Water conveyance tunnel with prestressed composite lining for shield tunnelling

A technology for composite lining and water delivery tunnels, applied in tunnel lining, shaft lining, drainage, etc., can solve problems such as narrow construction space, long lines, and harsh construction conditions, and achieve project investment savings, obvious social benefits, and significant engineering benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

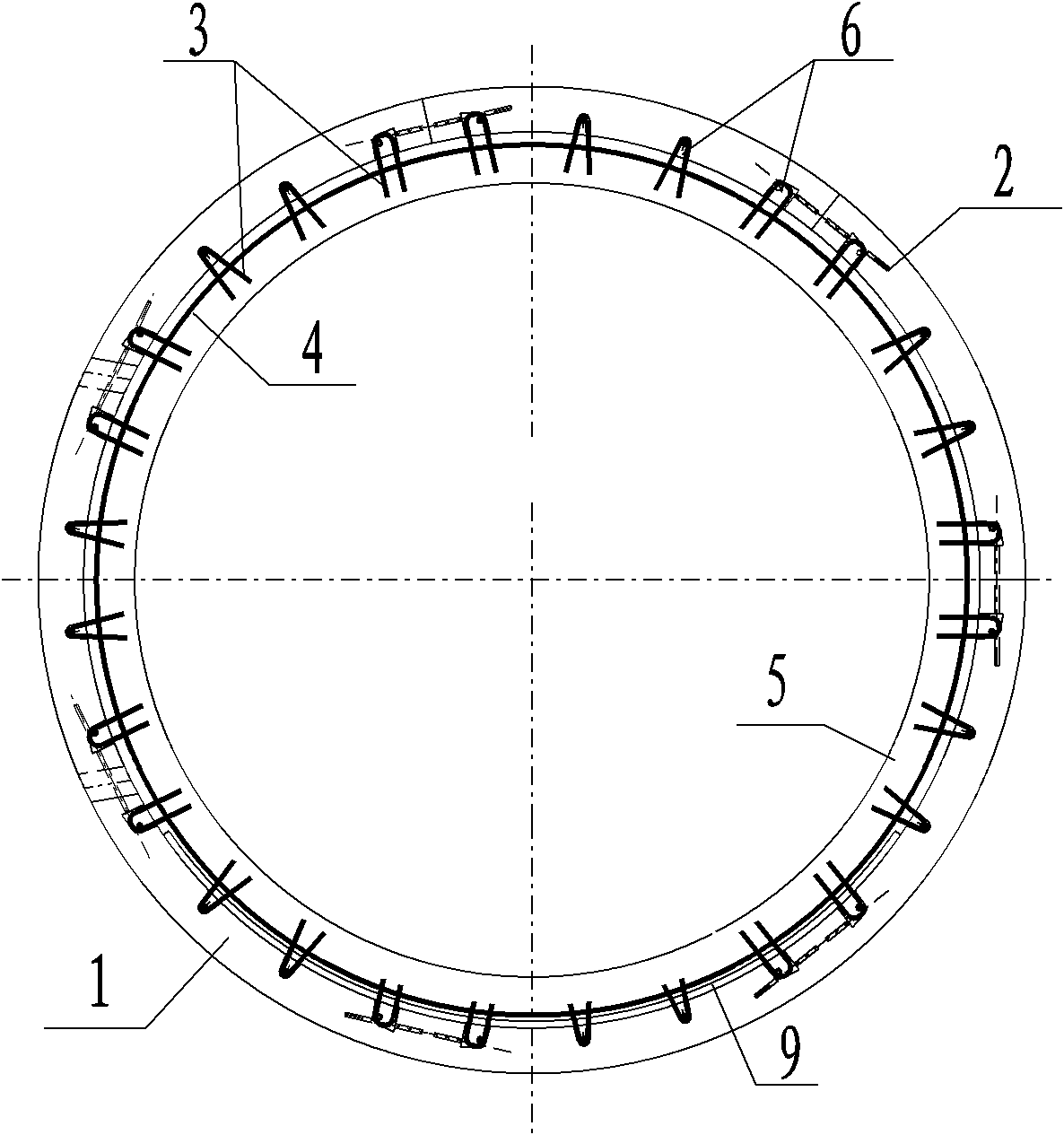

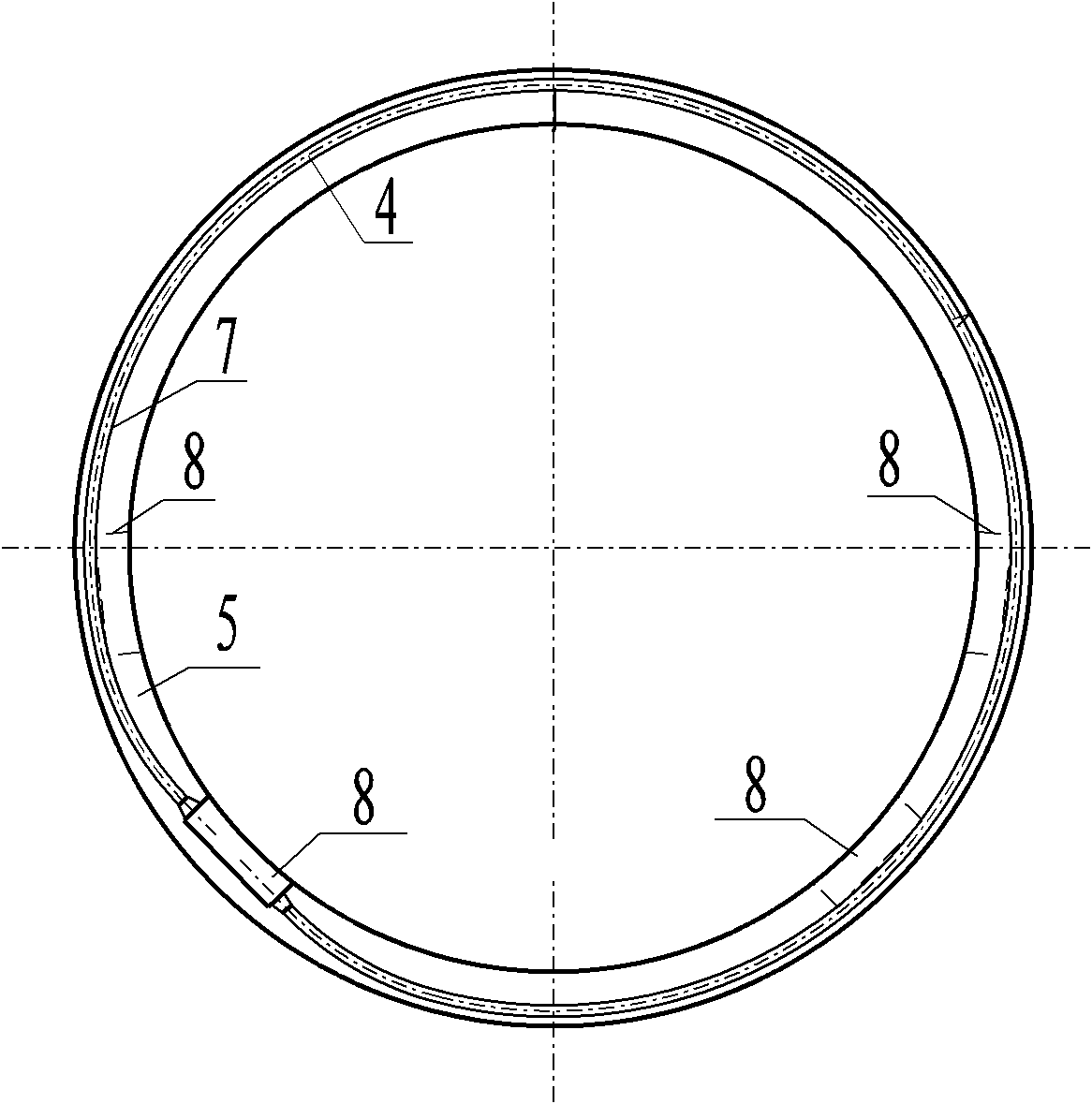

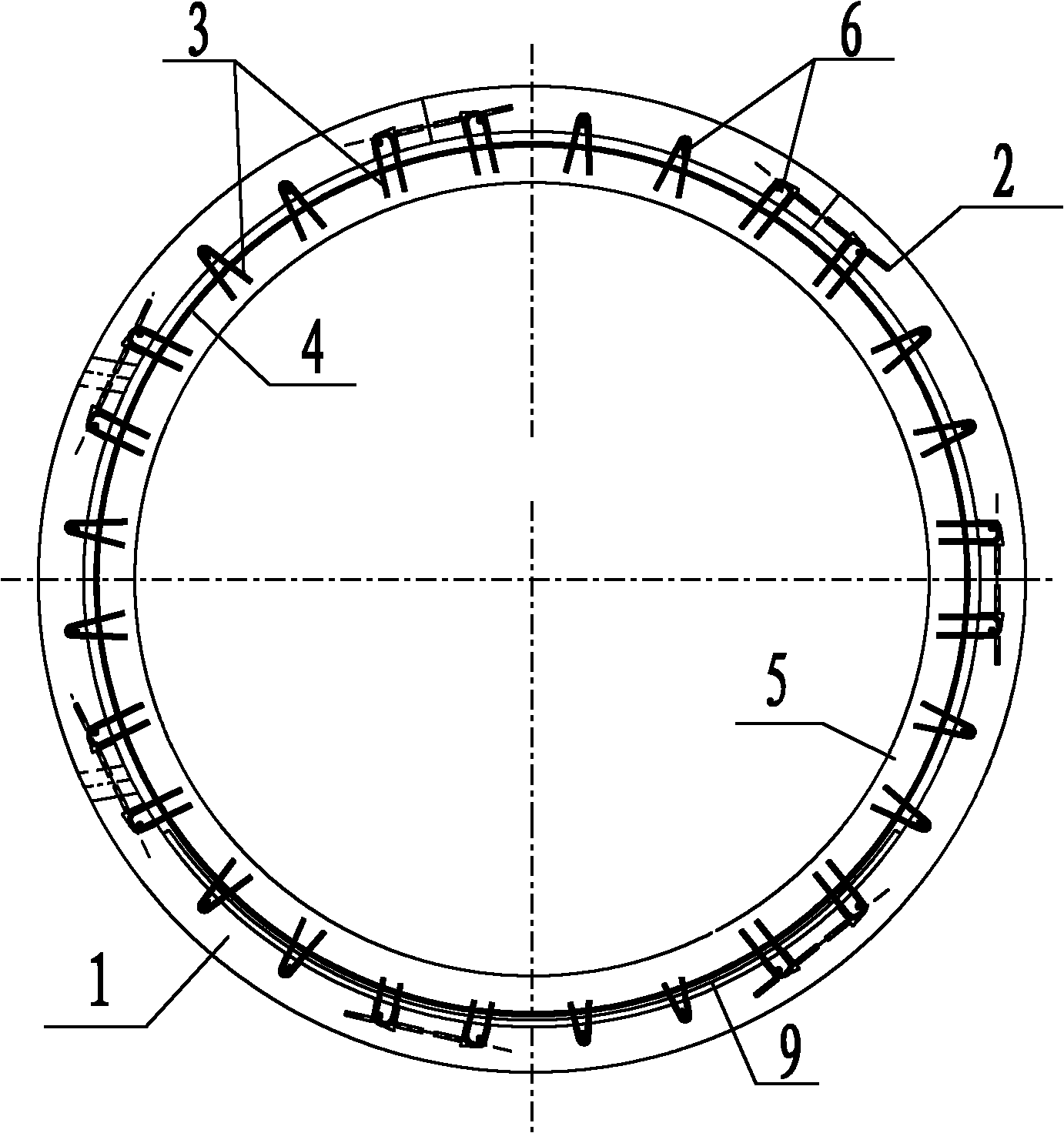

[0021] refer to figure 1 , figure 2 It can be seen that: the shield tunnel prestressed composite lining water delivery tunnel of the present invention includes the assembled segment ring formed by the shield method construction as an ordinary reinforced concrete outer lining 1, and each segment segment of the same ring is connected by connecting bolts 2. Insert ribs 3 are installed on the hand holes of the segment ring, and concrete is poured directly on the outer lining 1 to form the inner lining 5 and concrete shear keys 6, thereby forming a composite lining structure; the inner lining 5 has a pre-buried tunnel 7, and the There are anchor cables 4 ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com