Method for in situ coating a tower solar receiver

a technology of solar receiver and in situ coating, which is applied in the direction of solar heat collector safety, light and heating apparatus, coatings, etc., can solve the problems of difficult curing of the curing process, the product has presented durability problems, and the documentation that can be found about the experience of coating application methodology, in combination with the use of solar technology, is still scarce, and the effect of reducing the cost of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

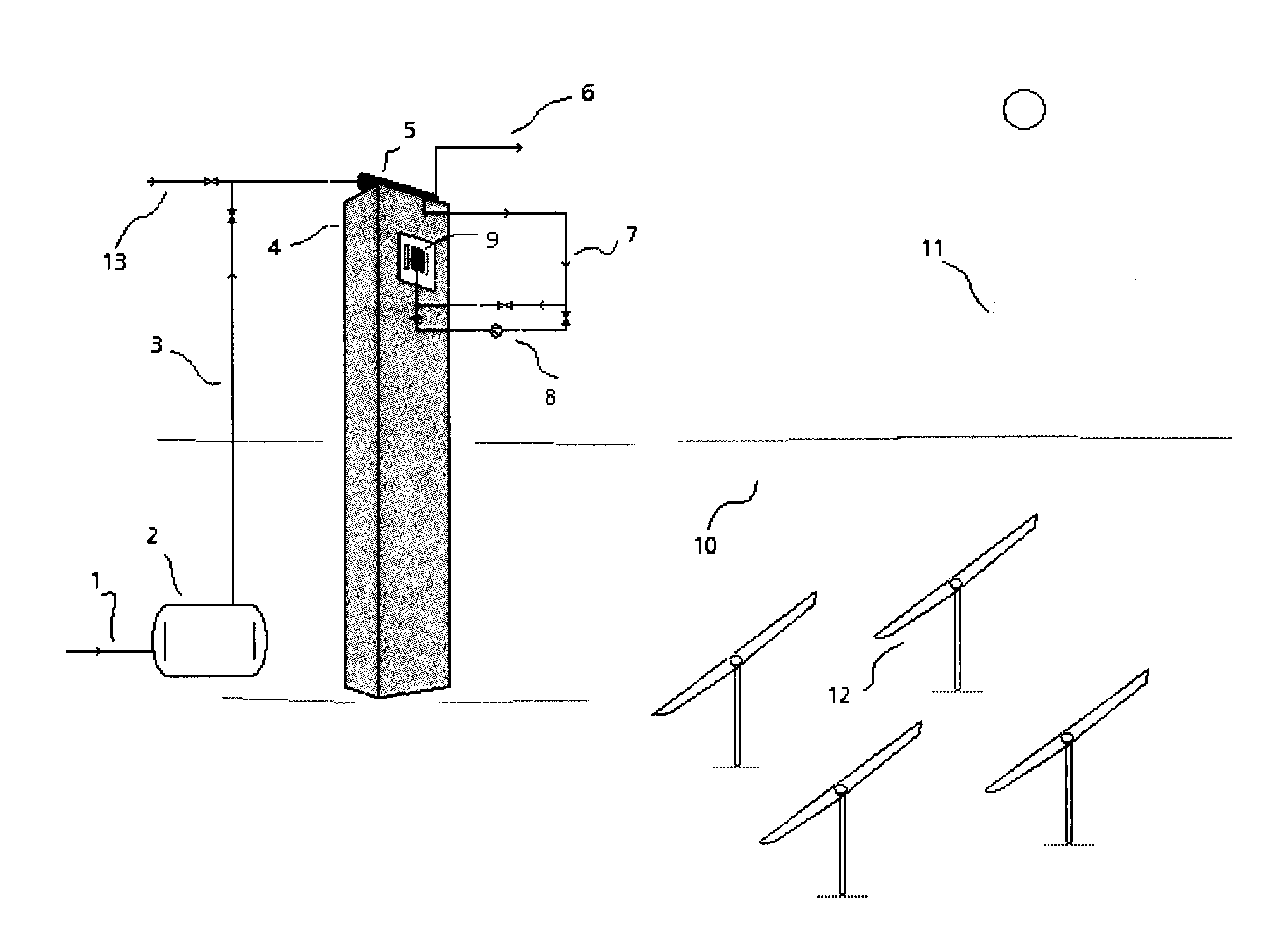

[0013]Tower solar receivers receive concentrated solar radiation by means of a heliostat field. These receivers, through which a heated working fluid circulates, require the application of an absorbing coating on their surfaces. This coating, in addition to increasing the absorptivity of the surface, also protects the receiver against environmental factors and corrosion.

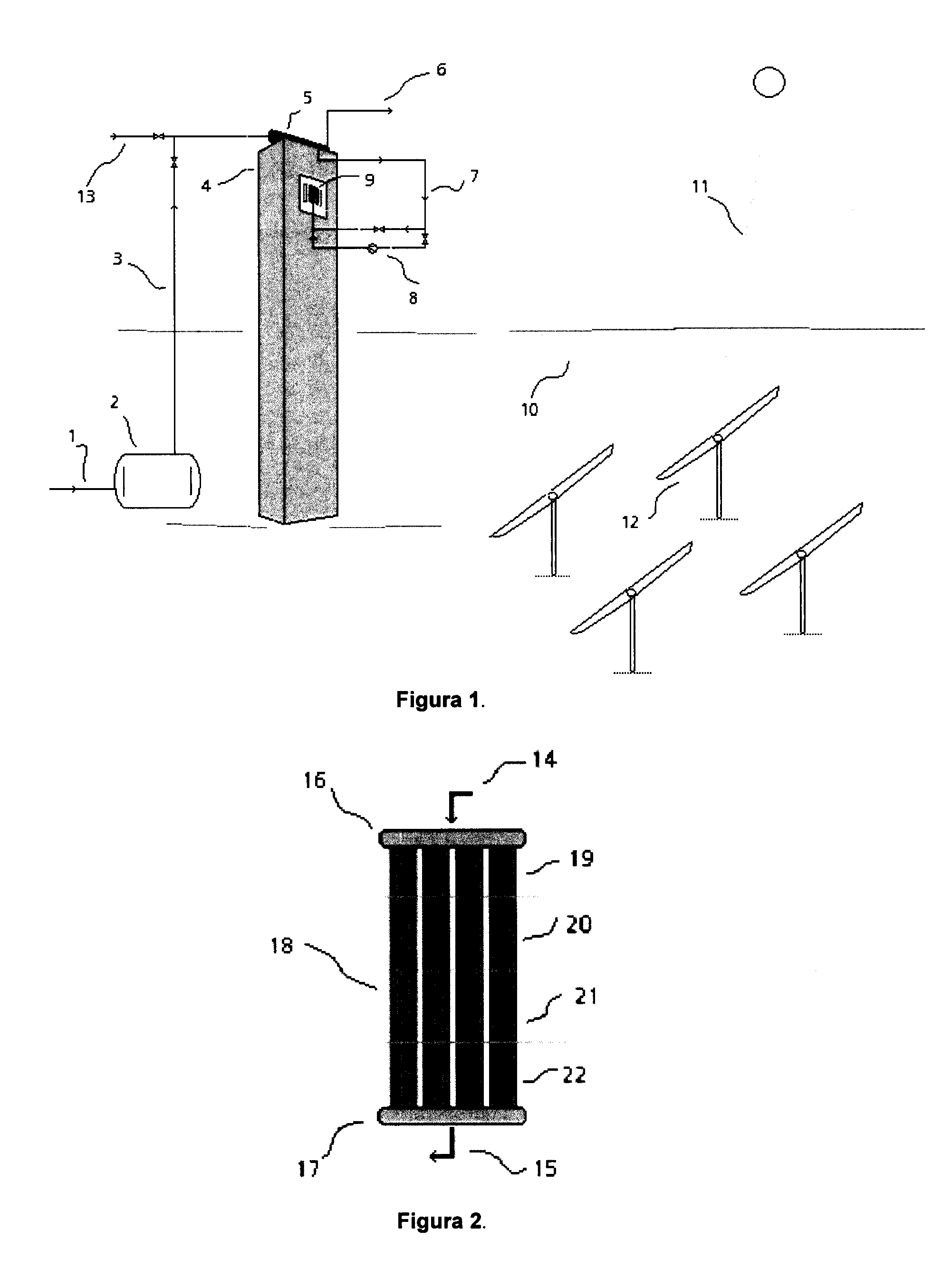

[0014]The absorbing coatings currently used in the receivers are silicon-based coatings, which provide them with good resistance to high temperatures, having black pigments that grant the absorbing property.

[0015]Due to the fact that the protection of a surface with a coating depends on the surface preparation and on the success of the deposition process (thickness of the deposited film, continuity thereof, application method), in addition to the characteristics of the product itself, the methodology to be used in all the steps of the application process needs to be specified.

[0016]The solution to the low durability ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com