Extraction of metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

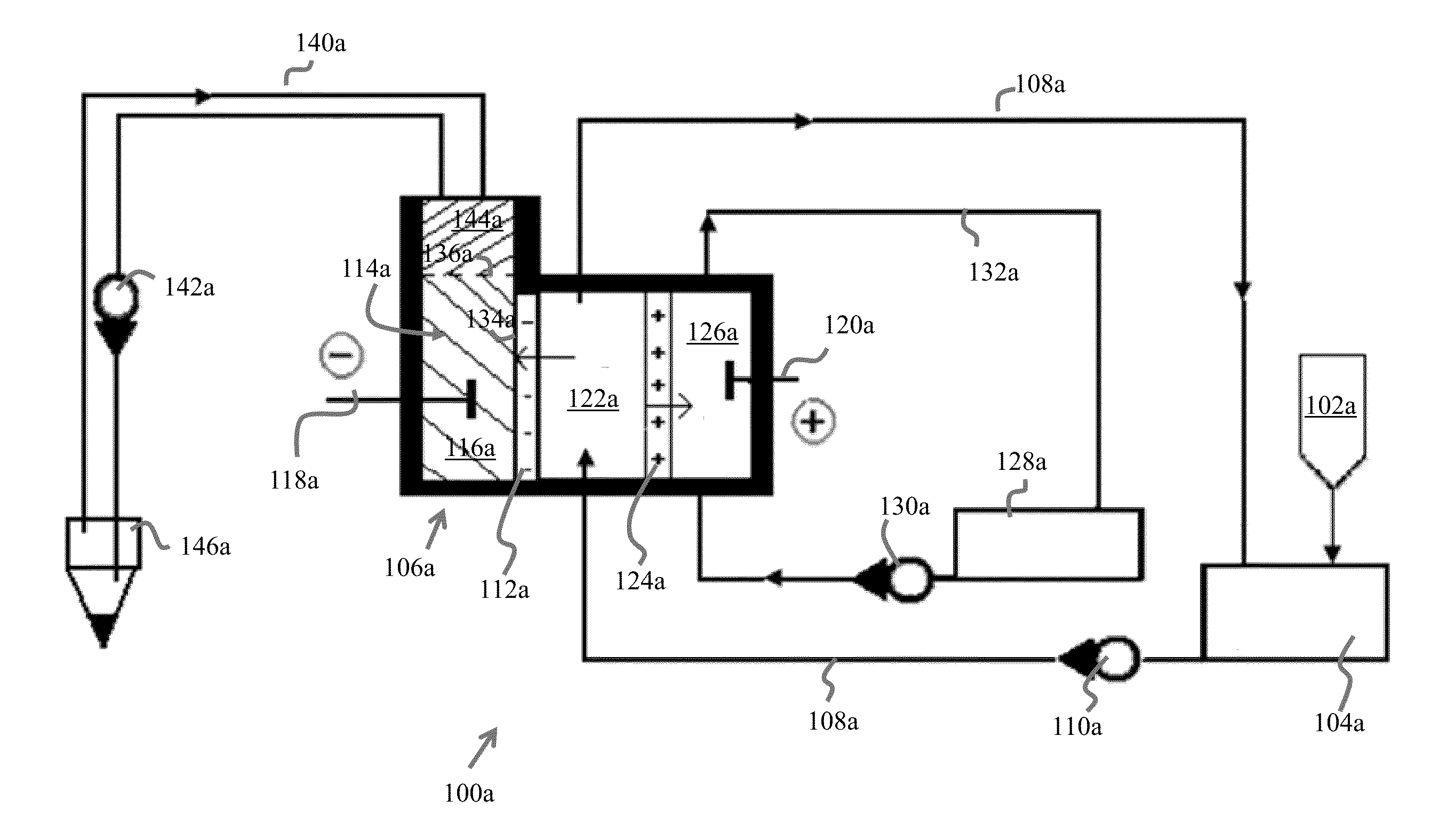

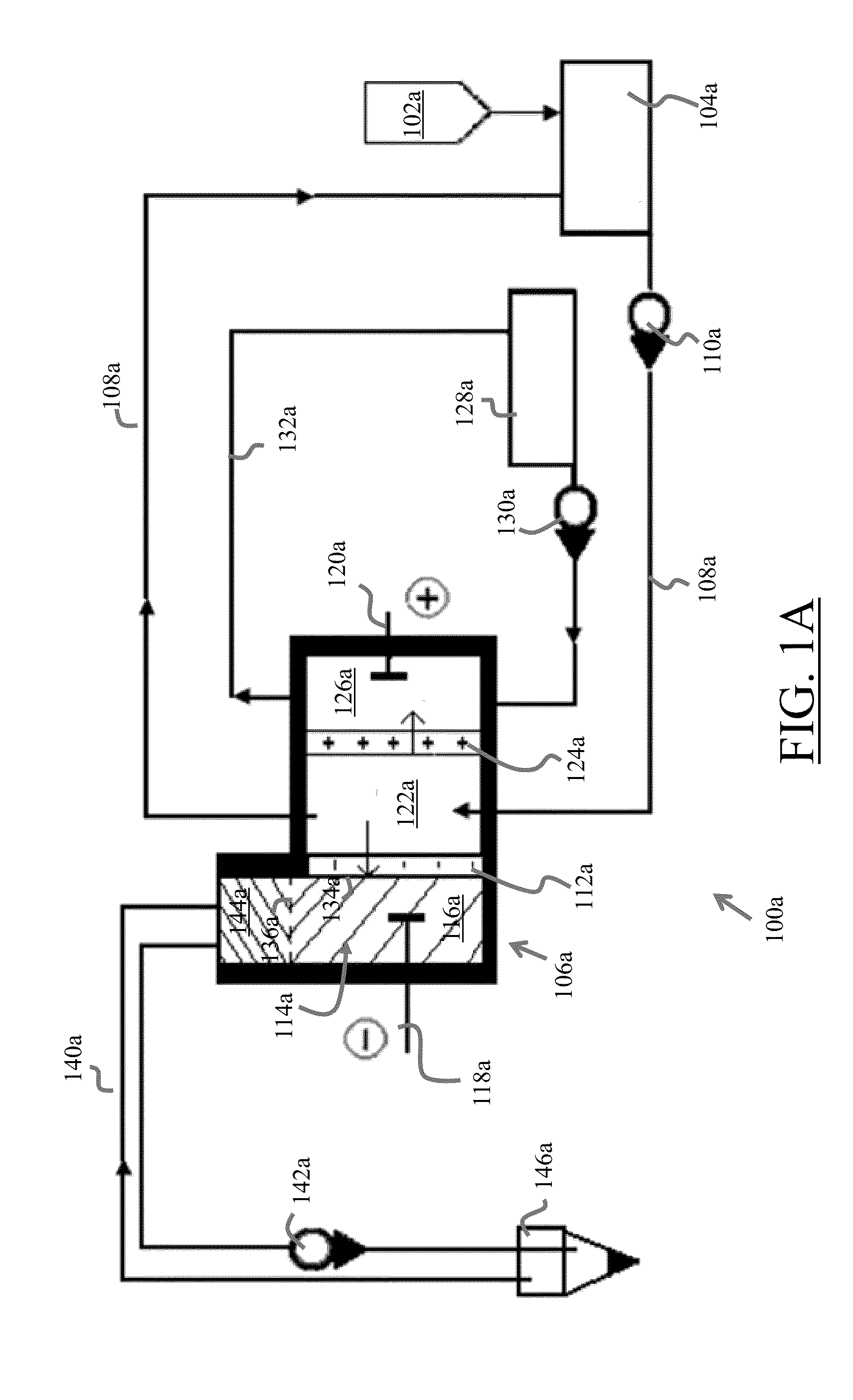

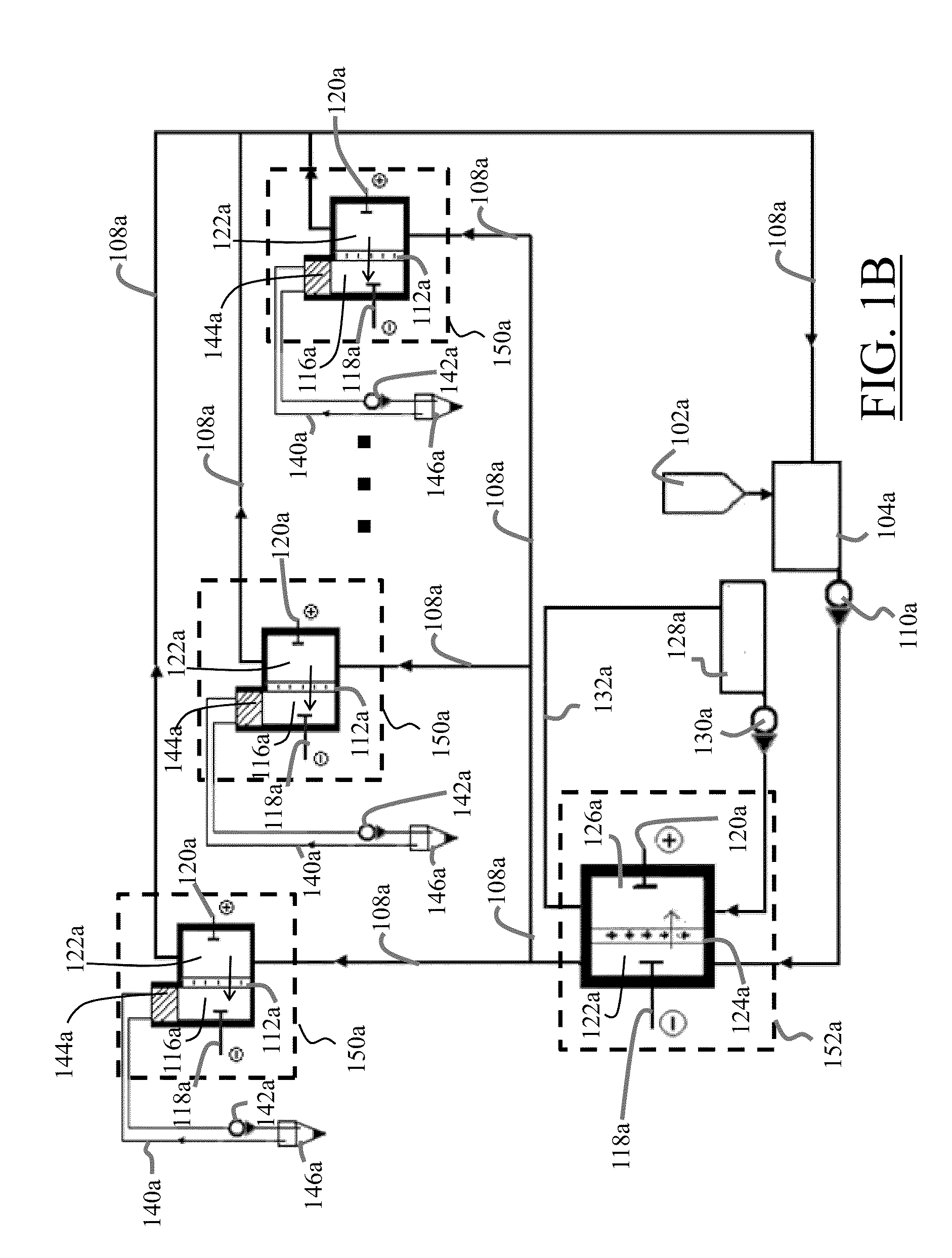

[0065]FIG. 1A illustrates the water tank of the unit where magnesium chloride water solution having 50 g / l concentration is filled.

[0066]Electro-dialyzer characteristics are as followings:

[0067]Voltage 10 V

[0068]Membrane types MK-40, MA-40, MB-1E

[0069]Membrane surface 100 cm2

[0070]Membranes numbers 3 (one membrane from each kind)

[0071]Cathode chamber volume 30 cm3

[0072]The distance between membranes 0.3 cm

[0073]Current density 0.03 A / cm2

[0074]The cathode chamber 114 of the electro-dialyzer 106 is mercury filled (liquid metal 116), which serves as a cathode 116, while a stainless steel plate (120) serves as an anode 120. A removal medium layer 144 covers the cathode 116 and functions to remove the nano-particle metallic elements M from the top skin surface 136 of the cathode chamber 114 conductive liquid 116. The aqueous electrolyte solution is filled into the circulation tank 104 with the approximate, non-limiting exemplary rate of 1 liter / minute, from which it is pumped 110a and is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electric charge | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com