Lignin-derived thermoplastic co-polymers and methods of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Controlled Crosslinking of Lignin

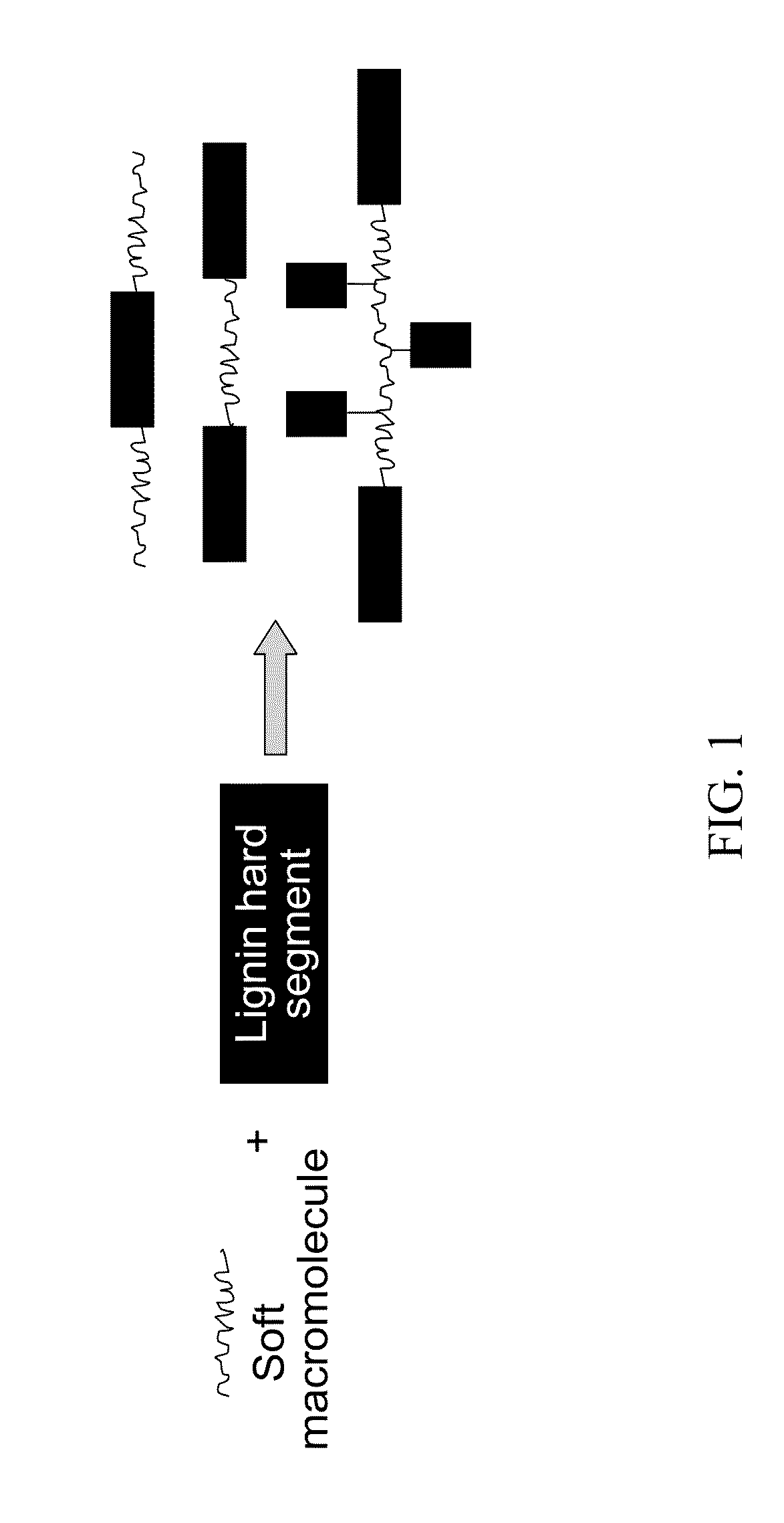

[0059]The process for crosslinking lignin described in this example can be generally summarized by the following reaction scheme:

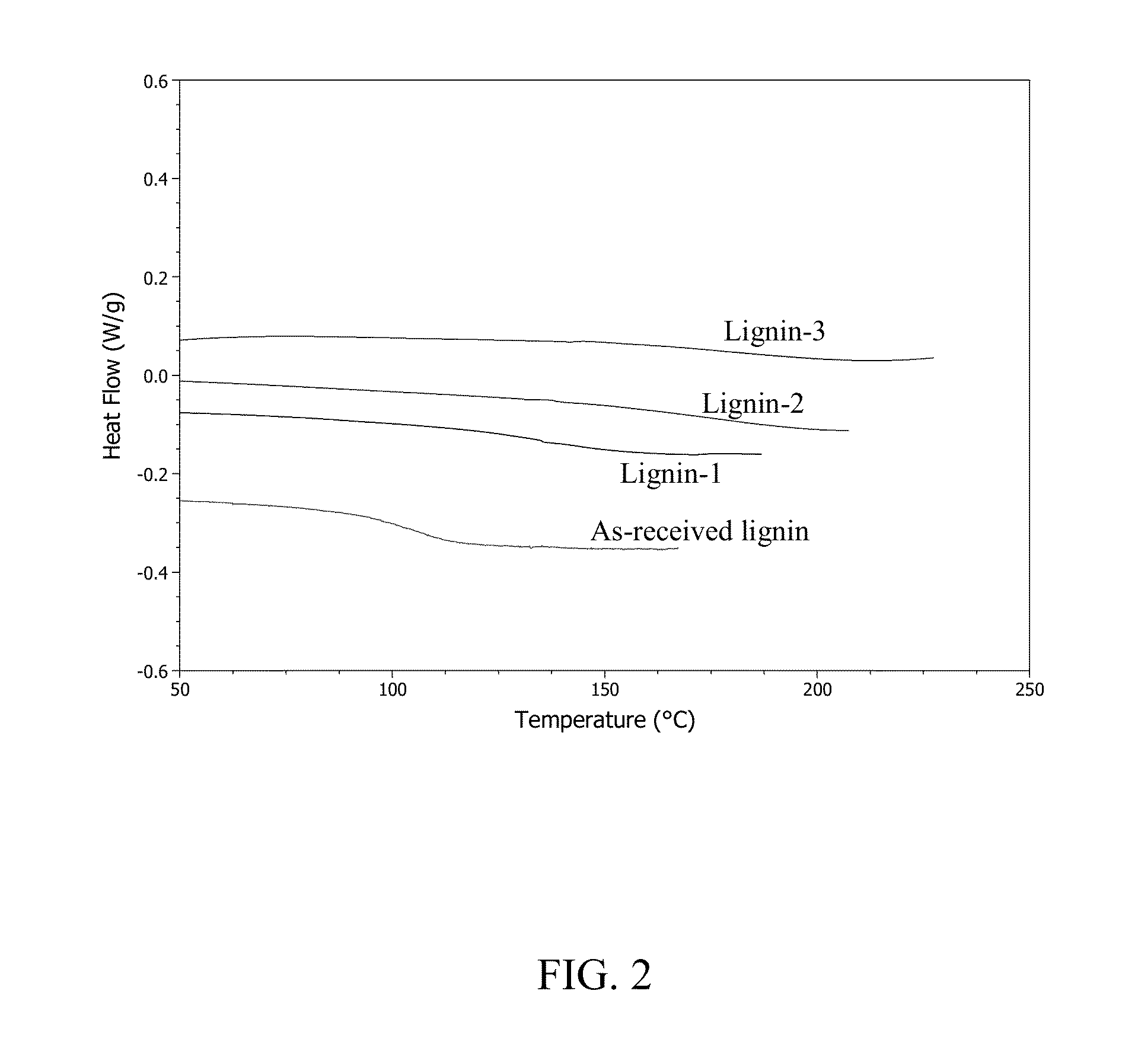

[0060]A 1-L round-bottomed flask was equipped with a large magnetic stir bar and placed in a heating mantle. 100 g of organosolv lignin (as received, not dried, having a MW of 1840 g / mol, polydispersity index (ratio of weight average to number average molecular weights) of 122, and Tg of 108° C.) were added to the flask. Lignin was dissolved using 200 mL NaOH solution (pH>14) and 300 mL of millipure water, for a final concentration of 16 wt % solids. Once the lignin appeared fully dissolved, the flask was fitted with an addition funnel. 120 mL of formalin solution (10 wt % in buffered solution) were added dropwise to the lignin solution with stirring, at 80° C. After two hours, an additional 120 mL of formalin (10 wt % in buffer solution) were added to the reaction. Reaction continued for four additional hours (six hours to...

example 2

Copolymerization Reactions of Crosslinked Lignin

[0063]I. Copolymerization Reaction of Crosslinked Lignin with Carboxy-Functionalized Polybutadiene

[0064]The process for copolymerizing crosslinked lignin with carboxy-functionalized polybutadiene described in this example can be generally summarized by the following reaction scheme. The long curved lines shown in the final product represent carboxy-functionalized polybutadiene that has been attached to the crosslinked lignin.

[0065]As-received lignin was reacted with dicarboxy-terminated polybutadiene soft segment (Mn 4,200 g / mol) in the presence of formalin at 1:1 F / L ratio with KOH in 1,4-dioxane solvent (with KOH concentration of 2.4 mmol / 40 mL solvent) for 24 hours at 100° C. Different amounts of lignin were loaded to obtain 9, 13, 17, and 22 wt % lignin, respectively, in the feed compositions. All the resulting lignin-polybutadiene copolymers were isolated via precipitation into methanol and dried under reduced pressure at 50° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com