Detection apparatus and method of chemical mechanical polishing conditioner

a detection apparatus and polishing conditioner technology, applied in the direction of automatic grinding control, metal-working apparatus, abrasive surface conditioning devices, etc., can solve the problems of doubtful detection results of the well-known method, waste of energy and time of people on the well-known methods, etc., to avoid scratches and breakages produced on the polishing pad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0032]Please refer to FIG. 4, a flow diagram of the detection apparatus of the chemical mechanical polishing conditioners of the present invention is shown. The detection apparatus of the chemical mechanical polishing conditioners are substantially the same as the above Example 1, except that removing the risk diamonds to the specified location by the mobile platform in example 1 is different. In example 2, the risk diamonds are removed directly to the specified location by the placement base on the detection apparatus itself.

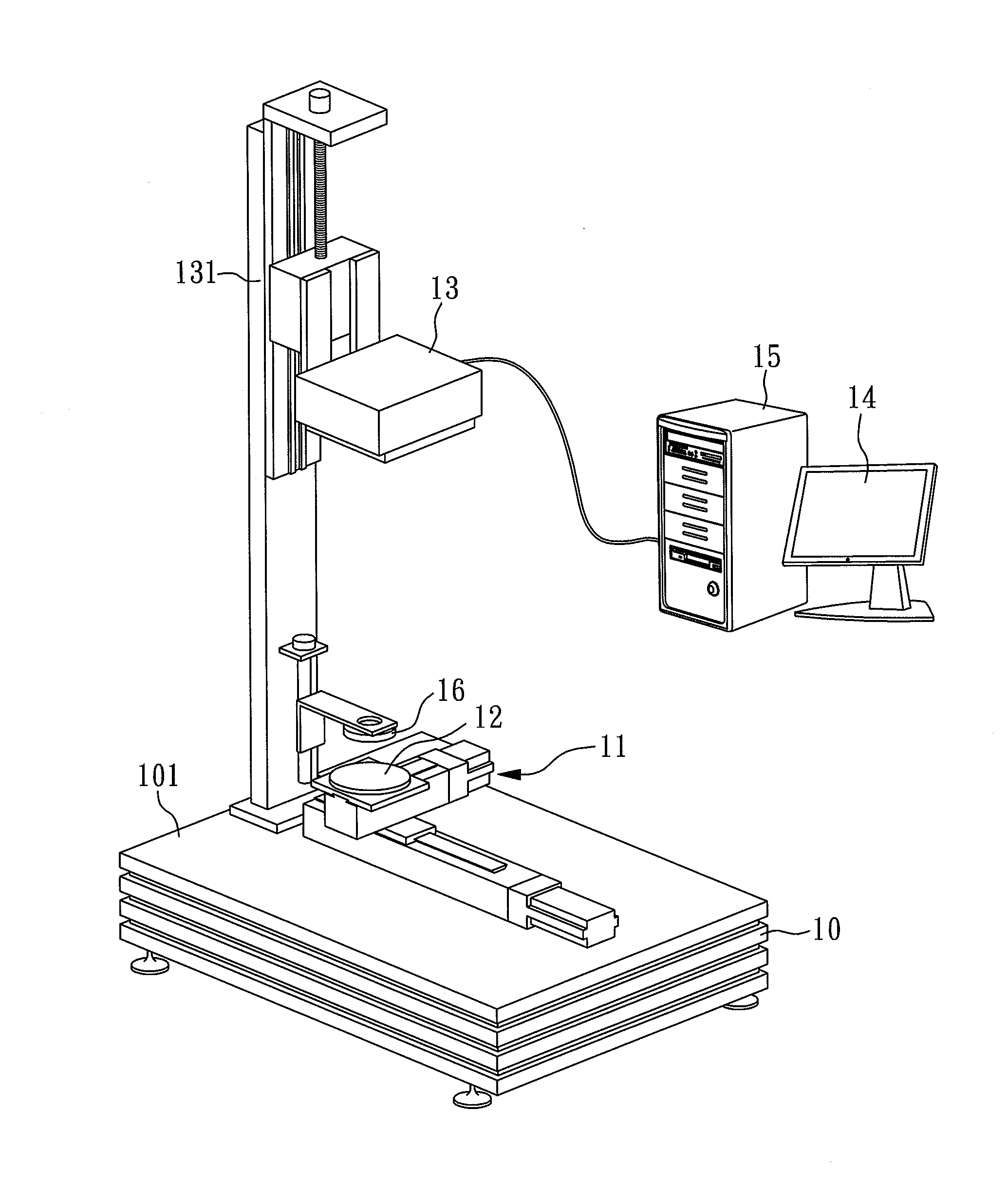

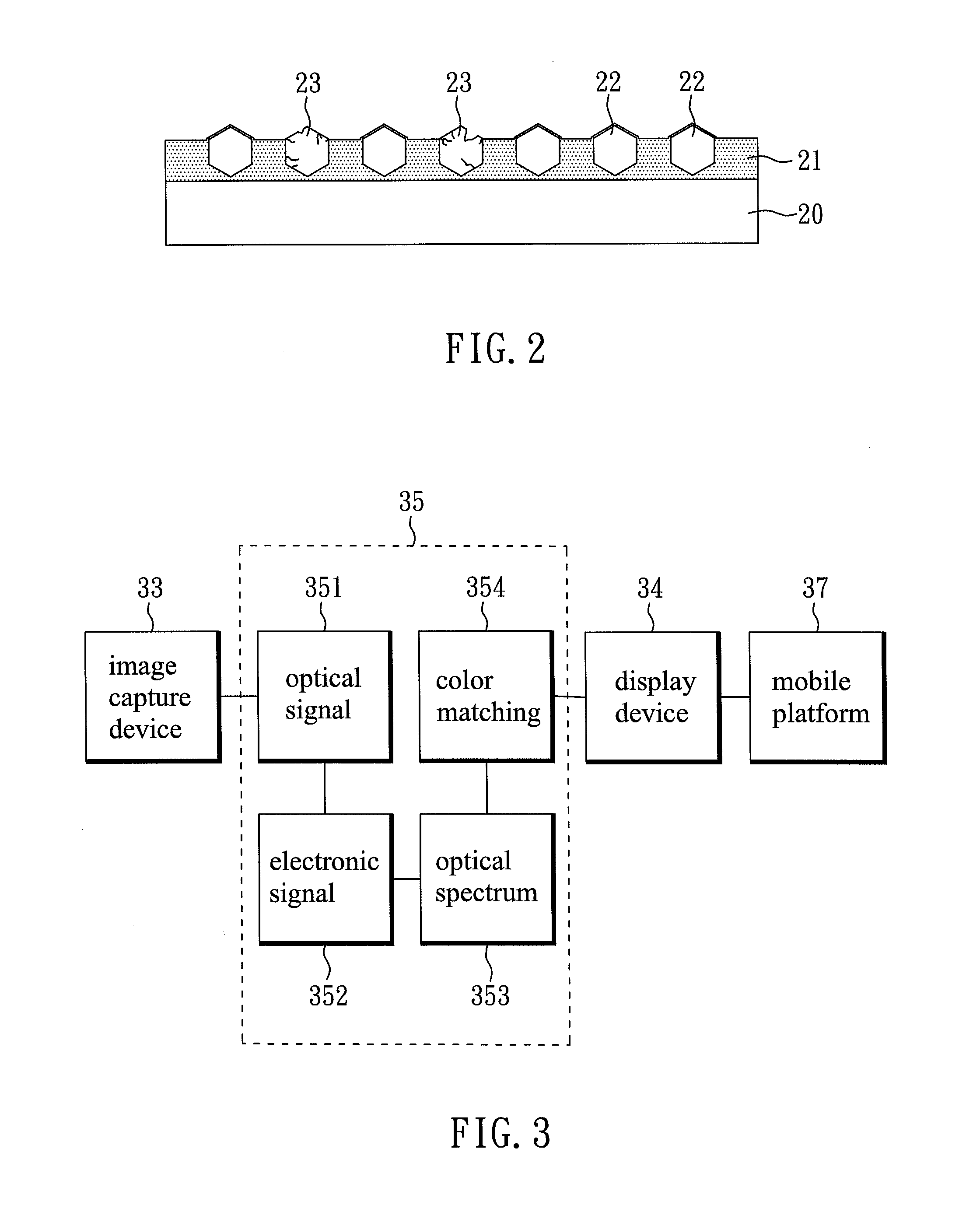

[0033]As shown in FIG. 4, when the detection apparatus of the chemical mechanical polishing conditioner is operated (referring to FIG. 1 simultaneously), the chemical mechanical polishing conditioner to be detected is disposed on the placement base, and one or a plurality of captured images on different regions are formed by the image capture device 43. Further, the captured images are transmitted into the image recognition module 45, so that the optical signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com