Construction method for root-type foundation anchorage and bored, root-type cast in-situ pile with anchor bolts

a construction method and root-type technology, applied in the direction of caissons, constructions, building materials handling, etc., can solve the problems of high construction cost, cast-in-place piles have disadvantages, and increase the consumption of reinforcing steel bars and cement, so as to achieve simple construction technology, less material consumption, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

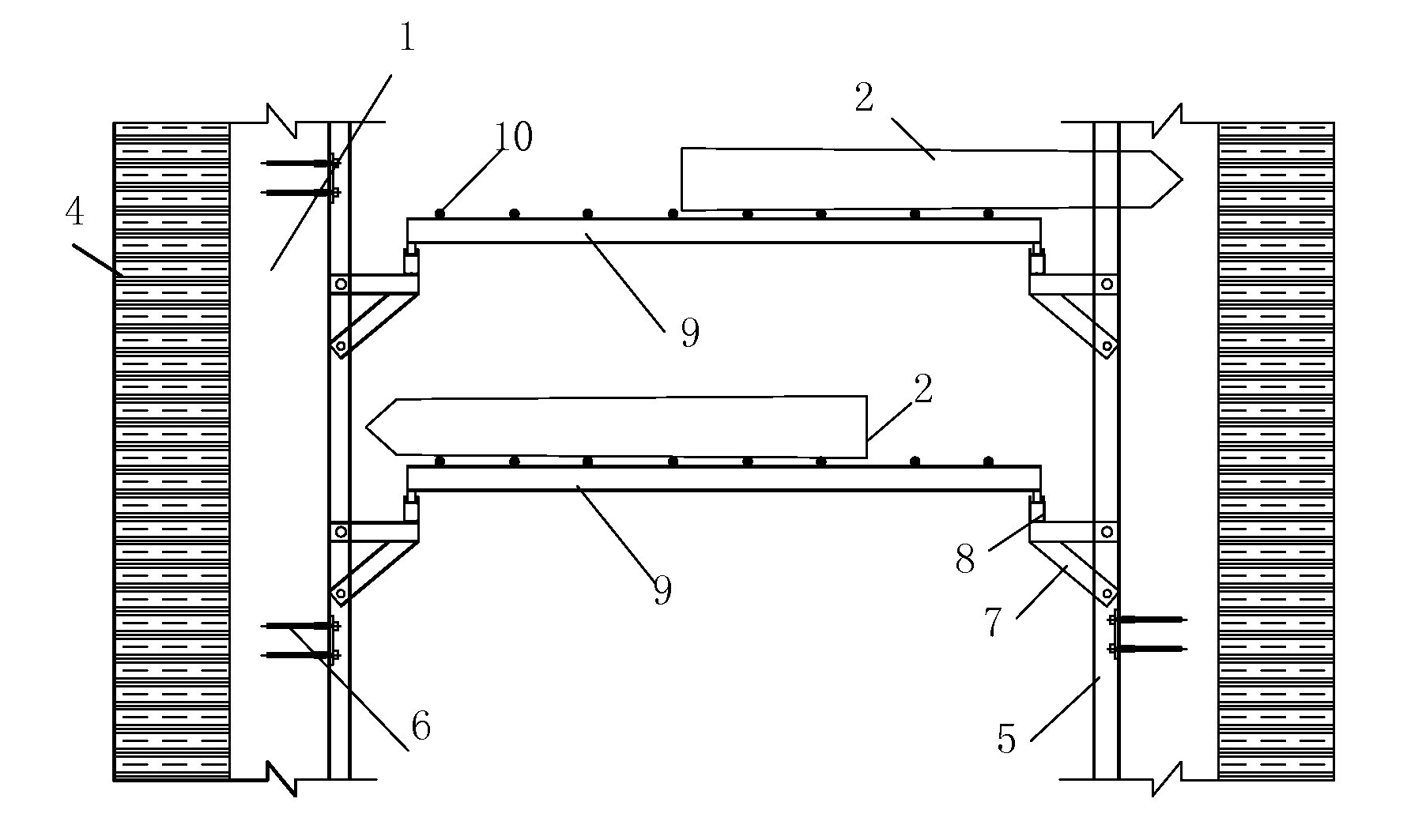

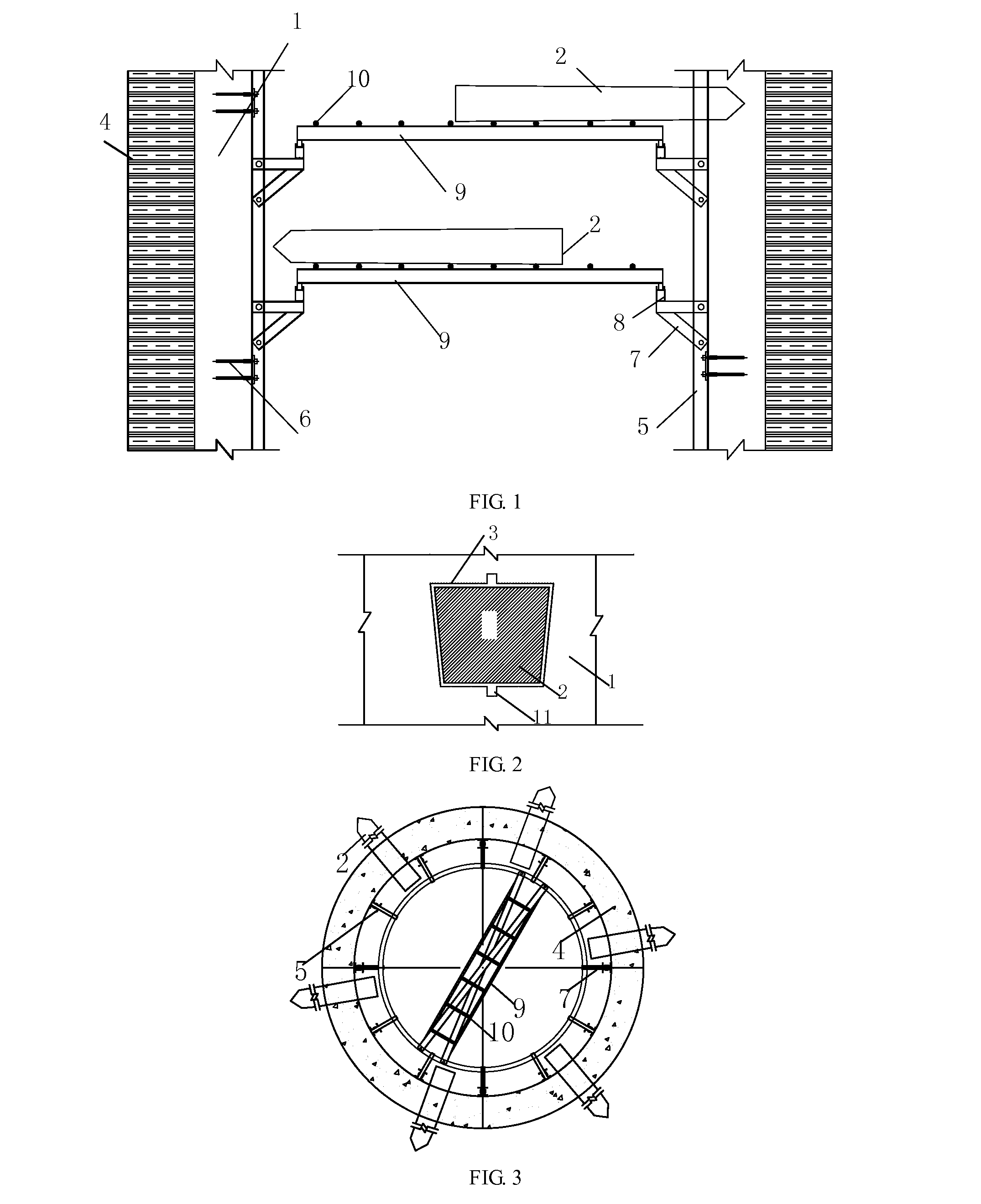

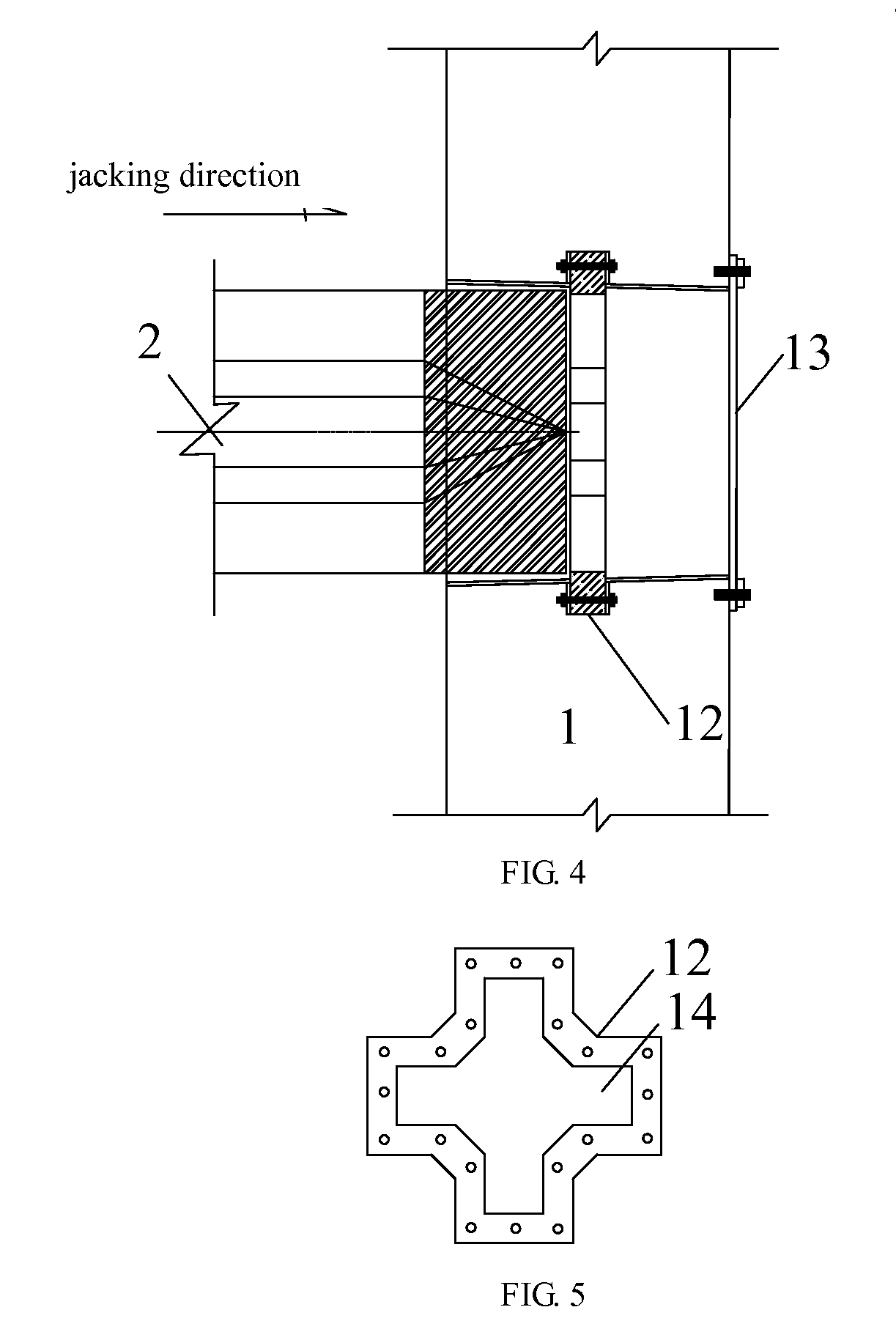

[0038]Just as shown in FIG. 1 and FIG. 3, the invention discloses a construction method for rooted foundation anchorage, comprising the following steps:

[0039]Precasting a bore hole 1 in sections, reserving in the wall of the bore hole holes 3 for the projection of anchor roots 2, and sinking the caisson into the earth 4 by its self-weight, which stops sinking when the bottom runs into rocks; the anchor root has a cusp at one end, and a flat head at the other end;

[0040]Cleaning the bottom of the bore hole, and sealing the bottom with concrete;

[0041]Precasting the beam type concrete roots and, within the bore hole, projecting the roots into the earth around the caisson 4;

[0042]And sealing a concrete cover over the bore hole to form a flat cap, which can be used as the cap of a bridge foundation.

[0043]The precast beam type concrete roots are, within the bore hole, projected in to the earth, comprising the following steps:

[0044]The inwall of the caisson is internally provided with a ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com