Automatic polishing device for surface finishing of complex-curved-profile parts

a technology of complex-curved-profile parts and automatic polishing, which is applied in the direction of automatic grinding control, metal-working equipment, manufacturing tools, etc., can solve the problems of insufficient precision at acceptable efficiency, the use of these automated polishing machines is restricted to those parts, and the existing automated polishing machines cannot be applied to complex-curved-profile parts. , to achieve the effect of facilitating the flow of abrasive slurry, low cost and non-destructiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

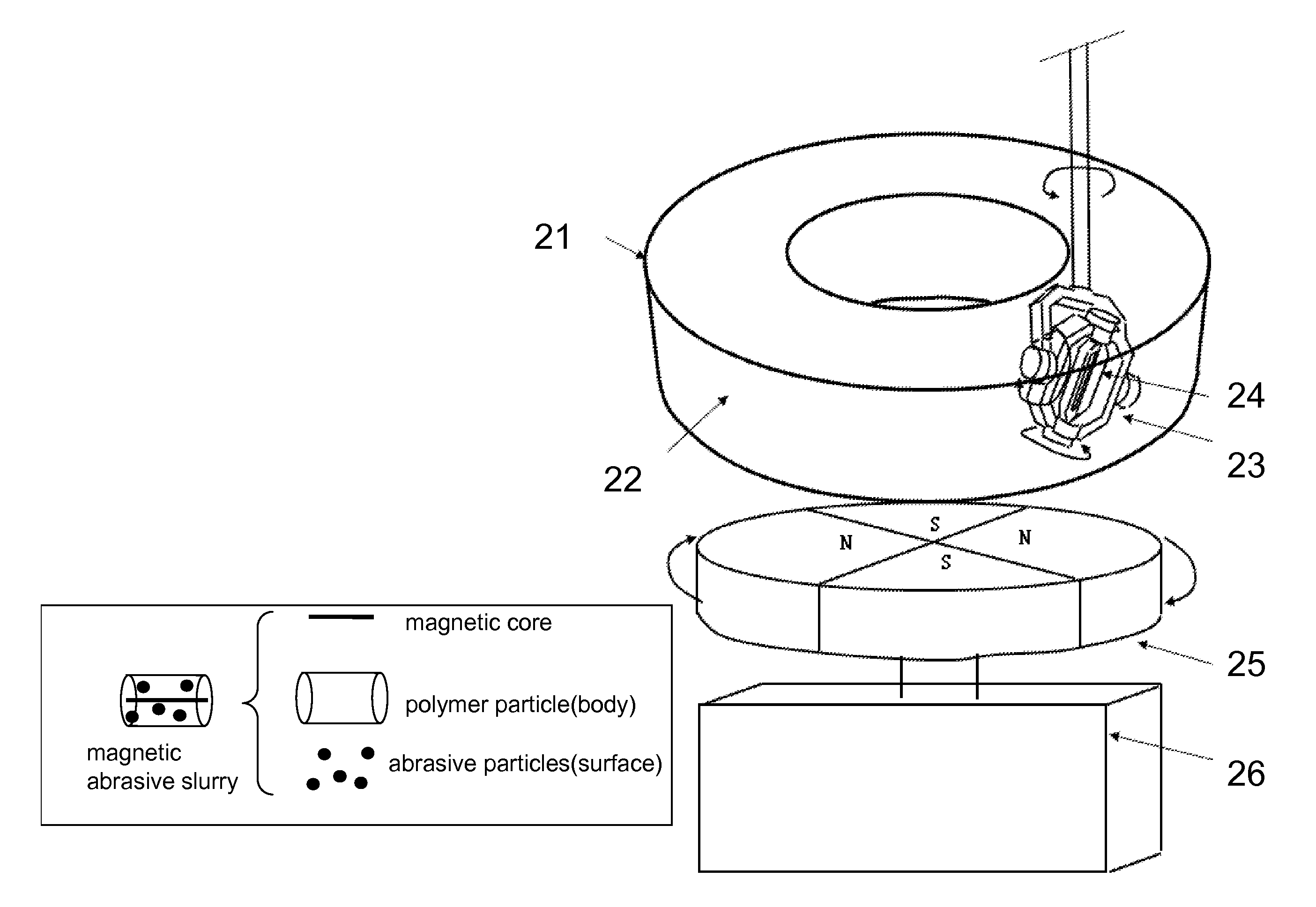

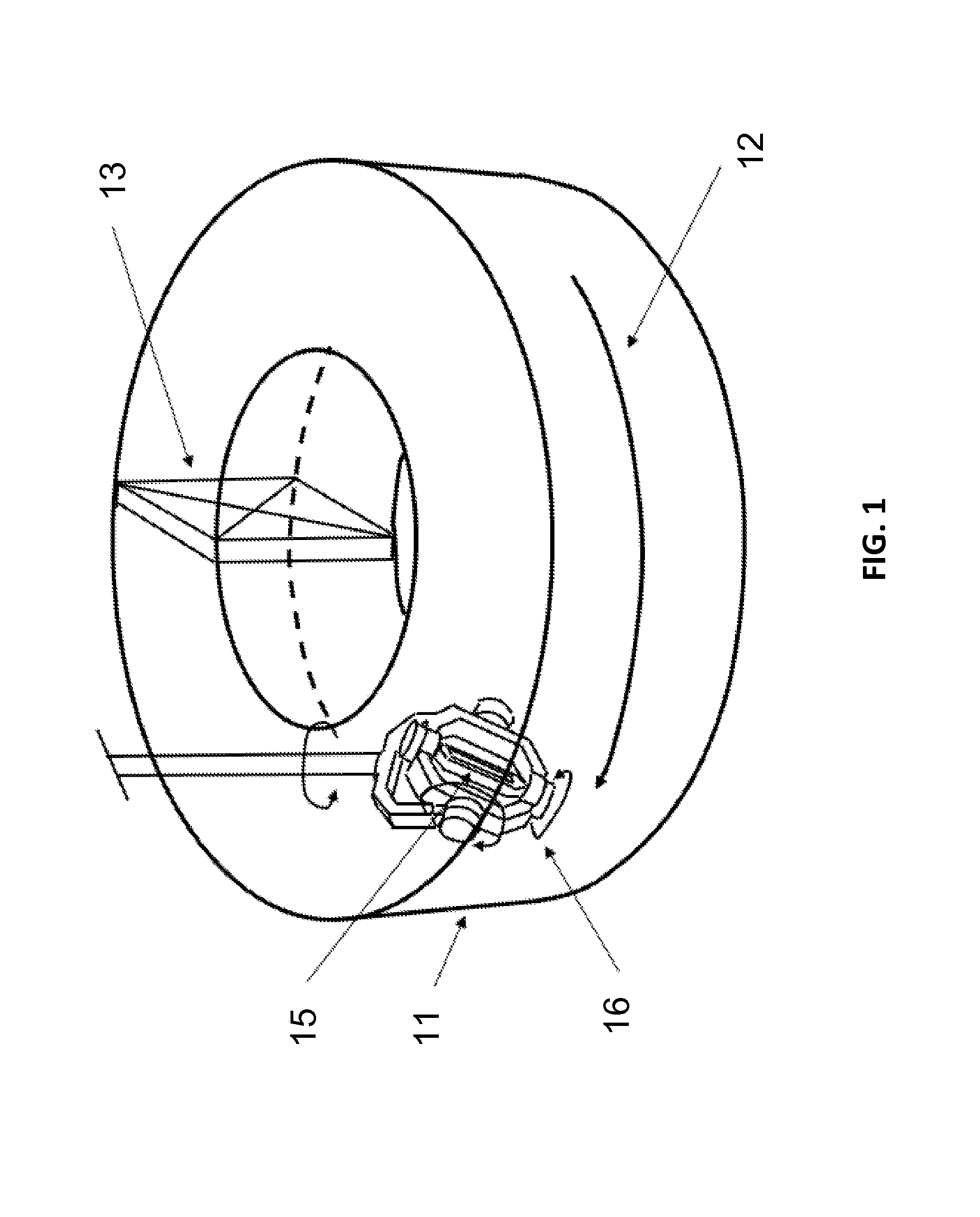

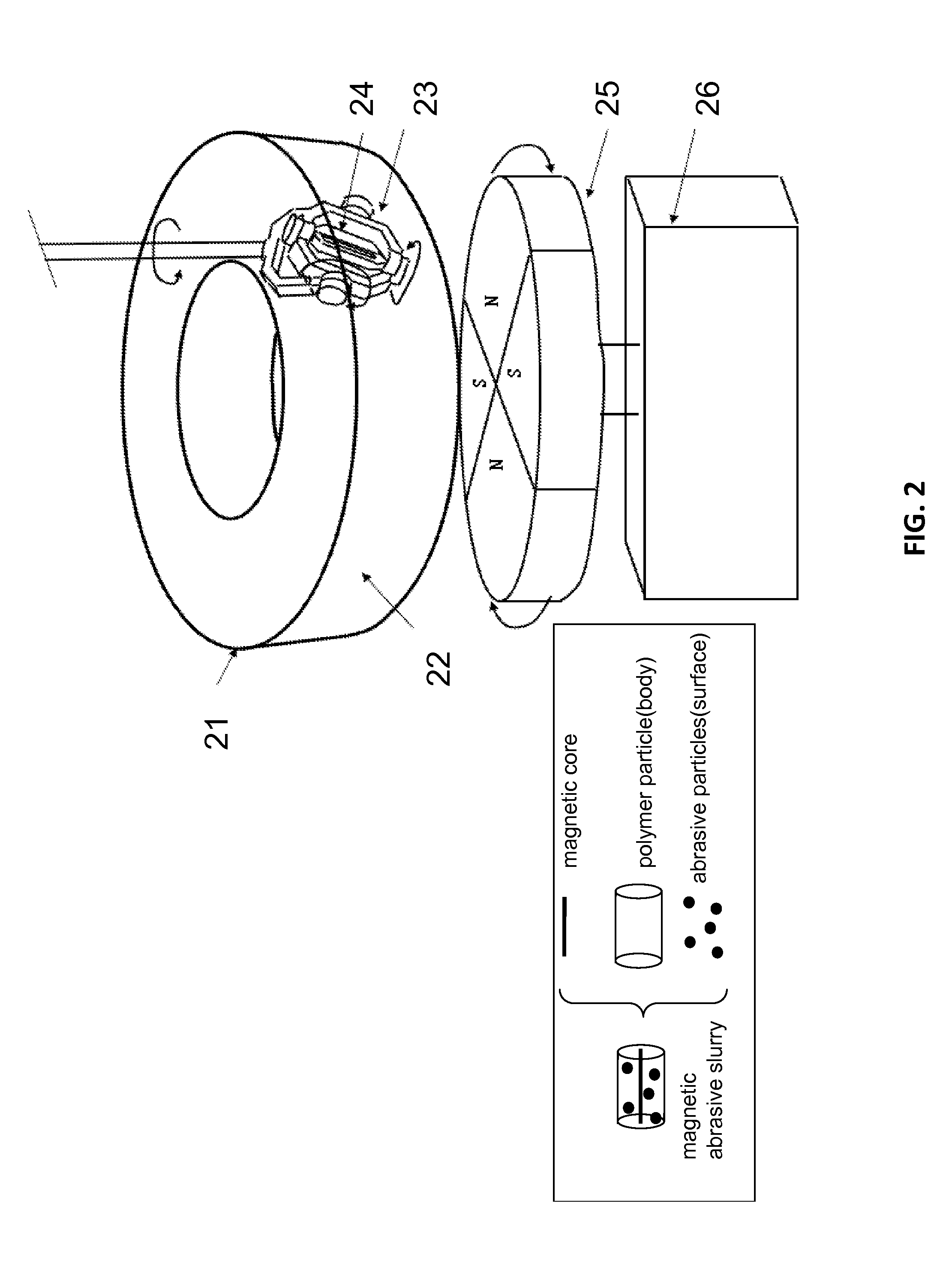

[0012]FIG. 1 illustrates an exemplary embodiment of the present invention. The automatic polishing device in this embodiment comprises a circular container 11 containing an abrasive slurry 12 which comprises a plurality of abrasive particles and a carrying liquid driven by a liquid pump 13, wherein the liquid pump 13 drives the abrasive slurry to form abrasive slurry flow 12 in the circular container 11. A workpiece 15 to be polished is mounted in a three-axis rotary stage 16 immerged inside the abrasive slurry flow 12. The orientation of the workpiece 15 varies in a controlled manner by the three-axis rotary stage 16 capable of automatic adjustment to facilitate a gentle and uniform surface finish of the workpiece 15. In one example, the workpiece 15 is a complex-curved-profile aluminum article at dimension of less than 50(L)×50(W)×50(H)mm3. It is immerged in the abrasive slurry 12 containing 600 mesh silicon carbide (SiC) abrasive particles, other polymers such as silicone-based e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com