Cathode including insulation layer on cathode tab and secondary battery including the cathode

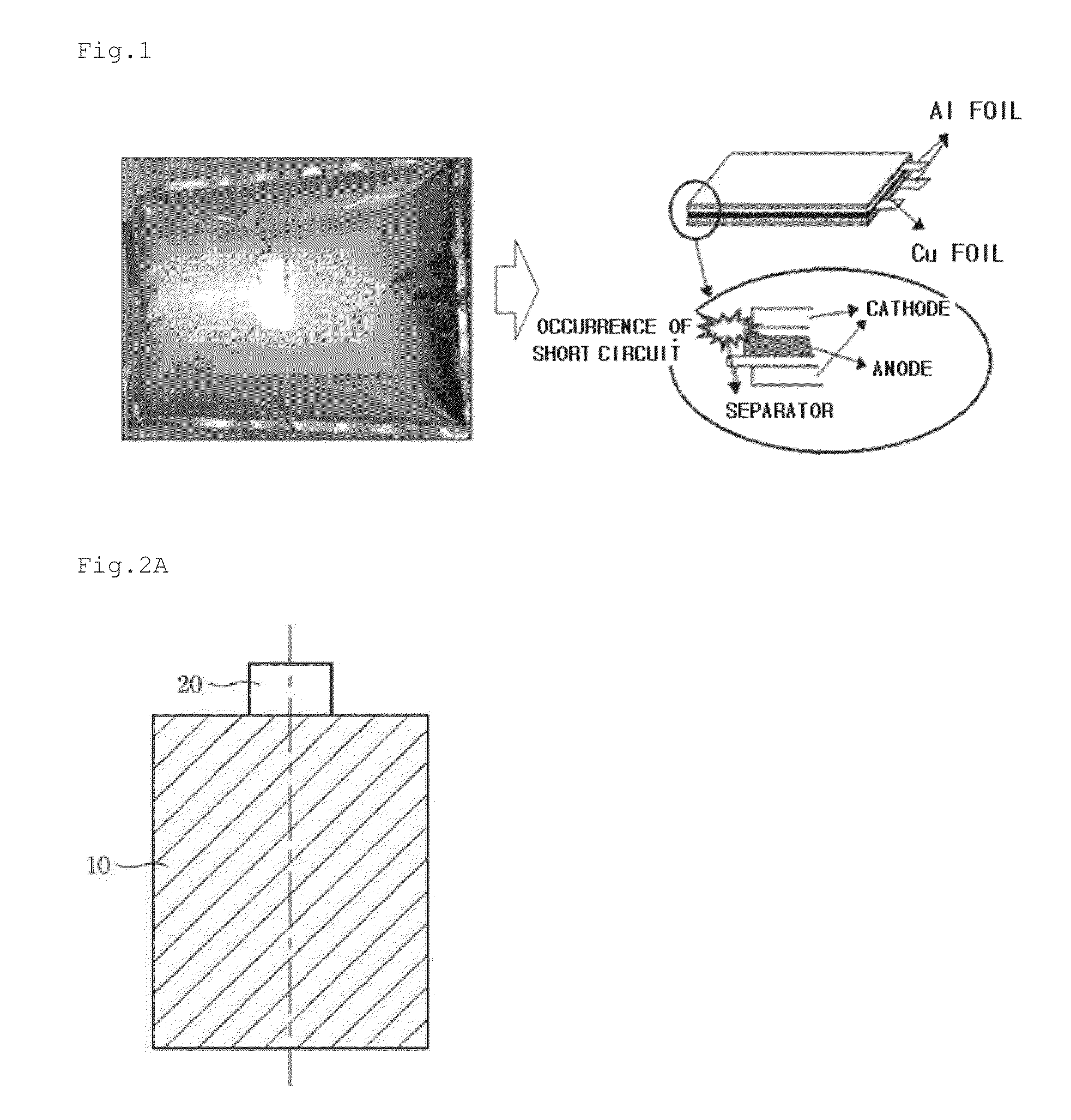

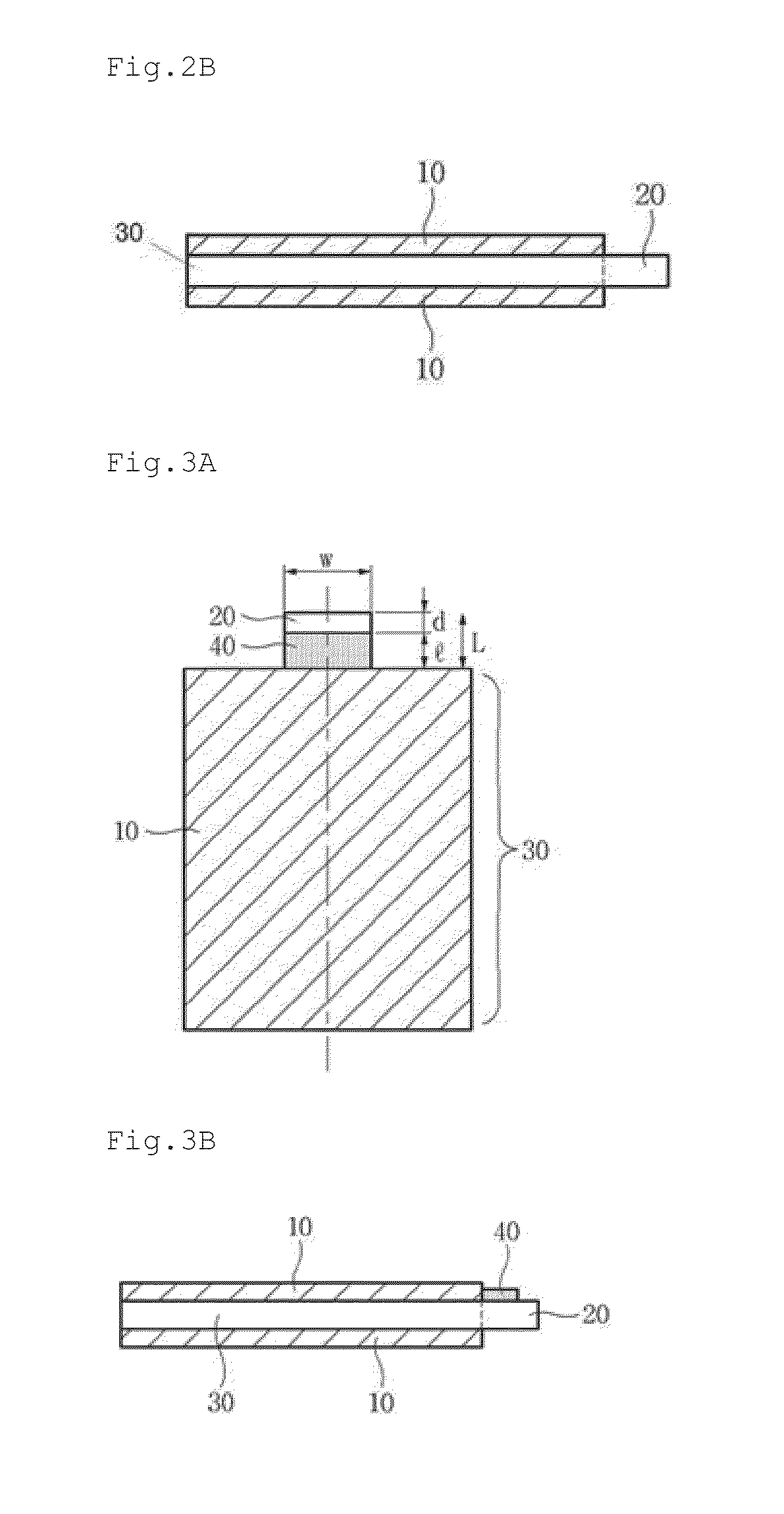

a cathode and cathode tab technology, applied in the manufacture of electrodes, cell components, cell component details, etc., can solve the problems of excessive deformation of the battery, limited use of a typical separator alone under abnormal misuse or abuse conditions, and insufficient heat resistance properties, so as to achieve significant improvement in safety and reliability of battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]Hereinafter, the present invention will be described in more detail to allow for a clearer understanding of the present invention.

[0021]It will be understood that words or terms used in the specification and claims shall not be interpreted as the meaning defined in commonly used dictionaries. It will be further understood that the words or terms should be interpreted as having a meaning that is consistent with their meaning in the context of the relevant art and the technical idea of the invention, based on the principle that an inventor may properly define the meaning of the words or terms to best explain the invention.

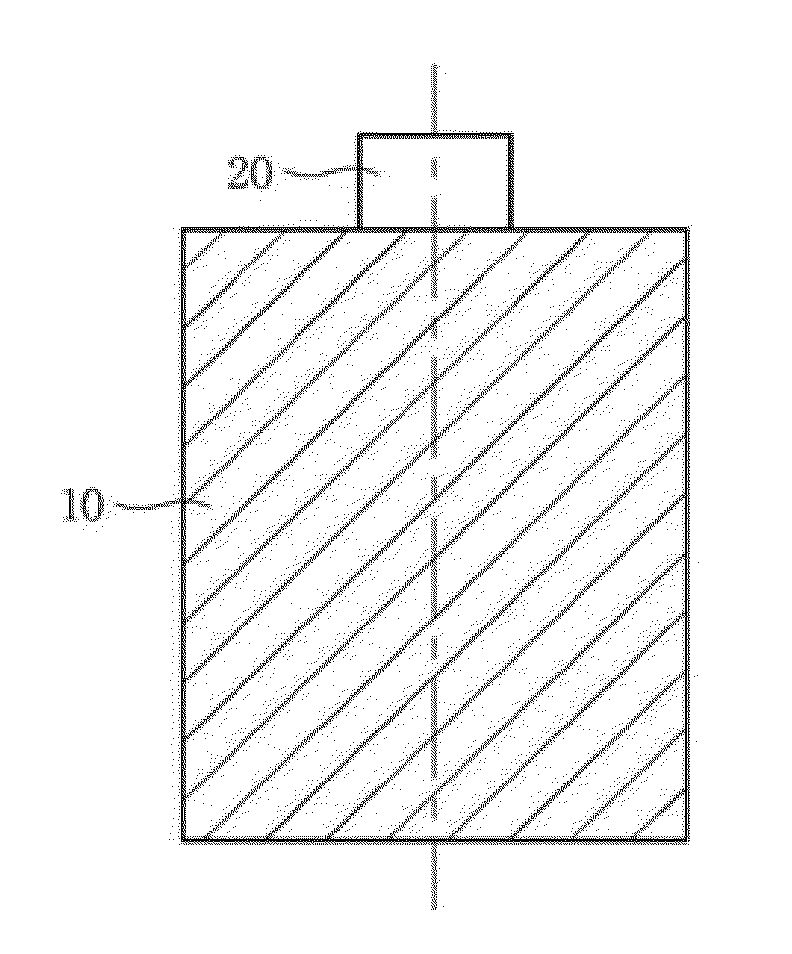

[0022]A cathode according to an embodiment of the present invention may include a cathode current collector, a cathode tab protruding from the cathode current collector, and an insulation layer coated with an insulating material on the cathode tab.

[0023]According to an embodiment of the present invention, since the cathode including the insulation layer on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| heat resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com