Method and system for the torrefaction of lignocellulosic material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

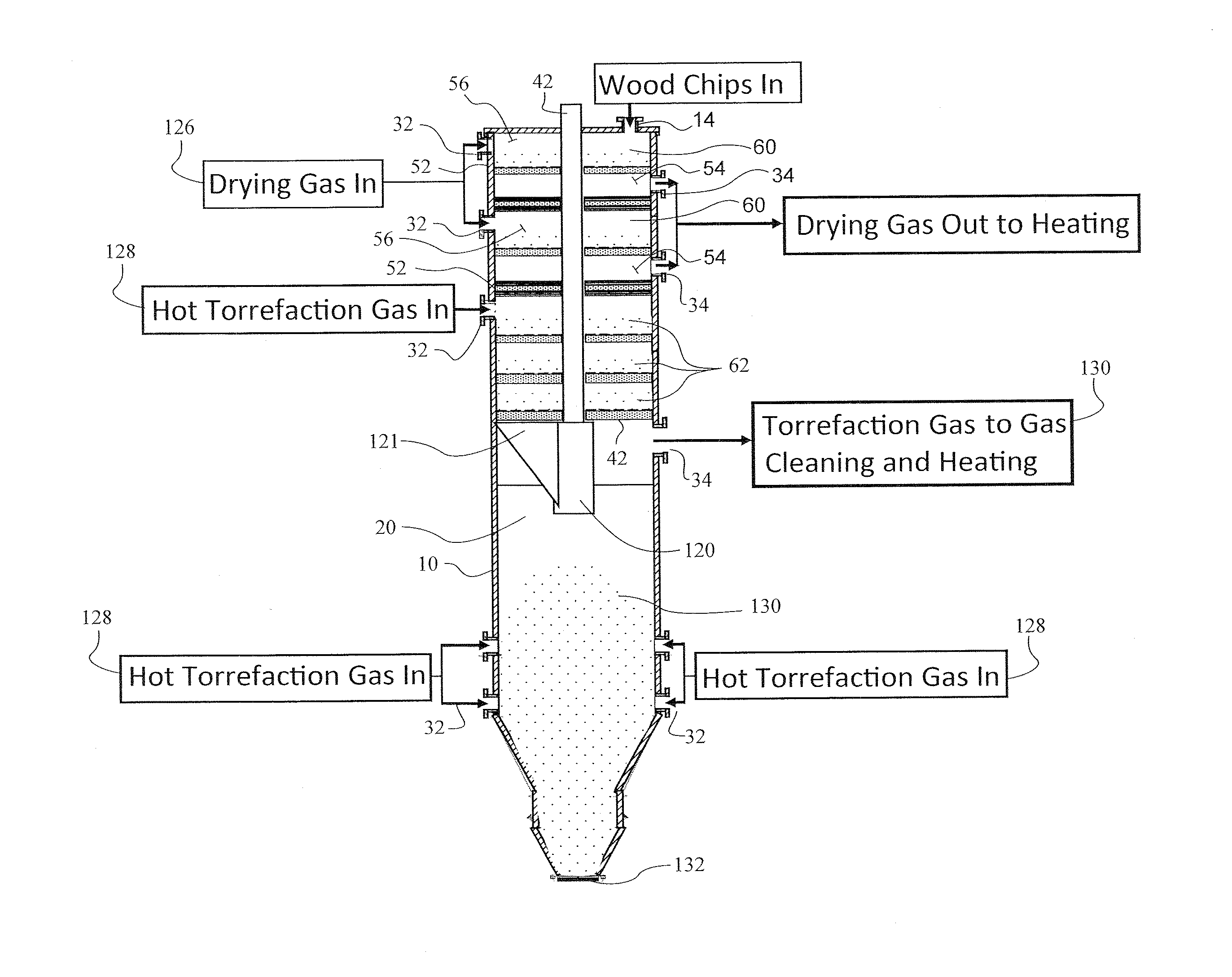

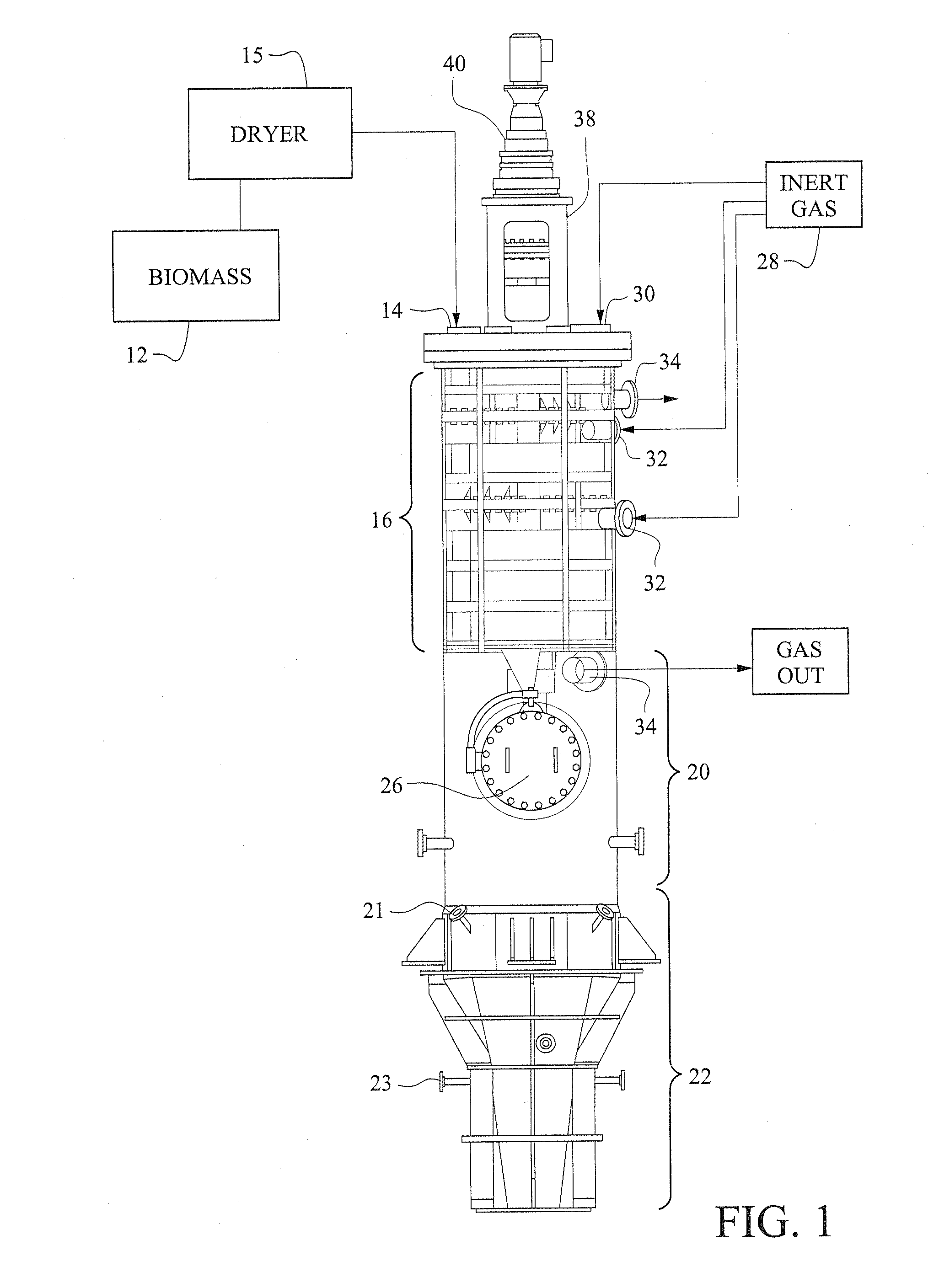

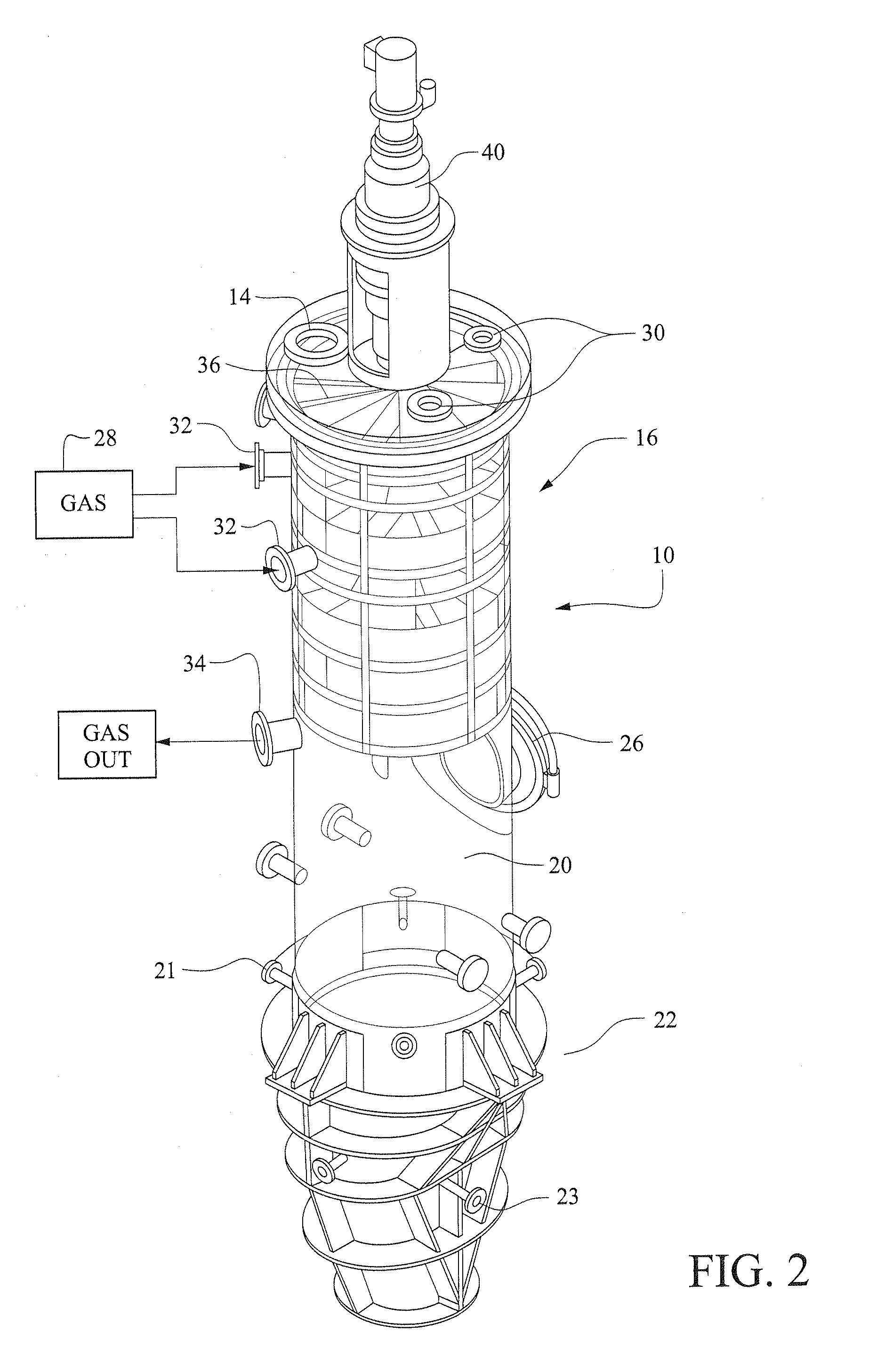

[0050]FIGS. 1 to 4 illustrate an embodiment of a pressurized treatment vessel 10 for receiving, drying, treating by torrefaction, and cooling biomass material from a supply of biomass 12 through an upper inlet 14. The biomass may be wood chips, wood pulp or other comminuted cellulosic material. The biomass is dried, subjected to a torrefaction process and cooled to produce torrefied biomass.

[0051]The biomass may be fully or partially dried in an external dryer 15 before entering the vessel. After passing through the upper inlet, the biomass enters an upper tray in a stack 16 of trays. The trays provide a cascade of moving beds to dry and treat the biomass. The upper trays may be used to dry the biomass. Lower trays may be used to subject the biomass to a torrefaction treatment. An insulating tray may divide the drying trays from each other and the torrefaction trays.

[0052]The upper inlet 14 to the pressurized vessel may be coupled to a continuous feed, pressure isolation device, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com