Heat transfer pipe for heat exchanger

a technology of heat exchanger and heat transfer pipe, which is applied in the direction of heat transfer modification, lighting and heating apparatus, tubular elements, etc., can solve the problems of increasing the roughness of the heat transfer pipe, increasing the manufacturing cost, etc., and achieves the effect of less resistance to fluids and improving the operating efficiency of the whole heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Hereinafter, particular embodiments of the heat transfer pipe for heat exchanger according to the invention are described in detail with references to the drawings.

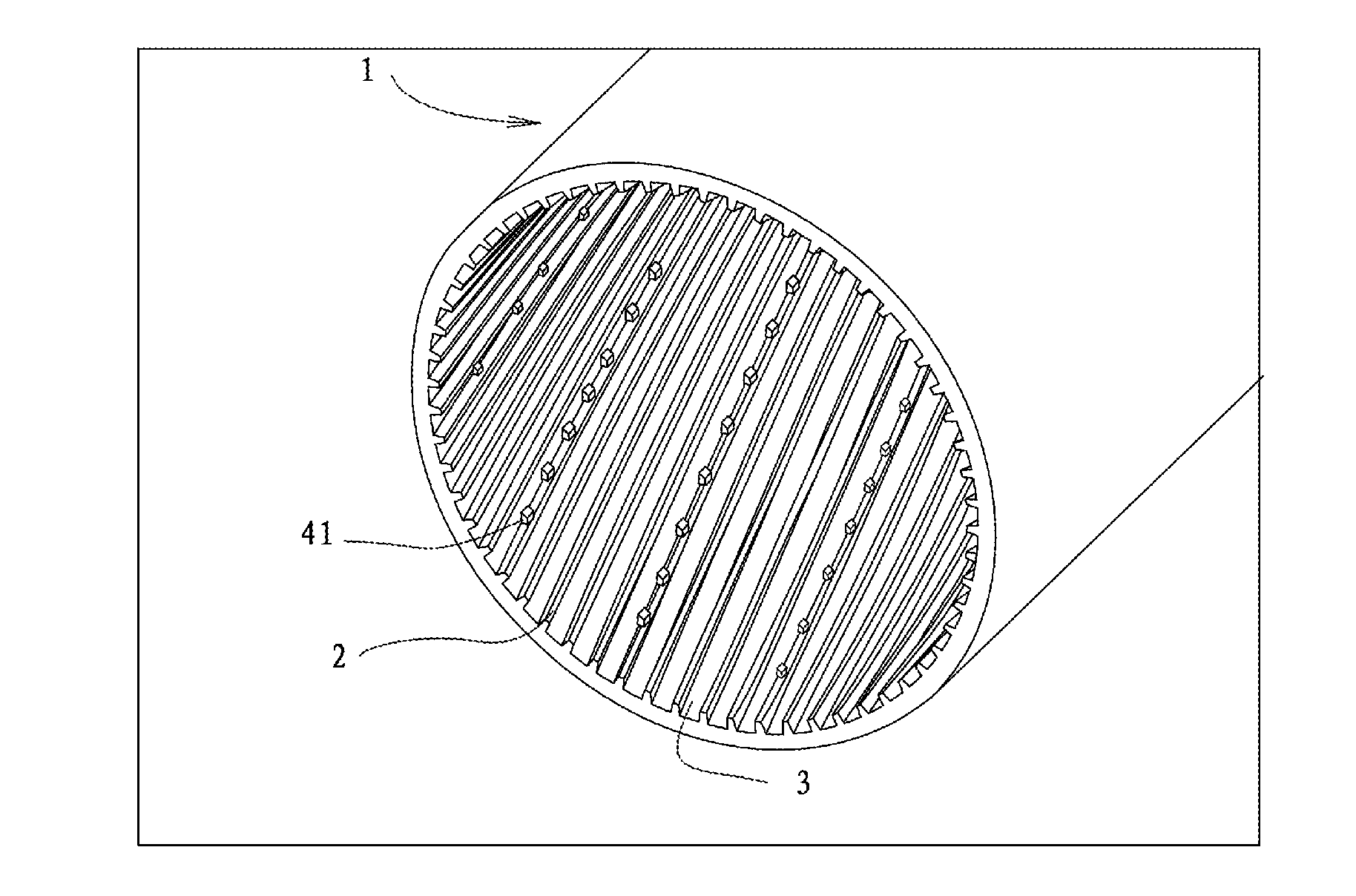

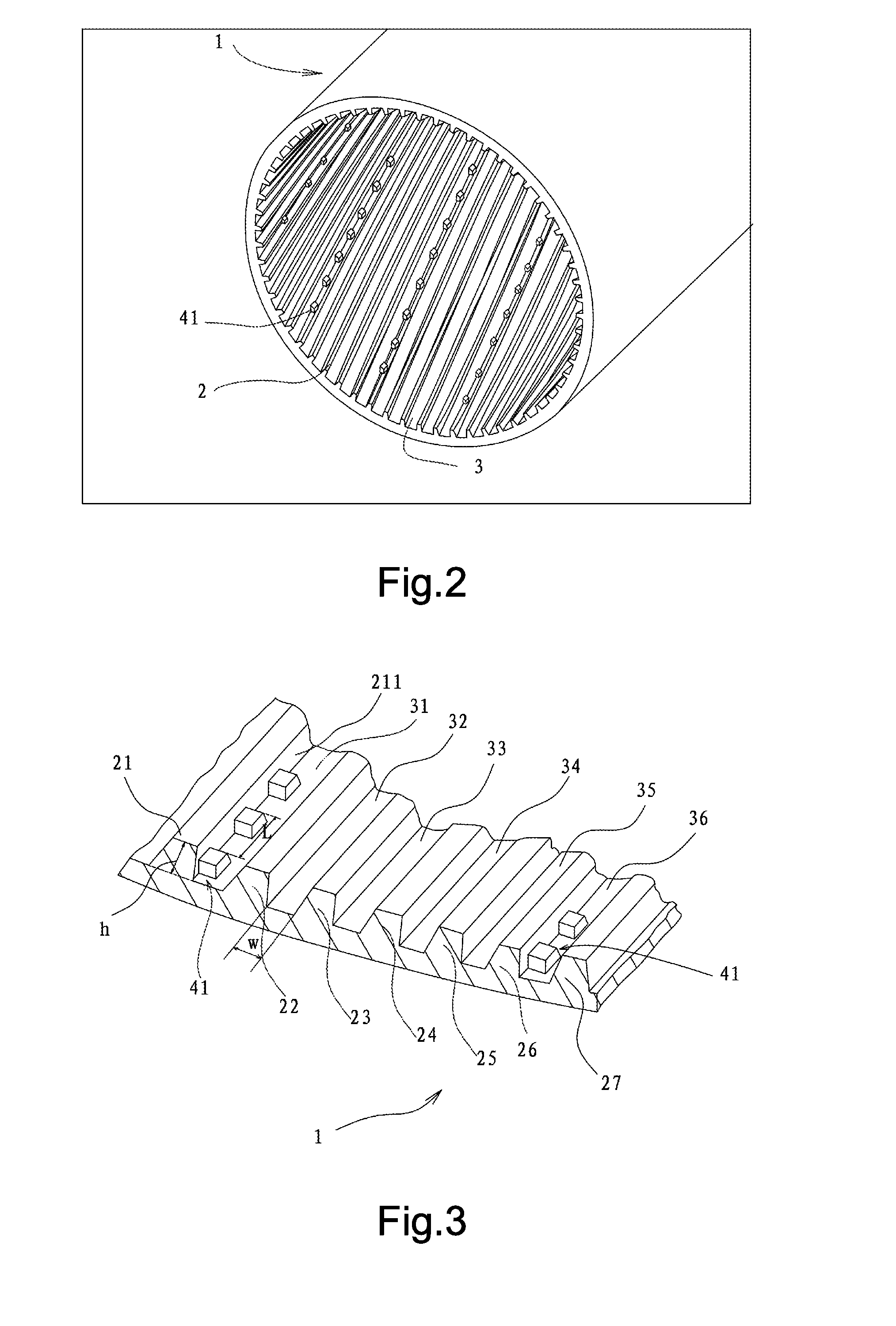

[0023]FIG. 2 shows a schematic perspective view of a part of a heat transfer pipe 1 according to the first embodiment of the invention. As shown in FIG. 2, the heat transfer pipe 1 is formed as a cylinder pipe, preferably of copper. Without doubt, the heat transfer pipe 1 can be made of other alloy materials. A plurality of helical primary teeth 2 are manufactured and formed in the inner surface of the heat transfer pipe 1 (particularly, shown as 21, . . . , 26, and 27 in FIG. 3). Accordingly, grooves 3 are formed between two adjacent primary teeth (particularly, shown as 31, 32, 33, 34, 35, and 36 in FIG. 3). Furthermore, protrusions 41 disposed intermittently and having heights lower than primary teeth are formed in some of the grooves 3. The protrusions further increase the roughness within the heat transfer pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com