acid, 25 parts by weight of succinic anhydride, and 0.01 parts by weight of vanadium pentoxide to the reaction kettle in sequence, stir and mix evenly, heat up to 110-115°C and reflux for 1.5h, then cool down to 105- 110°C;

[0053] S5: slowly drop the sulfonate solution in the head tank 1 and the initiator in the head tank 2 into the reactor, and continue to react for 2 hours after the drop addition is completed to obtain the multi-component copo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com