Conductor composite material in high-frequency communication cable and high-frequency communication cable made by conductor composite material

A high-frequency communication and composite material technology, which is applied in the field of high-frequency communication cables, can solve the problems of complex manufacturing process, poor flexion and extension coefficient, and not easy to bend, so as to save metal materials, increase flexion and extension ratio, and enhance tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

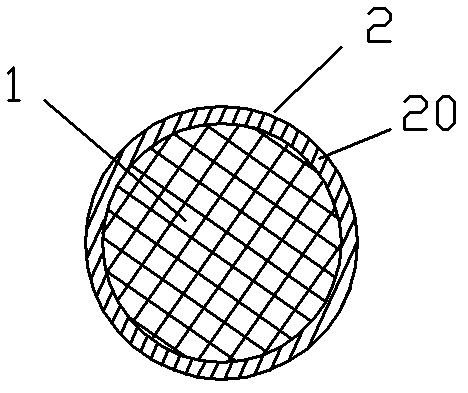

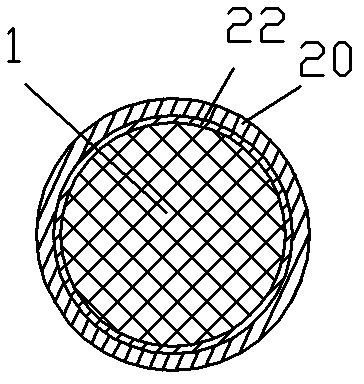

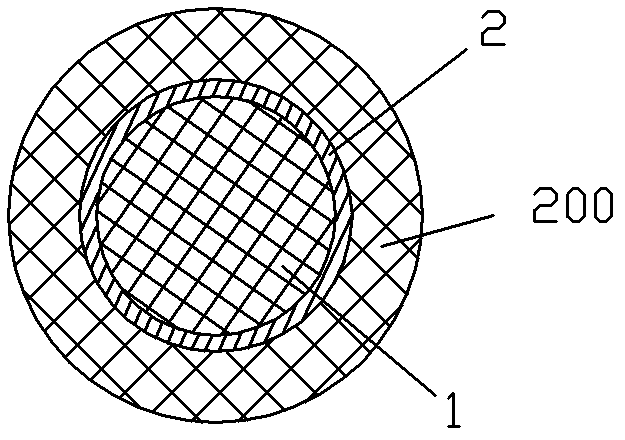

[0035] refer to Figure 1-Figure 13 , the conductor composite material in the high-frequency communication cable of the present invention, each conductor composite material is formed by plating a metal coating 2 on the outside of a round monofilament or a round thin tube 1 made of a plastic core base material, The diameter of the round monofilament or round thin tube 1 is greater than 0.1 mm and less than 2 mm, and the thickness of the metal coating 2 is greater than 2 microns and less than 0.2 mm. The metal coating 2 includes at least a surface metal coating 20 .

[0036] By replacing the metal strip with the plastic wire core base material, the production cost is effectively reduced, and since the transmission of high-frequency signals is only carried out on the surface of the conductor, the metal coating can realize the function of transmitting signals.

[0037] Further, the plastic core base material is high temperature tough epoxy resin, polyacrylonitrile or polycarbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com