Method and equipment for vaporizing full flash distillation of sodium aluminate liquor in technique for producing alumina

A technology of sodium aluminate and alumina, which is applied in the preparation of alumina/aluminum hydroxide, alkali metal aluminate/alumina/aluminum hydroxide, etc., which can solve the problems of high steam consumption, high equipment price and low equipment operation rate and other problems, to achieve the effect of reducing engineering investment, good economic benefits, and simplifying the evaporation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

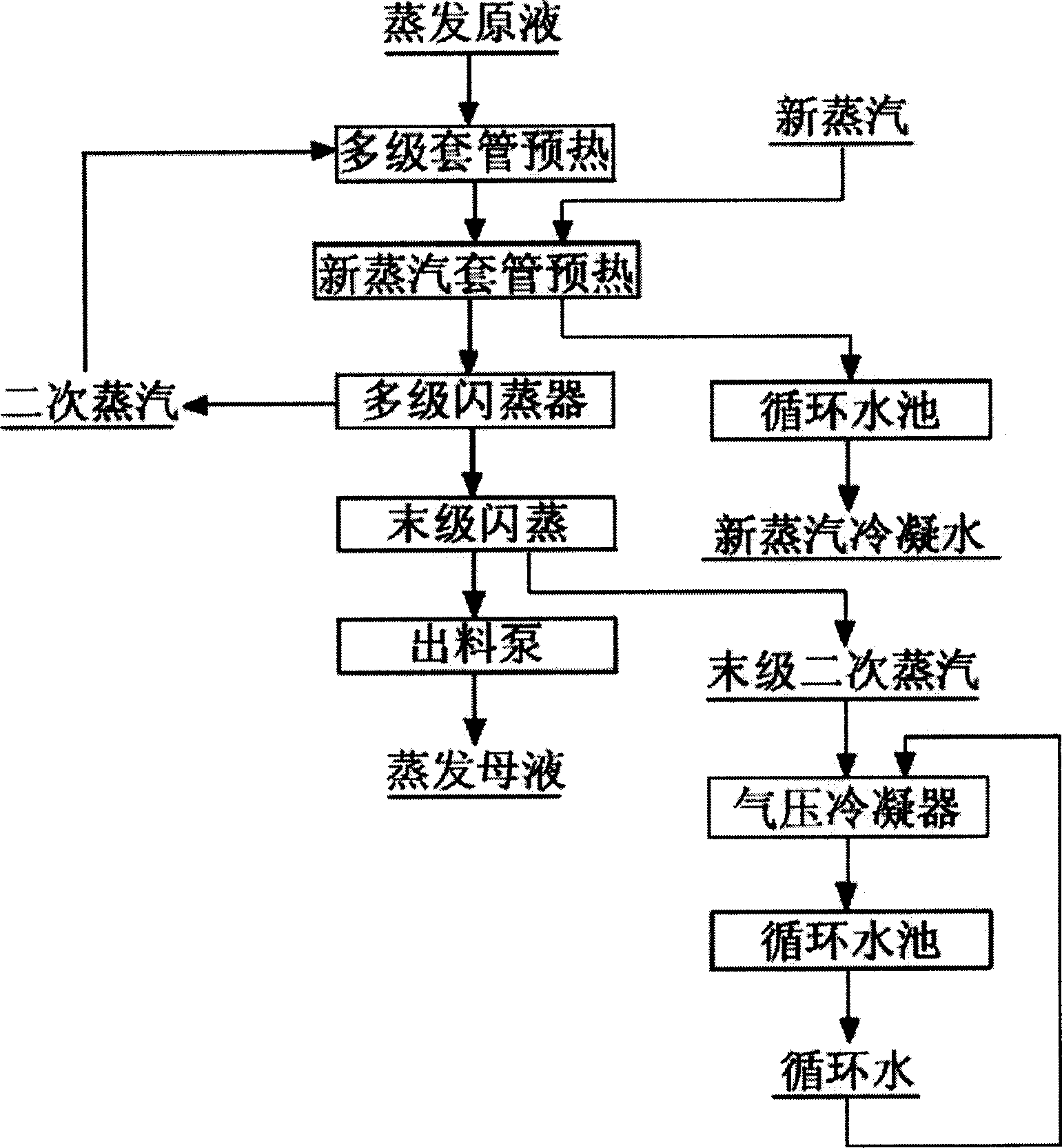

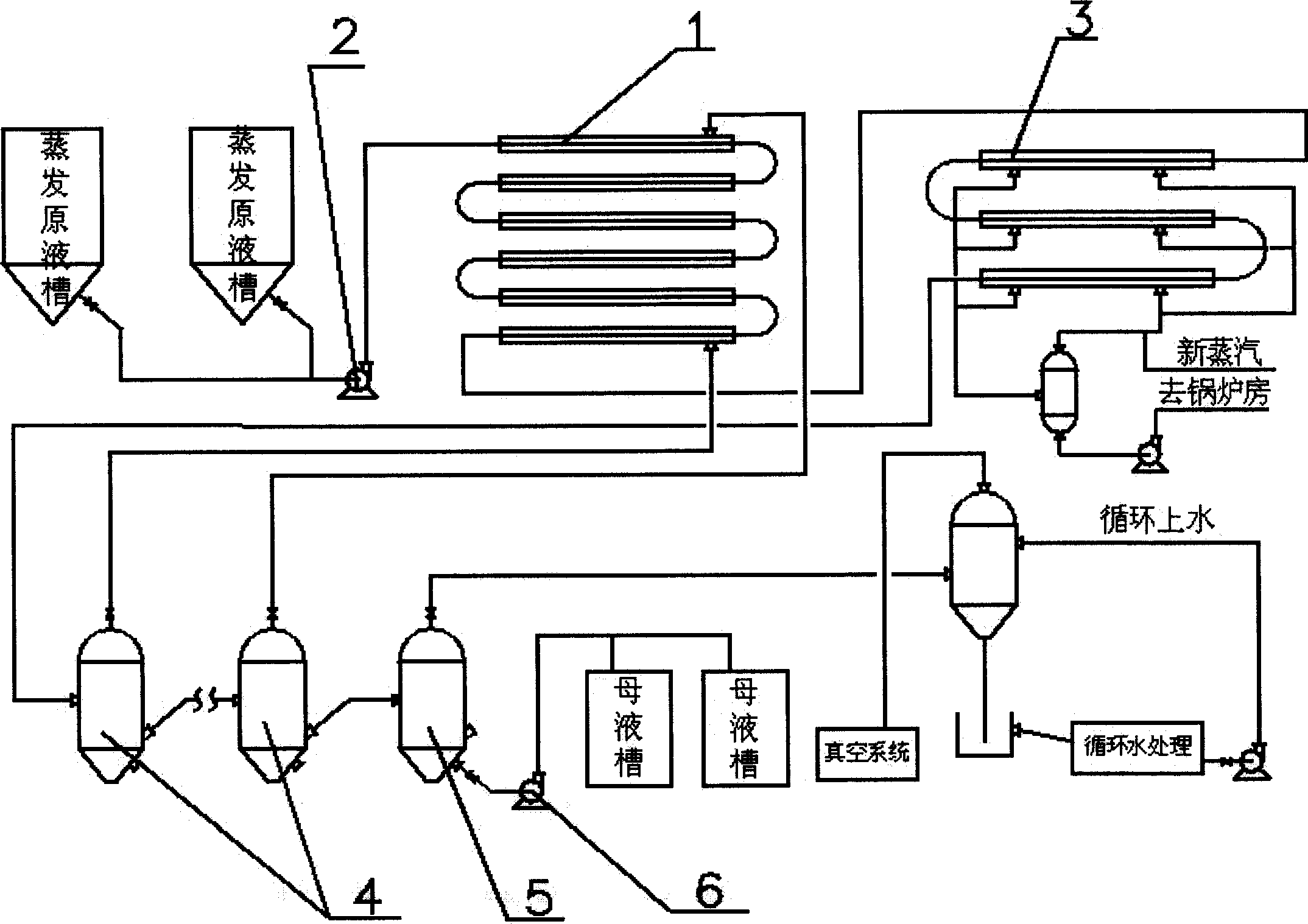

[0031] Embodiment 1 of the present invention: the evaporated stock solution from the evaporated stock solution tank has a temperature of 75 to 90° C., and is sent into the multi-stage casing preheater 1 with a centrifugal pump 2 (single-stage or cascade pump). The multi-stage casing preheater 1 is composed of 5-9 stages of preheating sections, and uses the secondary steam generated by the multi-stage flash evaporator 4 to preheat the evaporated stock solution, preheating the evaporated stock solution from 75-90°C to 130-170°C , the second section of new steam casing preheater 3 uses new steam to heat the evaporated stock solution, and preheats the evaporated stock solution from 130 to 170°C to 160 to 200°C. The flow rate of the evaporation raw liquid in the multi-stage casing preheater 1 is 1.8-2.8m / s. According to the size of the material flow, the multi-stage casing preheater 1 can be designed in two forms: single casing or multiple casings. In order to ensure the heat trans...

Embodiment 2

[0032] Embodiment two of the present invention: for the gibbsite alumina plant, the evaporation stock solution Na from the evaporation stock solution tank 2 o K 154g / l, temperature 85°C, a single centrifugal pump 2 is used to feed the multi-stage casing preheater 1, the casing preheater is a three-inner tube inner tube specification φ150, each pump corresponds to one inner tube for feeding, multi-stage The casing preheater 1 uses the first stage of secondary steam to preheat the evaporated raw liquid to about 145°C, and then uses new steam to preheat it to 180°C, and then sends it to the 7-stage flash evaporator 4, and flashes step by step to 92°C, sent to the evaporation mother liquor tank. Caustic Na for evaporating mother liquor 2 o K The concentration is 180-185g / l, which just meets the batching requirements of circulating mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com