Hybrid vertical drainpipe heat exchanger

a heat exchanger and drainpipe technology, applied in the direction of indirect heat exchangers, stationary tubular conduit assemblies, lighting and heating apparatus, etc., can solve the problems of limited length of vertical installations and limit the wetted surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

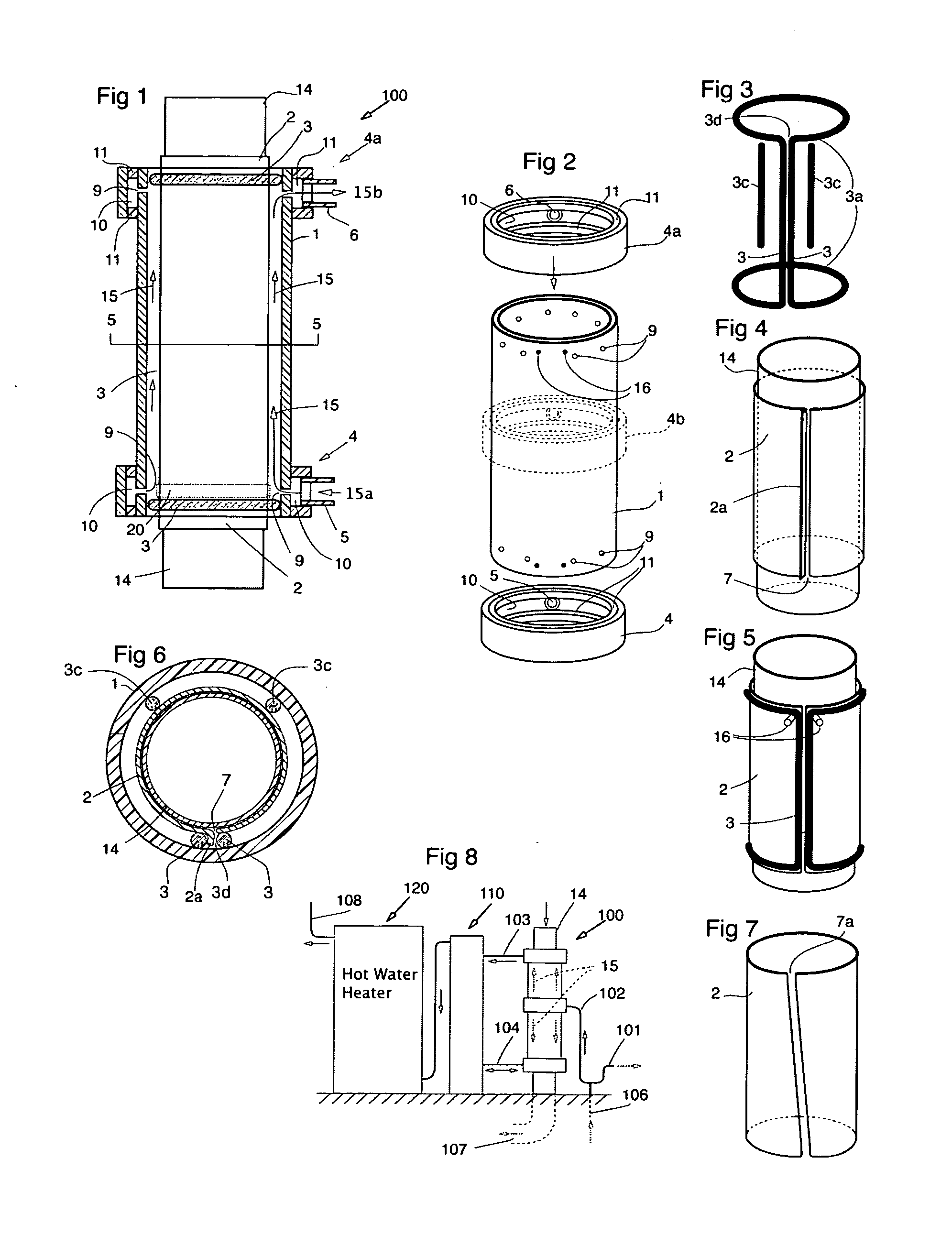

[0021]Referring to the drawings, FIG. 1 shows a cross section of the drainpipe heat exchanger 100. The central drainpipe 14 may be a common copper DWV (domestic waste vent) tube or pipe of any suitable diameter from, say, 2 to 6 inches. It may also be rolled and seamed from any suitable sheet material. In FIGS. 1 and 2 outer tube 1 may be of any suitable still material such as a PVC or ABS plastic tube or pipe capable of withstanding pressure from within and sized in accordance with the diameter of drainpipe 14. Outer tube 1 has fluid openings adjacent each end preferably in the form of a ring of holes 9 through the wall for fluid distribution.

[0022]Inlet manifold 4 (lower) and outlet manifold 4a (upper) have inlet 5 and outlet 6 fittings (inlet flow 15a, outlet flow 15b) and an internal circumferential flow channels 10 that communicate with their respective distribution holes 9 in outer tube 1. As shown in FIG. 2 the manifolds arrows indicate they are to be slid on over each end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductor | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

| Distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com