Towels of micro fibers of polyester/polyamide bi-components and the method of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

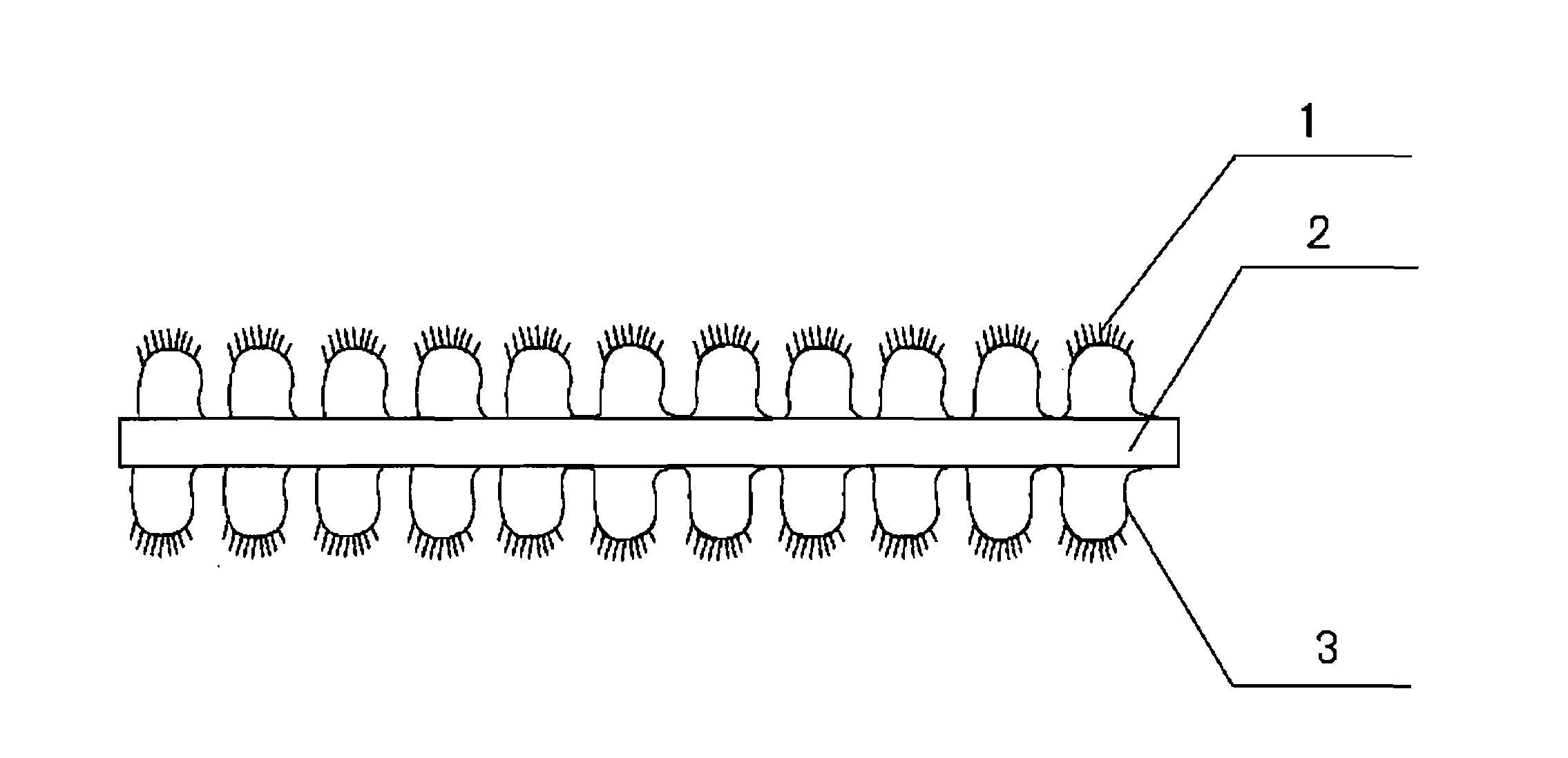

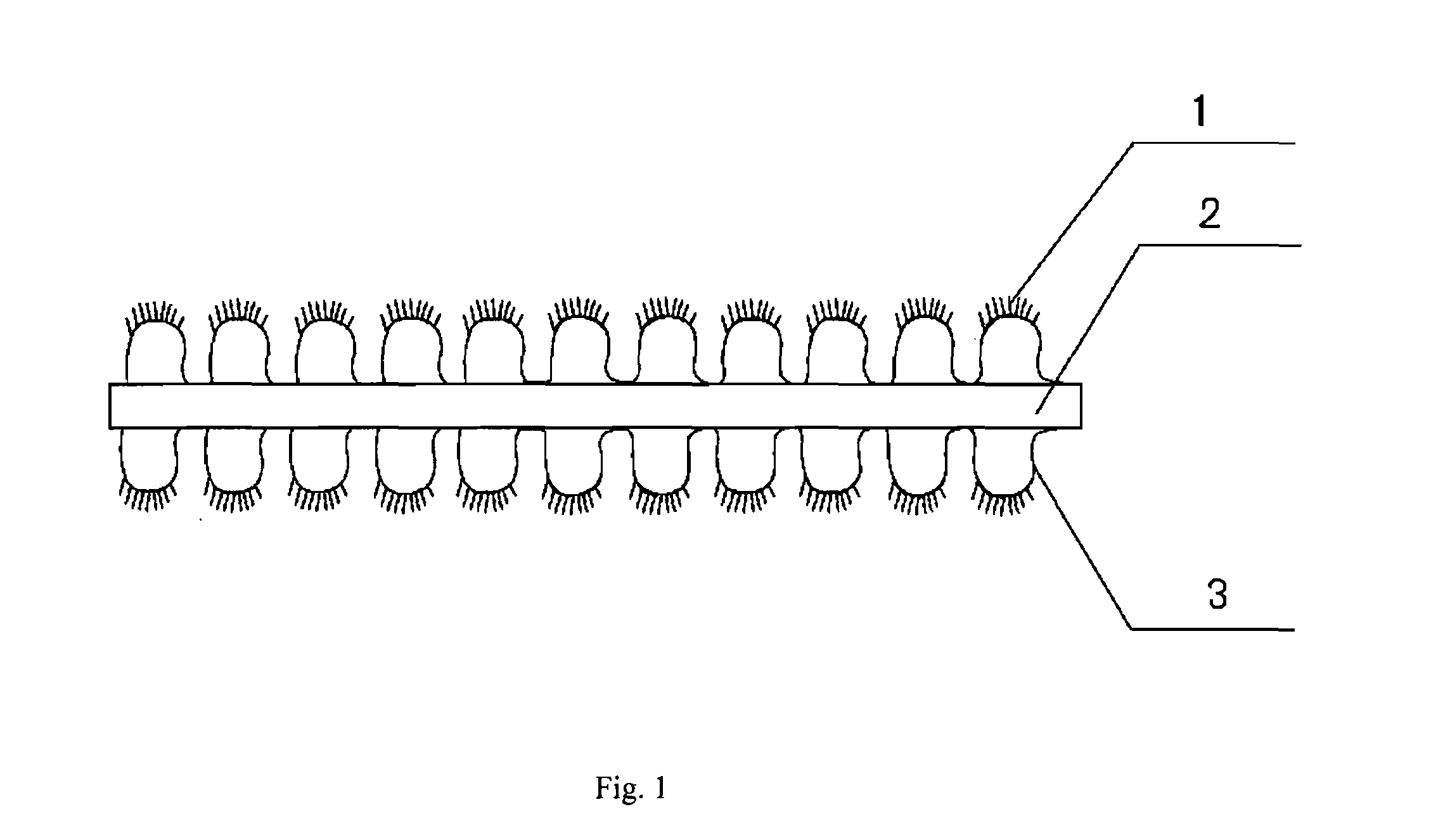

[0026]As shown in FIG. 1, in one embodiment, a towel of polyester / polyamide bi-components micro fibers may be a wrap knitted fabric that has a double-sided base fabric 2 made of polyester / polyamide bi-components micro fibers that are treated by a chemical splitting process. Both sides of the base fabrics 2 may have loop piles 3. The density of the loop piles 3 may be at least 10 per square centimeter. Every loop pile 3 may contain at least 1 single-thread loop. The bottom sections of loop piles 3 are connected to the base fabric 2. A plush-like structure 1 may be made by fracturing loops from the top of the loop piles 3 inwardly to about ⅓ of the thickness of the loop piles 3 from the top of the loop piles 3. All the loop piles 3 may have loops fractured at about the same position. The fractured fibers may form an outward plush-like structure 1. The sanding paper used for the sanding treatment may be 400 grits. The rotation speed of the sand paper may be 1000 rpm, and the speed of f...

example 2

[0029]As shown in FIG. 1, in one embodiment, a towel of polyester / polyamide bi-components micro fibers may be a wrap knitted fabric that has a double-sided base fabric 2 made of polyester / polyamide bi-components micro fibers that are treated by a chemical splitting process. Both sides of the base fabrics 2 may have loop piles 3. The density of the loop piles 3 may be at least 10 per square centimeter. Every loop pile 3 may contain at least 1 single-thread loop. The bottom sections of loop piles 3 are connected to the base fabric 2. Only the loop piles 2 on one side of the base fabrics 2 are sanded. The sanding process may start at the top of the loop piles 3 and moves inwardly to about 1 / 10 of the thickness of the loop piles 3. The fractured loops of the loop piles 3 may form outward plush-like structures 1. The sanding paper used for the sanding treatment may be 500 grits. The rotation speed of the sand paper may be 1200 rpm, and the speed of fabric advancement may be 10 meters per...

example 3

[0034]As shown in FIG. 1, in one embodiment, the loop piles 3 of the both sides of the base fabric 2 may be sanded. On one side, the sanding process may start at the top of the loop piles 3 and moves inwardly to about 5 / 10 of the thickness of the loop piles 3 from the top. The sanding paper used for the sanding treatment may be 300 grits. The rotation speed of the sand paper may be 800 rpm, and the speed of fabric advancement may be 8 meters per minute, and the sanding angle may be 70 degrees. On the other side, the sanding process is started at the top of the loop piles 3 and moves inwardly to about 1 / 10 of the thickness of the loop piles 3. The sanding paper used for the sanding treatment may be 500 grits. The rotation speed of the sand paper may be 1200 rpm, and the speed of fabric advancement may be 10 meters per minute, and the sanding angle may be 5 degrees.

[0035]The advantages of the towels made from the above mentioned method may be that the loop piles on both sides of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com